Composite material for mining and method for preparing steel structure and wooden stack erection from it

A composite material and steel structure technology, applied in the field of erecting wooden stacks, can solve problems such as hidden safety hazards in mine production, damage to the ecological environment, and affect roadway ventilation, etc., achieving significant economic and environmental benefits, social and environmental benefits, and labor low intensity effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

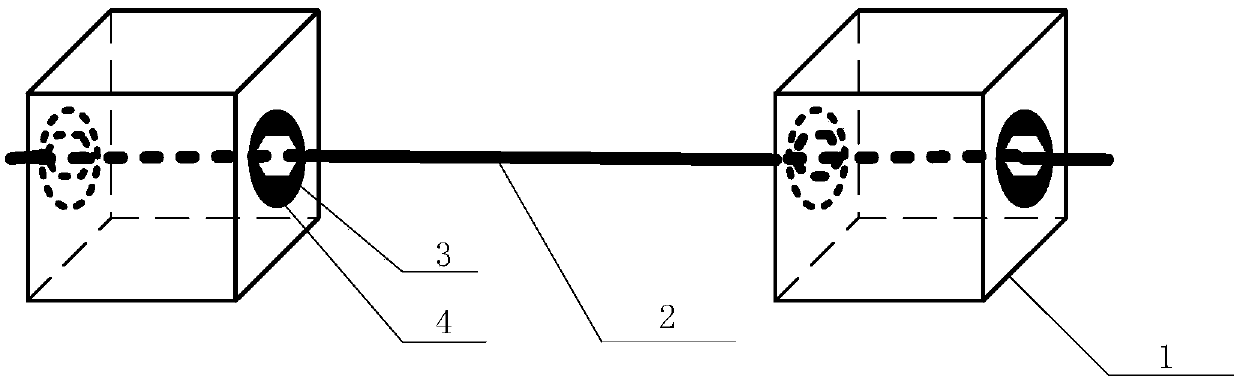

[0039] Such as figure 2As shown, the present embodiment provides a mine-used composite steel structure, and the two ends of the short beam 2 of the steel structure penetrate into two different bearing blocks 1 ( figure 2 In the tension holes of the middle left and right pressure blocks 1), the two pressure blocks 1 are connected; and the positioning device is used to fix the pressure block 1 and the short beam 2.

[0040] In this embodiment, the positioning device includes a gasket 4 and a nut 3, both of which are sleeved on the short beam 2, one side of the gasket 4 is in contact with the end face of the pressure block 1, and the nut 3 and the gasket 4 are in contact with each other. The other side abuts against each other; preferably, gaskets 4 and nuts 3 are provided on the same side of the two bearing blocks 1 .

[0041] In this embodiment, the tension holes pass through the symmetrical two ends of the pressure block 1 for the penetration of the short beam 2; the gasket...

Embodiment 2

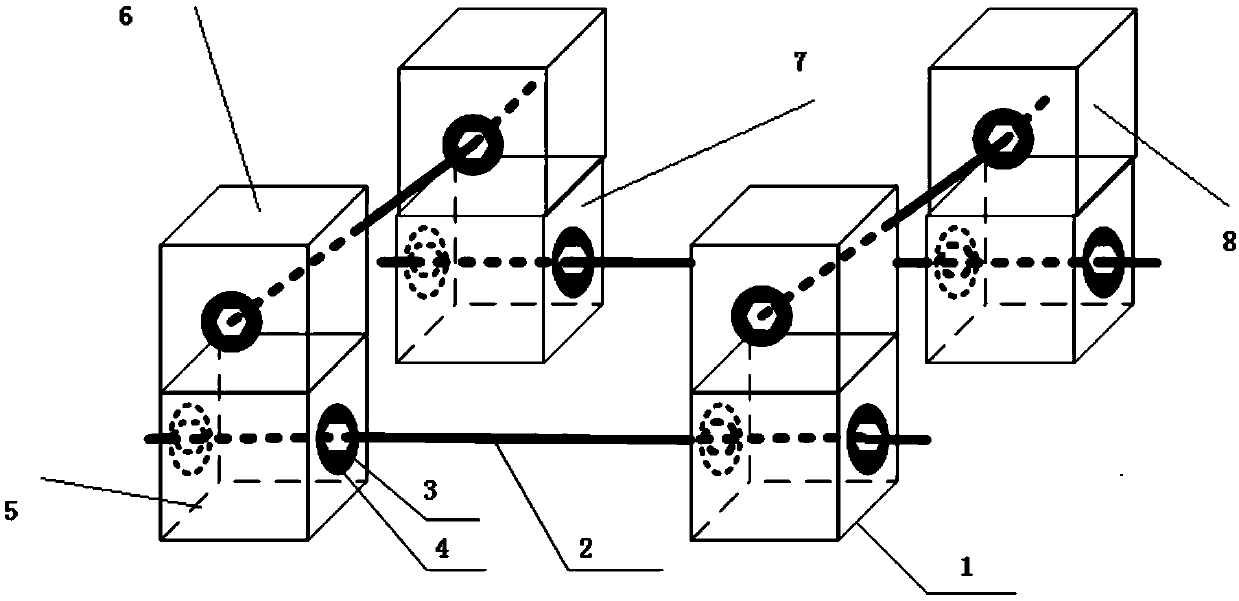

[0045] Such as image 3 As shown, this embodiment provides a structure for erecting wooden cribs using a mining composite material steel structure. The wooden crib adopts a mining composite material steel structure. I won't repeat them here.

[0046] In this embodiment, the composite steel structure for mining is erected according to the shape of a "well" wooden stack; the pressure blocks 1 of the composite steel structure for mining on the wooden stack are in close contact with each other, that is, one part of the second steel structure 6 The pressure-bearing block 1 is placed on a pressure-bearing block 1 of the first steel structure 5, and another pressure-bearing block 1 of the second steel structure 6 is placed on a pressure-bearing block 1 of the third steel structure 7; the fourth A pressure-bearing block 1 of the steel structure 8 is placed on another pressure-bearing block 1 of the first steel structure 5, and another pressure-bearing block 1 of the fourth steel stru...

Embodiment 3

[0050] A method for preparing a steel structure using a mining composite material comprises the following steps:

[0051] 1) Weigh the isocyanate, polyether polyol, fly ash, catalyst and diluent according to the required ratio, mix them, and stir them evenly at high speed to obtain a mixed slurry;

[0052] The catalyst is a tertiary amine catalyst; the diluent is silicone oil.

[0053] 2) Pour the mixed slurry in step 1) into a mold with a specification of 150mm×150mm×150mm, and make a pressure-bearing block after consolidation for 55 hours; reserve a tension hole on the pressure-bearing block; the tension hole runs through the bearing The symmetrical ends of the pressing block are used for the penetration of short steel bars.

[0054] 3) Insert the two ends of the short steel bars with a diameter of 20mm and a length of 1.2m into the tension holes of the pressure-bearing blocks in two different steps 2) to connect the two pressure-bearing blocks, and use gaskets and The nut...

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

| compressive strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com