High-carbon spheroidized sorbite cutting tool steel with high surface hardness and excellent bending performance and production method of high-carbon spheroidized sorbite cutting tool steel

A production method and high surface technology, applied in the field of high carbon spheroidized sorbite cutting tool steel, can solve the problems of serious surface decarburization and oxidation, high production efficiency, unsuitable for bending, etc., and achieve high surface hardness and good wear resistance. , low cost, excellent wear resistance

Active Publication Date: 2021-10-29

ANGANG STEEL CO LTD

View PDF15 Cites 0 Cited by

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

[0013] The invention provides a high-carbon spheroidized sorbite cutting tool steel with high surface hardness and excellent bending performance and a production method thereof, which overcomes the problems of severe decarburization and oxidation on the surface of the existing cutting tool steel and is not suitable for bending. Cutting tool steel has low Si content, smooth surface, no grain boundary oxide layer and decarburization layer, tensile strength 700MPa~800MPa, yield strength ratio below 50%, 180°bend without cracking, excellent bending performance, no need for heat treatment surface hardness Above 48HRC, excellent wear resistance, high production efficiency and low cost

Method used

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

View moreImage

Smart Image Click on the blue labels to locate them in the text.

Smart ImageViewing Examples

Examples

Experimental program

Comparison scheme

Effect test

Embodiment 3

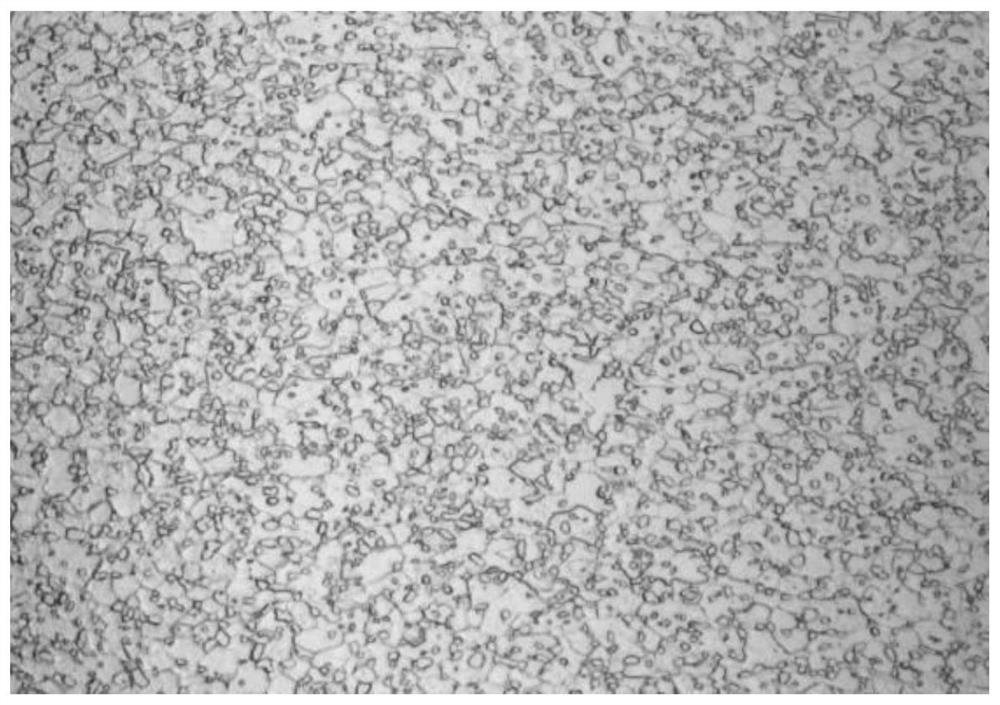

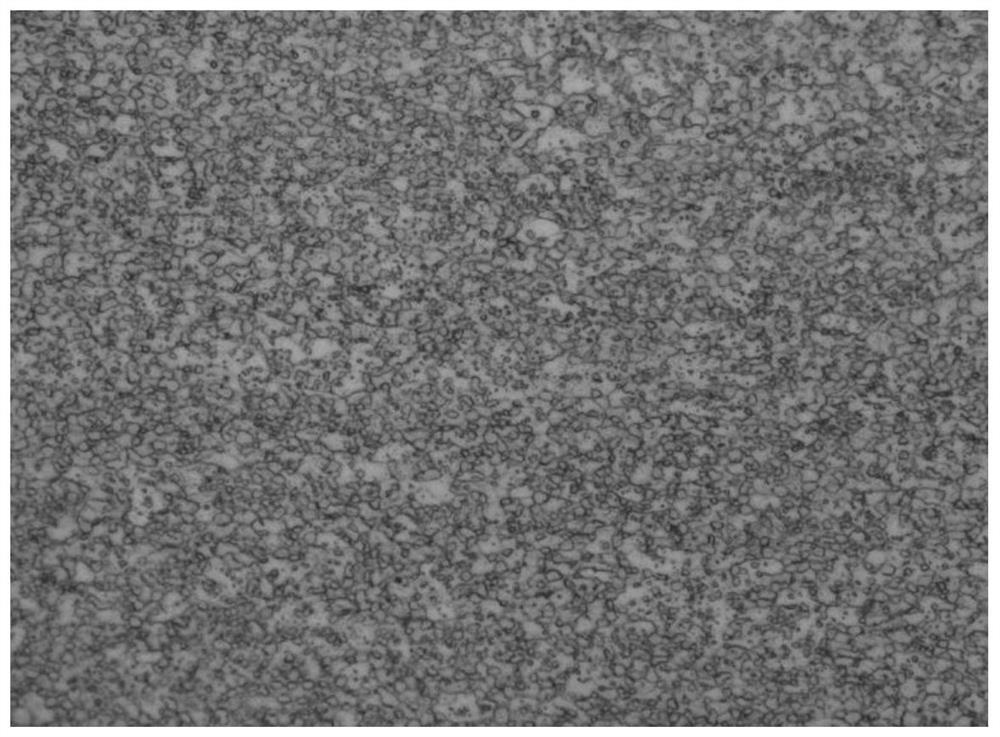

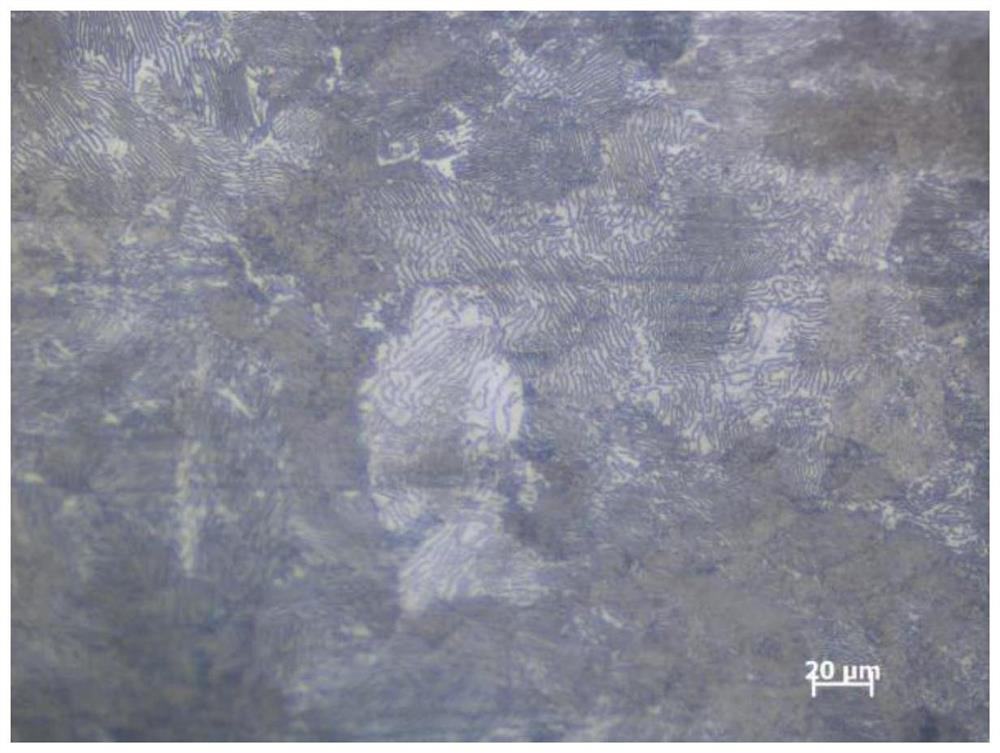

[0119] Example 3 The spheroidized sorbite microstructure of the steel sheet (1000 times) is as follows figure 1 As shown, the microstructure of the hardened particle layer under the surface of the steel plate in Example 3 (1000 times) is as follows figure 2 shown, image 3 It is the microstructure map of the steel plate of Comparative Example 1 (500 times).

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More PUM

| Property | Measurement | Unit |

|---|---|---|

| tensile strength | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Login to View More

Abstract

The invention relates to high-carbon spheroidized sorbite cutting tool steel with high surface hardness and excellent bending performance and a production method of the high-carbon spheroidized sorbite cutting tool steel. A steel plate is prepared from the following chemical components: 0.60%-1.0% of C, less than or equal to 0.1% of Si, 0.4%-1.5% of Mn, 0.0005%-0.05% of Ca, 0.01%-0.5% of Re, less than or equal to 0.06% of Al, less than or equal to 0.05% of Mg, more than or equal to 0.3 of Ca / S, more than or equal to 1 of Ca / Mg, more than or equal to 0.02 of Ca / Re, 0.1%-1.0% of Sn, less than or equal to 0.020% of P, less than or equal to 0.015% of S and the balance of Fe and inevitable impurities. The produced cutting tool steel is low in Si content, smooth and clean in surface, free of a grain boundary oxidation layer and a decarburized layer, 700-800 MPa in tensile strength, 50% or below in yield ratio, free of cracking after being bent by 180 degrees, excellent in bending performance, free of heat treatment and excellent in abrasion resistance, and the surface hardness is 48 HRC or above.

Description

technical field [0001] The invention relates to the technical field of cutting tool steel production, in particular to a high-carbon spheroidized sorbite cutting tool steel with high surface hardness and excellent bending performance and a production method thereof. Background technique [0002] Due to the high carbon content of conventional cutting tool steel, the hot-rolled structure is mainly pearlite, which is brittle and cracks after bending at a small angle, so it is not suitable for bending into parts with complex shapes. With the development of the times, the use of cutting tool steel is becoming more and more extensive, and its performance requirements are also getting higher and higher. Not only does it require a hardness of 42HRC or more after heat treatment, but the processed shape is also becoming more and more complex. In order to meet the bending processing requirements of some complex parts, cold-rolled annealed cutting tool steel is usually used as the raw m...

Claims

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More Application Information

Patent Timeline

Login to View More

Login to View More Patent Type & Authority Applications(China)

IPC IPC(8): C22C38/02C22C38/04C22C38/06B22D11/16C21D1/26C21D6/00C21D8/02C22C33/06

CPCC22C38/02C22C38/04C22C38/002C22C38/005C22C38/06C22C38/008C22C33/06B22D11/16C21D1/26C21D6/005C21D6/008C21D8/0205C21D8/0221C21D8/0247C21D2211/009

Inventor 杨玉王英海张吉富任俊威丛志宇王杰马锋刘志伟张瑞琦郭晓宏

Owner ANGANG STEEL CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com