Thermal conversion high-temperature metallurgical furnace

A metallurgical furnace and heat conversion technology, applied in the field of metallurgy, can solve problems such as difficult water replenishment, body damage, body water loss, etc., and achieve the effects of avoiding infection, relieving lung dryness and dry cough, and improving cleaning effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

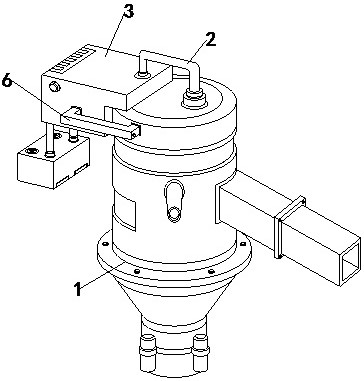

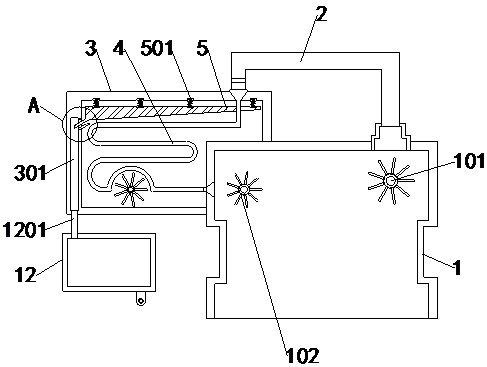

[0029] see Figure 1-Figure 9 , a heat conversion pyrometallurgical furnace, comprising a pyrometallurgical furnace 1 and an air duct 2, the air duct 2 is fixedly installed on the top of the pyrometallurgical furnace 1; the interior of the pyrometallurgical furnace 1 is located at the bottom of the air duct 2 A wind wheel 101 is connected in rotation;

[0030] Specifically, the high-temperature smelting treatment of metallurgical raw materials can be carried out through the high-temperature metallurgical furnace 1, and when the high-temperature metallurgical furnace 1 is performing smelting and processing, the heat flow will diffuse upwards, and the heat flow will be transported through the air delivery pipe 2, and the heat flow will be blown before entering the air delivery pipe 2. Moving the wind wheel 101 to make the wind wheel 101 rotate, the rotating wind wheel 101 can accelerate the speed of heat transfer;

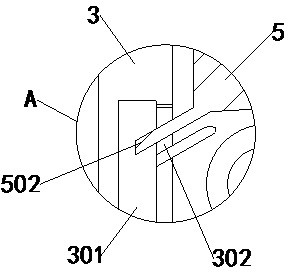

[0031] A heat transfer box 3 is fixedly installed in the upper...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com