Cell plane cooperative scheduling method for large equipment manufacturing and driving system

A technology for production scheduling and large-scale equipment, applied in manufacturing computing systems, genetic models, genetic laws, etc., can solve problems such as increased resource constraints and low production efficiency, and achieve obvious results.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0123] A scheduling method based on a cellular machine model specially applied to large-scale equipment manufacturing and driving systems, comprising the following steps:

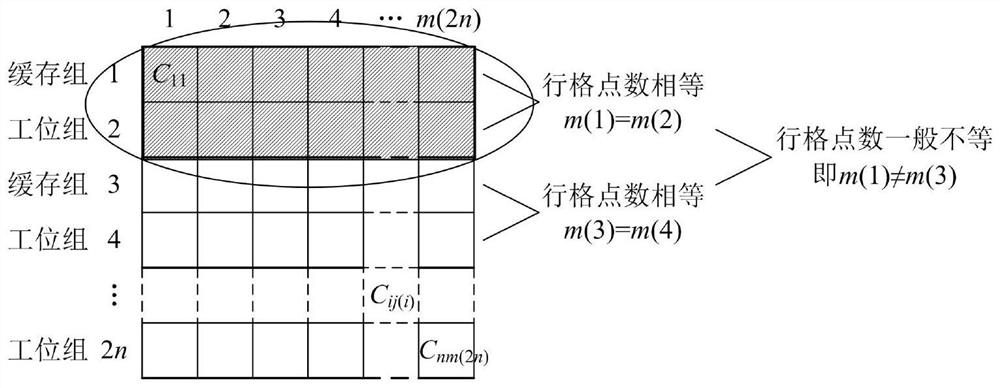

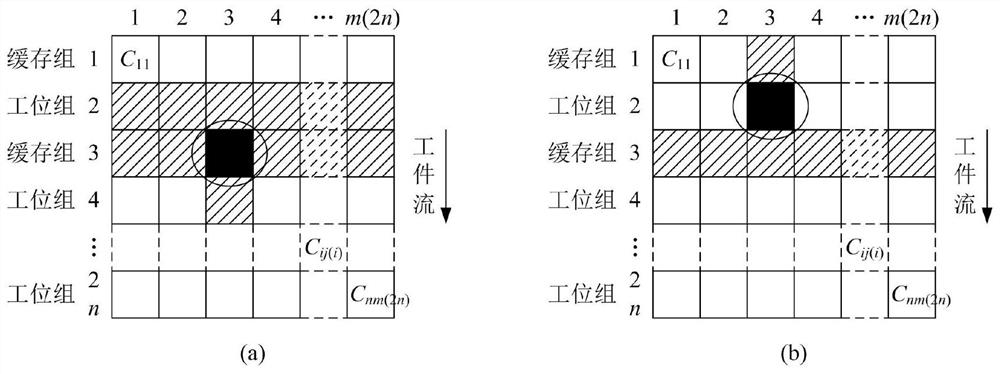

[0124] 1) Based on the basic principle of the standard cellular machine model, starting from the four basic components of cell space, cell state, neighborhood and local evolution rules, the operation is abstracted into a two-dimensional grid system across the production workshop, so as to construct Obtain a two-dimensional cellular machine model for production scheduling;

[0125] 2) The genetic algorithm is used to optimize the evolution rules of the production scheduling cellular machine model, and the chromosomes obtained after genetic algorithm optimization are used as the evolution rules of the cellular machine;

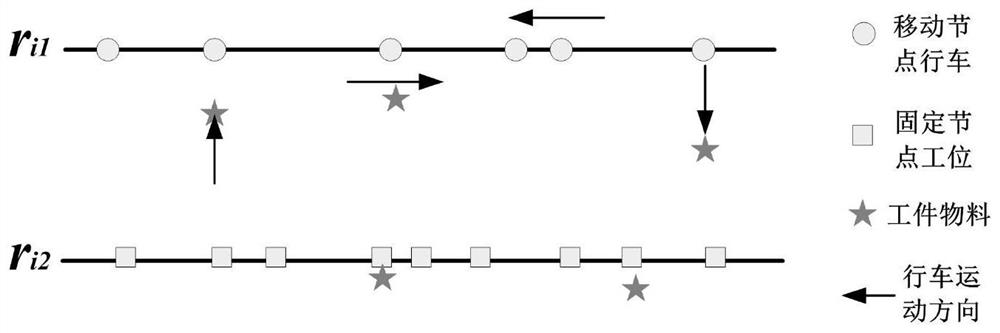

[0126] 3) According to the realistic characteristics of the traffic dispatching system, an irregular two-dimensional cellular computer traffic dispatching model with a certain flow direction ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com