Light-emitting assembly, manufacturing method thereof and light-emitting device

A technology of light-emitting components and manufacturing methods, which is applied in the direction of electrical components, electric solid-state devices, semiconductor devices, etc., can solve the problems of separation and falling off of light-emitting components, color deviation, mixed light, etc., to improve push-pull resistance performance, improve display quality, The effect of increasing the contact area

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

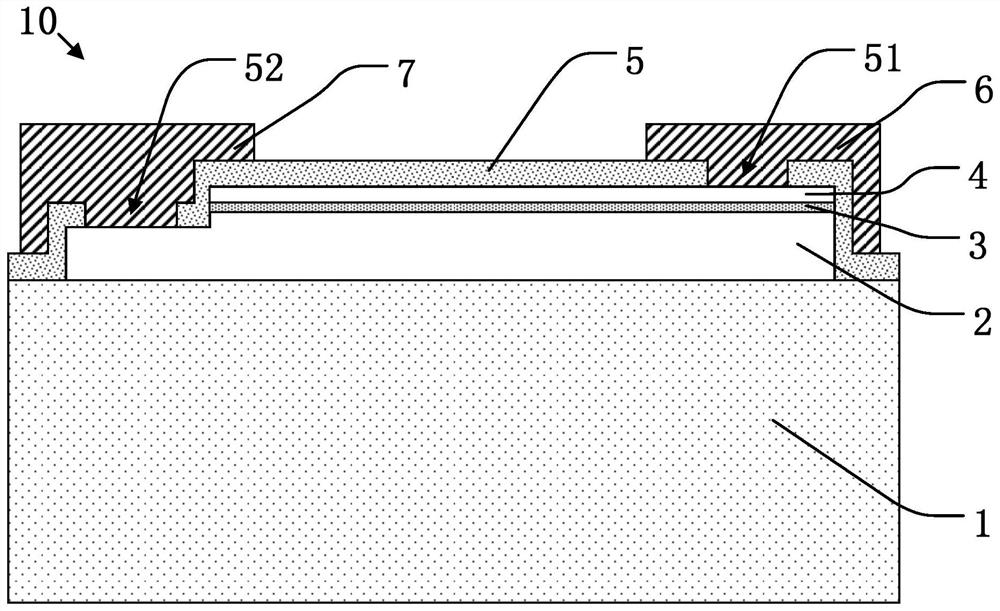

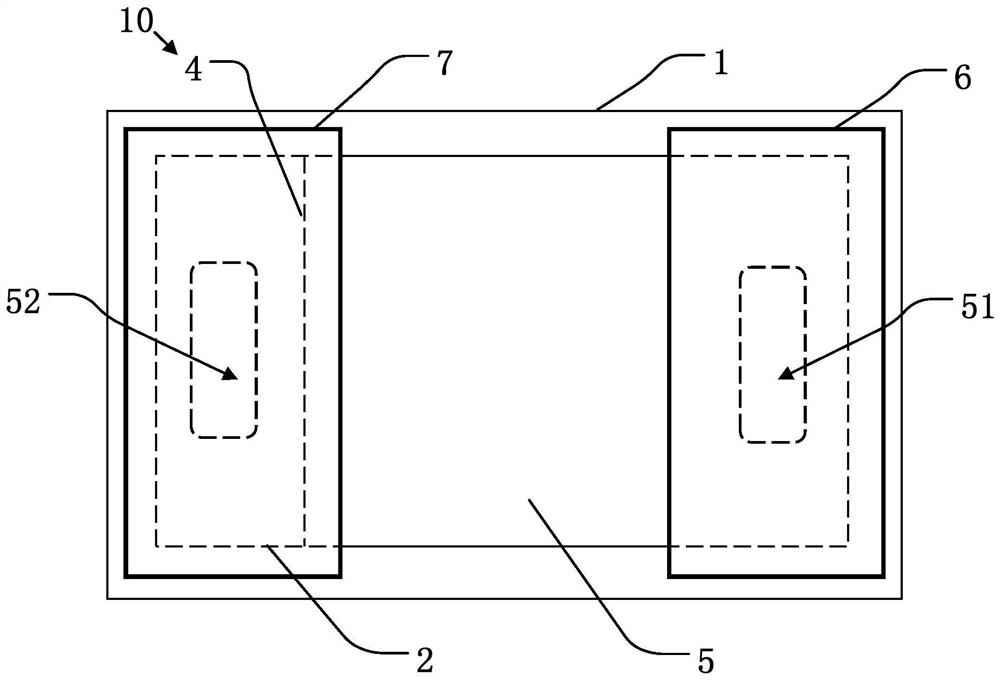

[0051] see figure 2 , image 3 , Embodiment 1 of the present application provides a light-emitting component 10 . figure 2 It is a cross-sectional view of the light-emitting component 10 provided in Embodiment 1 of the present application; image 3 It is a top view of the light-emitting component 10 provided in Embodiment 1 of the present application. The light-emitting component 10 includes an epitaxial substrate 1, an N-type material layer 2 disposed on the epitaxial substrate 1, a light-emitting layer 3 disposed on the N-type material layer 2, and a light-emitting layer 3 disposed on the light-emitting layer 3. The P-type material layer 4, the passivation layer 5 covering the P-type material layer 4, the light-emitting layer 3 and the N-type material layer 2, and the anode pad 6 arranged on the passivation layer 5 and the cathode pad 7; specifically, the passivation layer 5 is provided with a first via hole 51 on the P-type material layer 4, and the passivation layer 5...

Embodiment 2

[0071] see Figure 6 , Figure 7, Embodiment 2 of the present application provides a light-emitting component 10a, including all the technical features of Embodiment 1, the difference is that the light-emitting component 10a in Embodiment 2 is further on the upper surface of the epitaxial substrate 1, along The epitaxial substrate 1 is surrounded by auxiliary grooves 11 , and the anode pad 6 and the cathode pad 7 extend into the auxiliary groove 11 . This can further make the anode pad 6 and the cathode pad 7 cover the surrounding surface of the epitaxial substrate 1, thereby increasing the coverage of the anode pad 6 and the cathode pad 7 on the light-emitting surface. layer 3, so as to further improve the chance of light being reflected to the epitaxial substrate 1 between the anode pad 6 and the cathode pad 7, and avoid the side-emitted light from adjacent two light-emitting components Mixed light appears between 10a.

[0072] Similarly, see Figure 7 , the anode pad 6 ...

Embodiment 3

[0078] see Figure 10 , Figure 11 , Embodiment 3 of the present application provides a light-emitting assembly 10b, including all the technical features of Embodiment 2, the difference is that the light-emitting assembly 10 in Embodiment 3 is further provided with a cutting recess in the auxiliary groove 11 The groove 12 , the anode pad 6 and the cathode pad 7 extend into the cutting groove 12 . This can further make the anode pad 6 and the cathode pad 7 cover the surrounding surface of the epitaxial substrate 1 and fill in the auxiliary groove 11 and the cutting groove 12, thereby increasing the The anode pad 6 and the cathode pad 7 are covered in the range of the light-emitting component 10b, thereby further increasing the chance of laterally emitted light being reflected between the anode pad 6 and the cathode pad 7 , avoid light mixing between two adjacent light-emitting components 10 .

[0079] Similarly, the anode pad 6 partially covers the three sides of the passiva...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com