Novel millimeter wave radio frequency coaxial connector and cable connecting method thereof

A radio frequency coaxial and connector technology, which is applied to the parts, connections, and two-part connection devices of the connecting device, can solve the problems of not meeting the performance index requirements of the cable assembly and the low frequency range of use, and achieve superior bending performance, The effect of ensuring stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

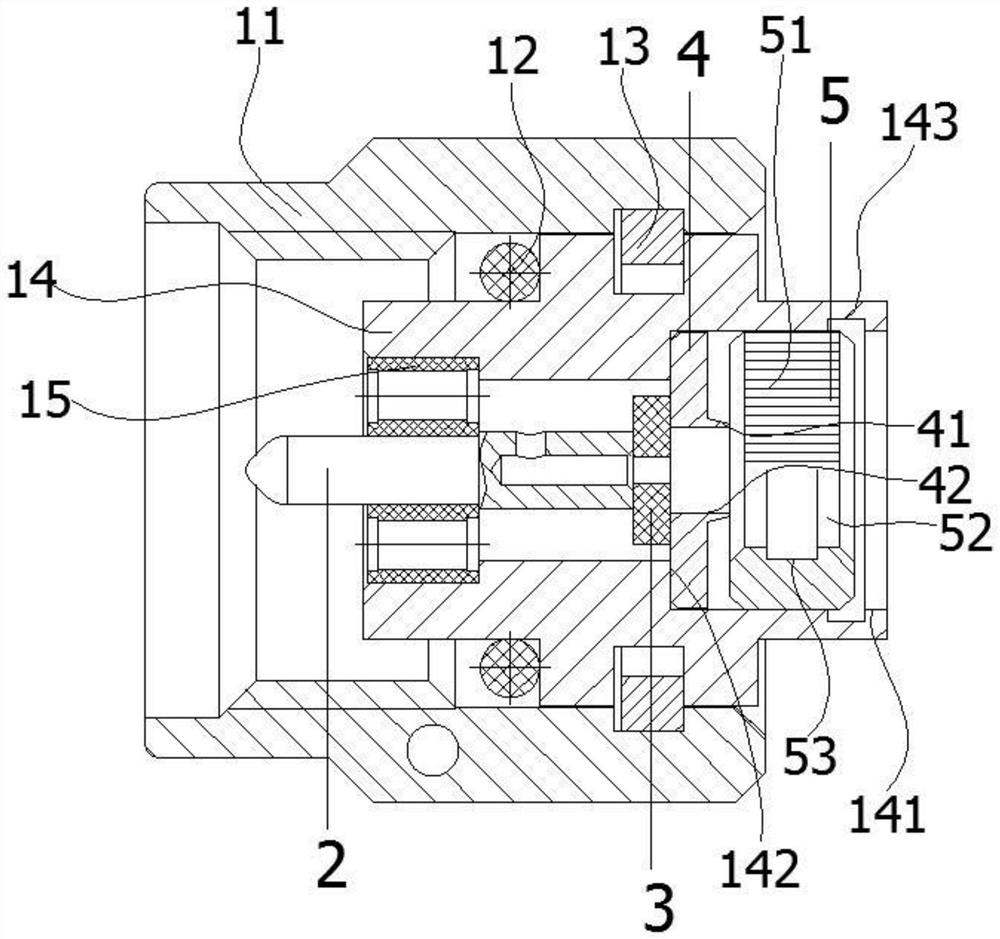

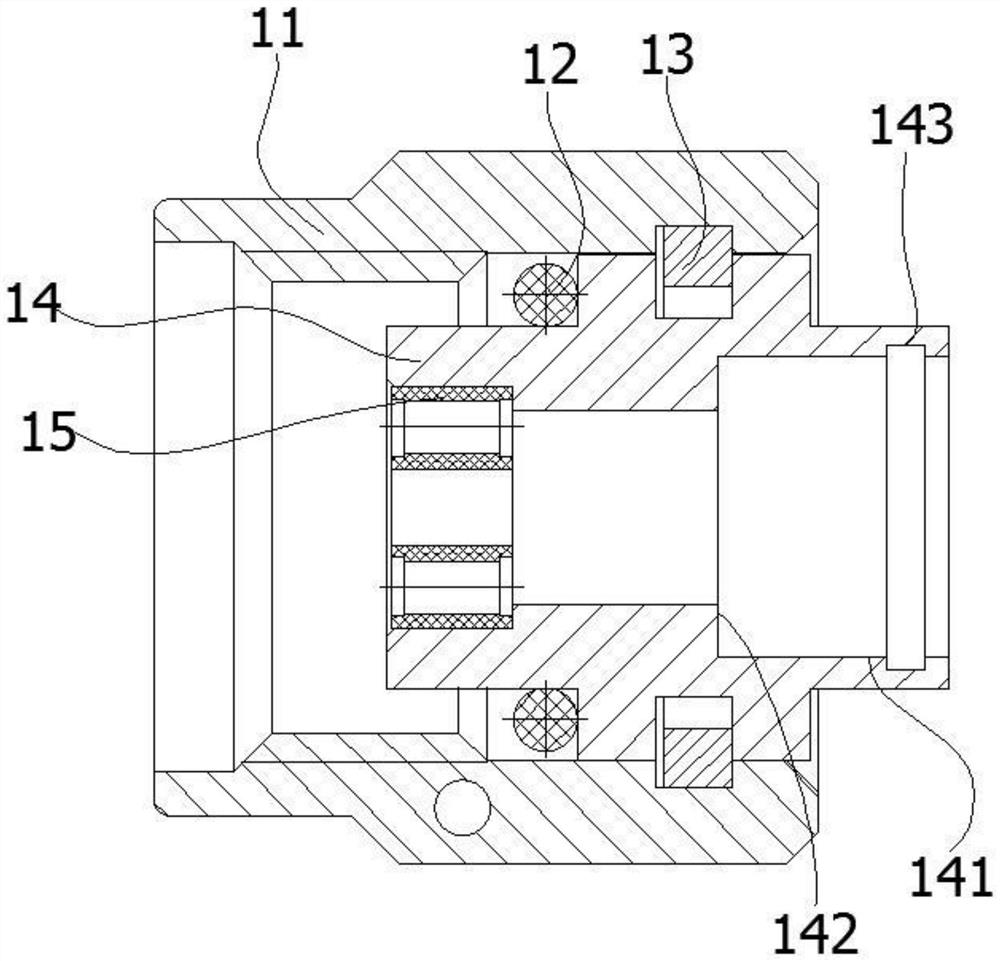

[0020] Such as Figure 1~Figure 5 As shown, a millimeter-wave radio frequency coaxial connector includes an outer conductor fitting, a pin contact 2, a dielectric gasket 3, a sleeve 4 and a bushing 5, and the outer conductor fitting includes a screw sleeve 11 assembled together , an O-ring 12, a retaining ring 13, an outer conductor 14 and a supporting medium 15, wherein the tail of the outer conductor 14 is provided with a stepped hole 141, a stepped surface 142 and a first annular groove 143 structure.

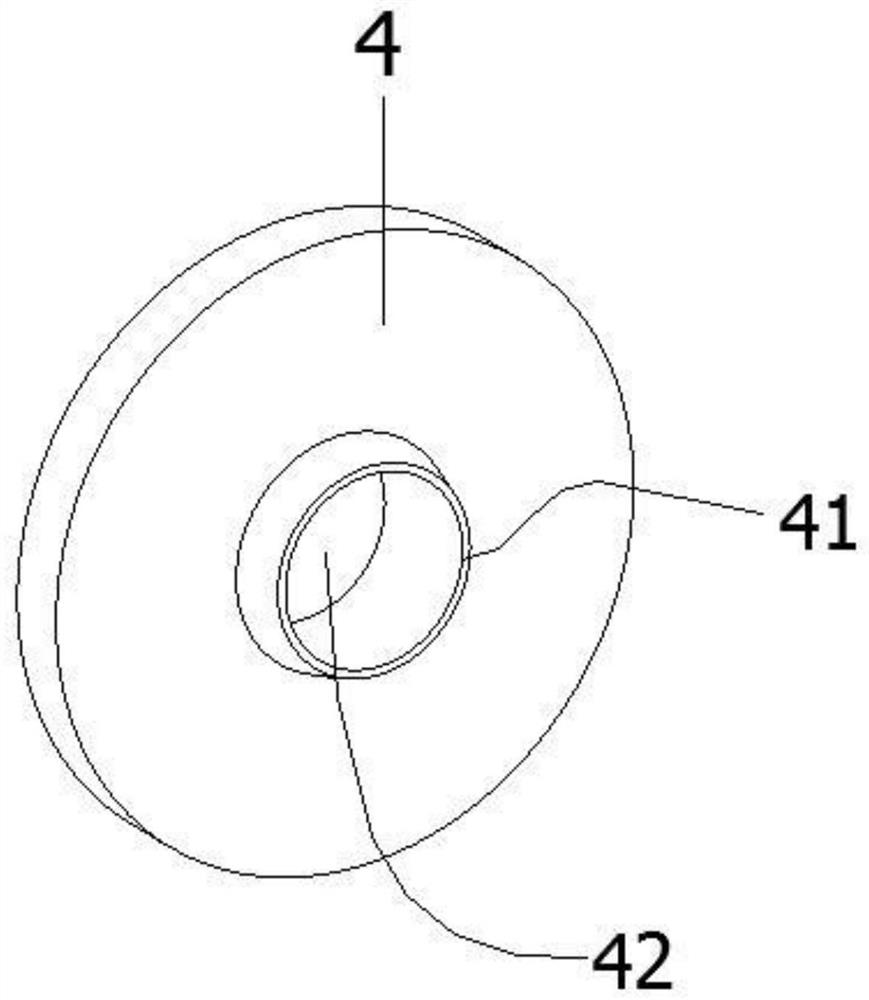

[0021] In this embodiment, one end of the outer conductor 14 is provided with a stepped hole 141, and the stepped hole 141 is provided with a stepped surface 142 and a first annular groove 143 for potting glue; the sleeve 4 includes a through hole 42, and the sleeve 4 One end face of the sleeve is provided with a barb 41, and the other end face fits on the stepped surface 142; the outer circumference of the sleeve 4 is in clearance fit with the stepped hole 141; the outer ci...

Embodiment 2

[0027] Based on the millimeter-wave radio frequency coaxial connector described in Embodiment 1, this embodiment provides a method for connecting cables using the millimeter-wave radio frequency coaxial connector described in Embodiment 1, including: passing the cable 6 through the sleeve 5 The threading hole 52, the outer sheath of the cable 6 fits with the threading hole 52; insert the barb 41 of the sleeve 4 between the insulating medium and the shielding layer 61 of the cable 6, and then install the sleeve 4 in the stepped hole of the outer conductor 14 Inside 141: the through hole 42 of the sleeve 4 is interference fit with the insulating medium of the cable 6, and the end face of the insulating medium of the cable 6 is flush with the end face of the sleeve 4 attached to the step surface 142, and is aligned with the step of the outer conductor 14 The surface 142 is in full contact; the bushing 5 is installed in the stepped hole 141 of the outer conductor 14: the outer circ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com