Processing technology of freeze-dried instant noodles

A processing technology and instant noodle technology, applied in the fields of food science, food preservation, application, etc., can solve the problems of short shelf life, loss of ingredients, denaturation, etc., and achieve good fresh noodles, soft and tough taste, stable product quality, and simple production process. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

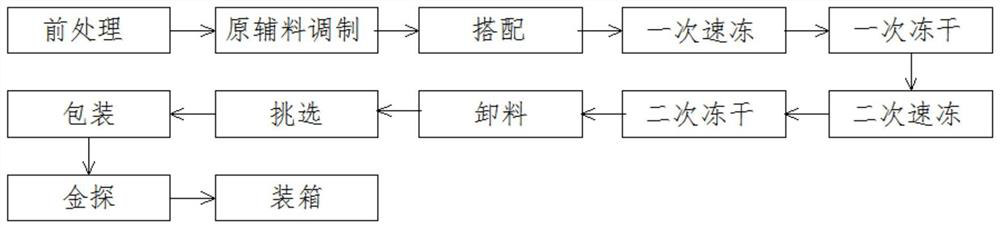

[0050] see figure 1 , the embodiment of the present invention provides a kind of processing technology of freeze-dried instant noodles, carries out cooking treatment to noodles, specifically comprises:

[0051] Step S11: pre-processing: cleaning, shaping, dicing the auxiliary materials including meat products, seafood products, and vegetable products, and making dough into noodles;

[0052] Step S:12: Preparation of raw and auxiliary materials: processing the raw noodles and auxiliary materials separately, including cooking and seasoning;

[0053] Step S13: Matching: mix the noodle raw materials and various auxiliary materials according to the ratio;

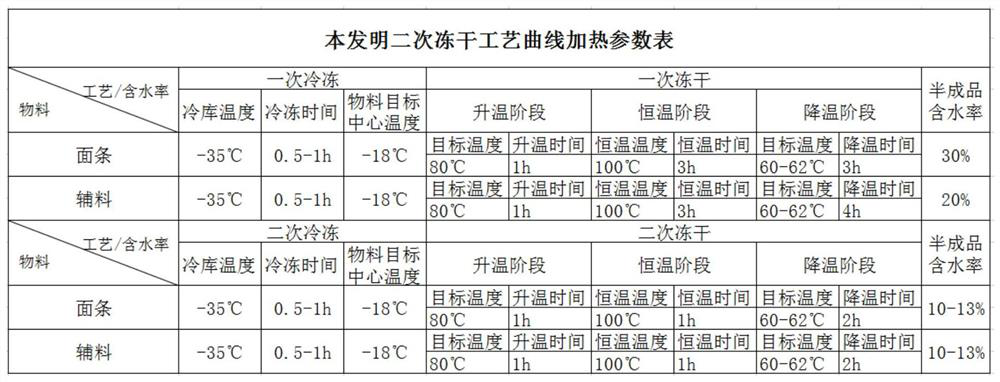

[0054] Step S20: One-time quick freezing: the noodles and auxiliary materials are separately quick-frozen, and frozen in a -35° quick-freezer for 30-60 minutes, so that the central temperature of the noodles and auxiliary materials reaches below -18°;

[0055] Step S30: Primary freeze-drying: transfer the quick-frozen noodles ...

Embodiment 2

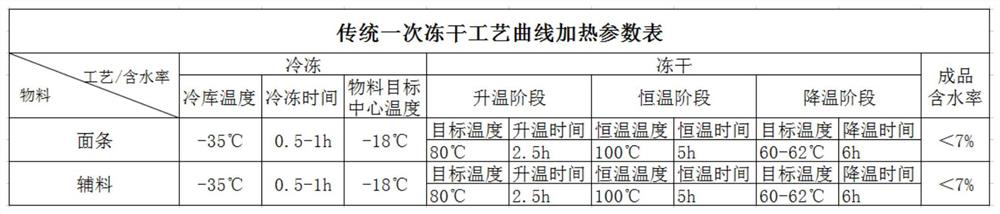

[0080] As a technical comparison of the necessity of the secondary freeze-drying process, this embodiment adopts the traditional primary mixed freeze-drying process, and the specific steps include:

[0081] Step S11: pre-processing: cleaning, shaping, dicing the auxiliary materials including meat products, seafood products, and vegetable products, and making dough into noodles;

[0082] Step S:12: Preparation of raw and auxiliary materials: processing the raw noodles and auxiliary materials separately, including cooking and seasoning;

[0083] Step S13: Matching: mix the noodle raw materials and various auxiliary materials according to the ratio;

[0084] Step S20: One-time quick freezing: the noodles and auxiliary materials are mixed and quick-frozen, and frozen in a -35° quick-freezer for 30-60 minutes, so that the central temperature of the noodles and auxiliary materials reaches below -18°;

[0085] Step S30: Primary freeze-drying: transfer the quick-frozen noodles and au...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com