A large flow compressed air foam fire truck

A technology for compressed air foam and fire trucks, applied in fire rescue and other directions, can solve the problems of insufficient foam liquid and water, dependence on the accuracy of proportion control, affecting the proportion of foam liquid, etc., to achieve uniform proportion and increase the utilization rate of raw materials , the effect of increasing the contact area

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach

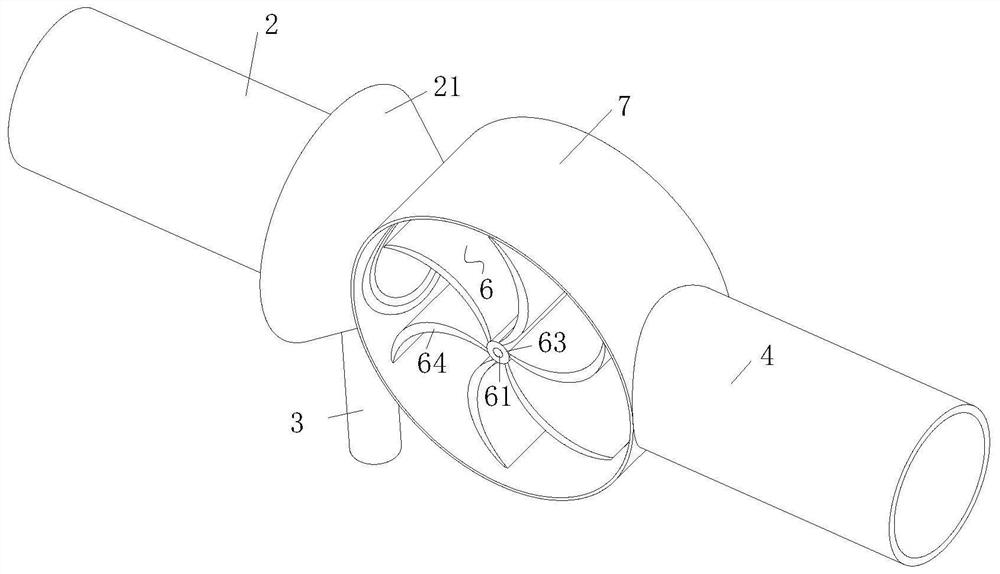

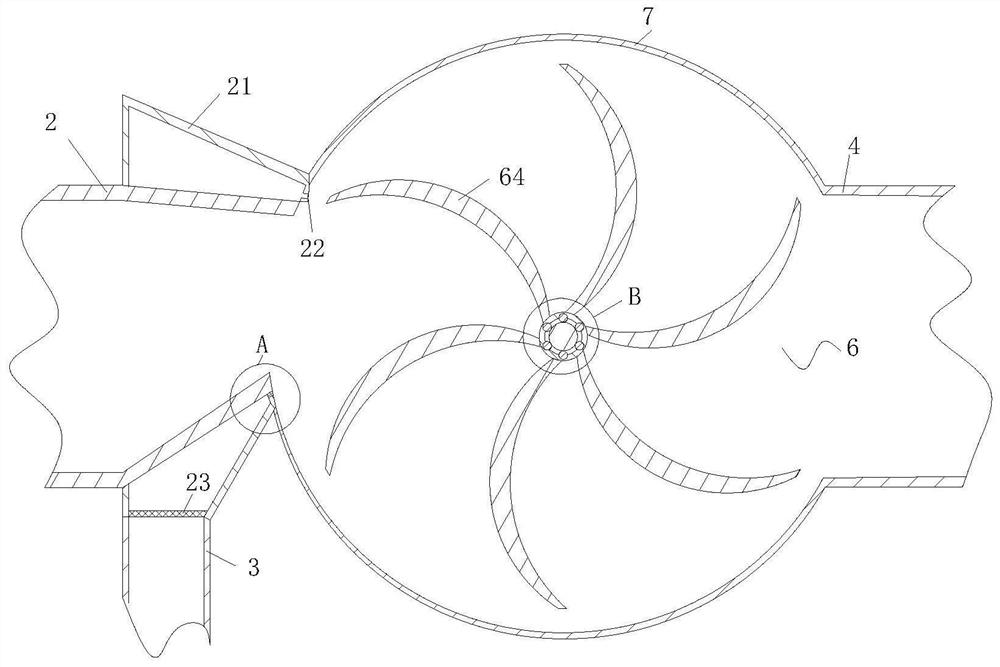

[0044] As an embodiment of the present invention, the cross-sectional shape of the blade 64 is arc-shaped;

[0045] When working, water is conveyed through the water inlet pipe 2, and then hits the surface of the blade 64. The cross-sectional shape of the blade 64 is arc-shaped so that on the one hand, the blade 64 can withstand greater impact and prolong the service life of the blade 64. After the water hits the surface of the curved blade 64, it can flow along the curved plate, and then flow between the blade 64 and the blade 64. At this time, the water can mix the foam liquid on the surface of the blade 64 together and roll;

[0046] In the present invention, the cross-sectional shape of the vane 64 of the spoiler 6 is set to be arc-shaped, and then cooperate with the outlet of the water inlet pipe 2 to align with the vane 64, so as to achieve the purpose that water can flow along the vane 64 after hitting the vane 64, Furthermore, more water can flow between the blades 64 ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com