Gas burner capable of producing ionized gas flame

A gas burner and burner technology, which is applied in the directions of gas fuel burners, burners, combustion types, etc., to achieve the effects of uniform proportioning, reduction of exhaust emissions, and uniform splitting of gas molecules

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

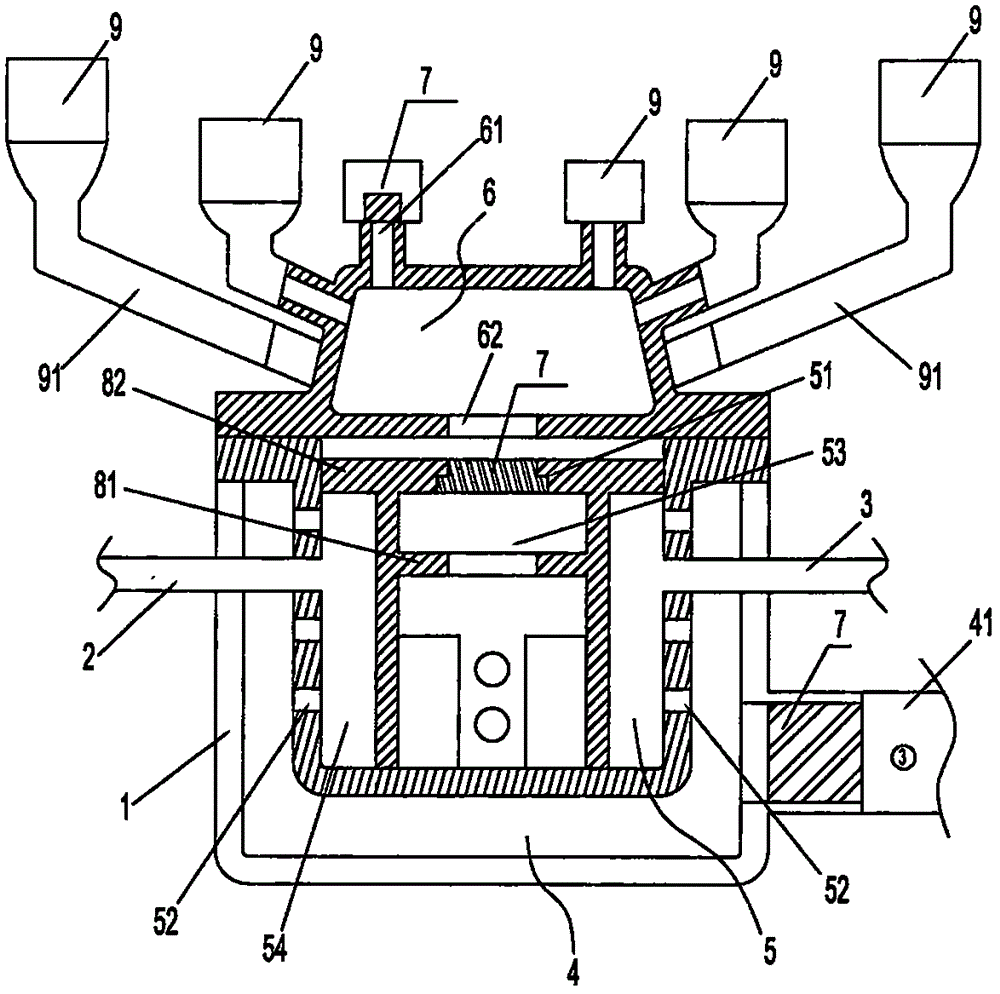

[0035] Such as Figure 1 to Figure 3 A gas burner that can generate ionized gas flames is shown, including a burner body 1, an air input channel 2, and a gas input channel 3, and the burner body 1 includes a fresh air chamber 4 and an air mixing chamber 5 and the confluence chamber 6, the air mixing chamber 5 is arranged in the fresh air chamber 4, and there is a gap 7 acting on the air channel between the air mixing chamber 5 and the fresh air chamber 4, and the confluence chamber 6 is arranged in the air mixing chamber 5 The upper part communicates with the gas mixing chamber 5 to form a sealed burner body 1; the air input channel 2 and the gas input channel 3 are arranged in the middle of the gas mixing chamber 5, and the fresh air inlet 41, The air mixing outlet 51 of the air mixing chamber 5 and the air outlet 61 of the confluence chamber 6 are respectively provided with a swirl compressor 7 .

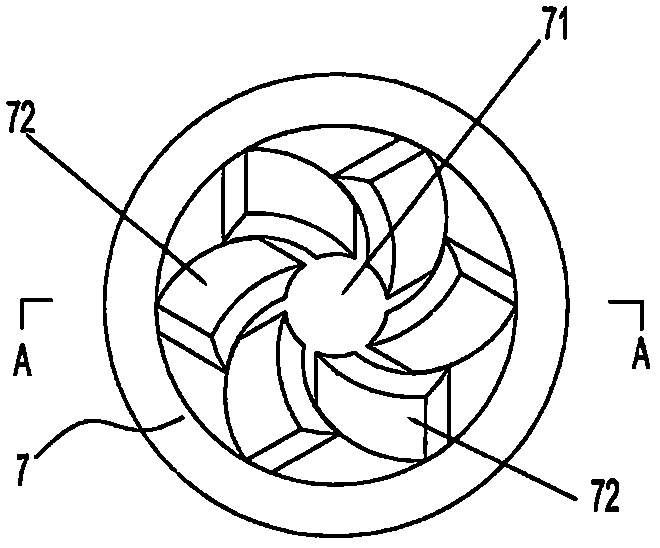

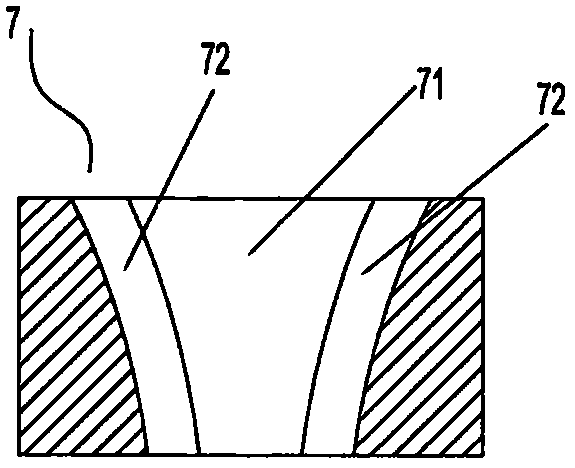

[0036] Further, the swirl compressor 7 is composed of a ventilation part wit...

Embodiment 2

[0041] The technical characteristics of this embodiment are: as Figure 4 As shown, a plurality of second air inlet holes 55 are also provided on the catalytic converter 8, and the second air inlet holes 55 correspond to the first air inlet holes 52, forming a straight passage of gas. The confluence inlet 62 of the confluence chamber 6 is a through hole located directly above the gas mixing outlet 51 of the gas mixing chamber 5, and a certain distance is reserved between the confluence inlet 62 and the gas mixing outlet 51, so that the connection between the confluence chamber 6 and the catalytic converter 8 An inner chamber 85 is formed between the upper cover plates 82 , and a confluence inlet 86 is provided at the confluence inlet 62 . The size of the confluence inlet 86 corresponds to the size of the inner chamber 53 of the gas mixing chamber 5 . The upper cover plate 82 of the catalytic converter 8 is located above the air gap 54 and is provided with a plurality of catal...

Embodiment 3

[0043] The technical characteristics of this embodiment are: as Figure 5 As shown, the confluence chamber 6 is provided with an installation base plate 63 corresponding to the gas mixing chamber 5, and the confluence chamber 6 is installed on the fresh air chamber 4 and the gas mixing chamber 5 through the installation base plate 63, in a vertical distribution structure, so that The fresh air chamber 4, the mixed air chamber 5 and the confluence chamber 6 form a burner housing in a closed mode, and the confluence inlet 86 is arranged below the installation base plate 63, and one or more convection currents are provided on the installation base plate 63. The hole 631, the convection hole 631 is located on the outside of the confluence inlet 86 corresponding to the convection flow 821 of the catalytic converter, and the rest is the same as the above embodiment.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com