Bilateral simultaneous friction stir welding process parameter optimization method

A process parameter optimization, friction stir welding technology, applied in manufacturing tools, welding equipment, non-electric welding equipment and other directions, can solve the problems of local optimization of numerical methods, complex process, insufficient theoretical support, etc., to achieve convenient and efficient process parameter optimization, Simple to use effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0056] In order to further understand the invention content, characteristics and effects of the present invention, the following embodiments are enumerated hereby, and detailed descriptions are as follows in conjunction with the accompanying drawings:

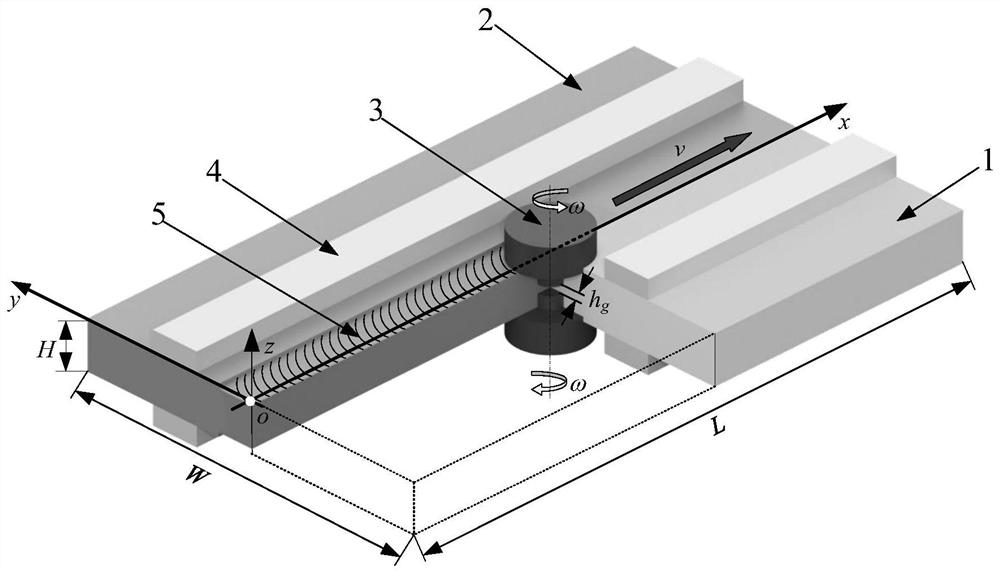

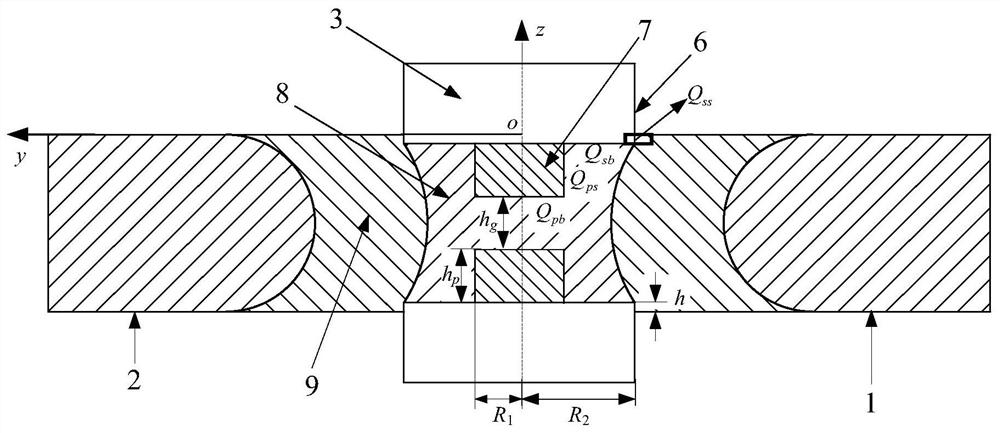

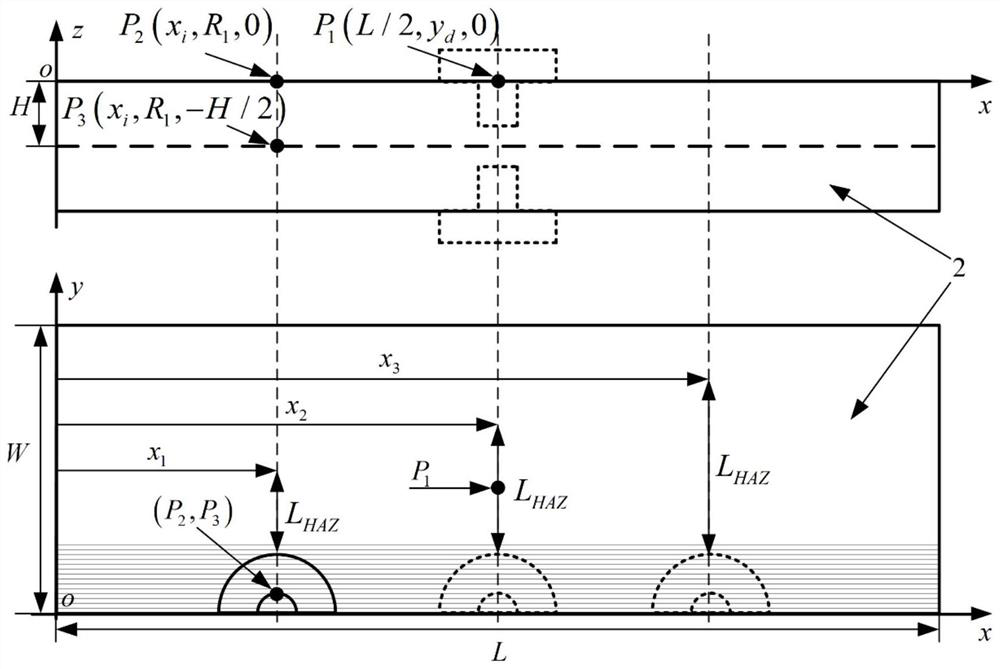

[0057] See Figure 1 to Figure 4 , a double-sided simultaneous friction stir welding process parameter optimization method, based on the heat production mechanism of the friction stir welding process, the Fourier heat transfer law and the law of energy conservation, the heat production model of the double-sided simultaneous friction stir welding is established, and the process to be optimized is determined Parameters, taking the minimum input energy per unit length of welding as the objective function, setting constraints according to the welding process, and establishing an optimization model; using the sequential quadratic programming algorithm to solve the optimization model, and obtaining the optimal process parameter values...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com