A high-quality carbon black combustion production device

A production device and high-quality technology, applied in the direction of fibrous fillers, etc., can solve problems such as uneven preheating and insufficient combustion, and achieve the effect of ensuring the quality of preheating and high combustion quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

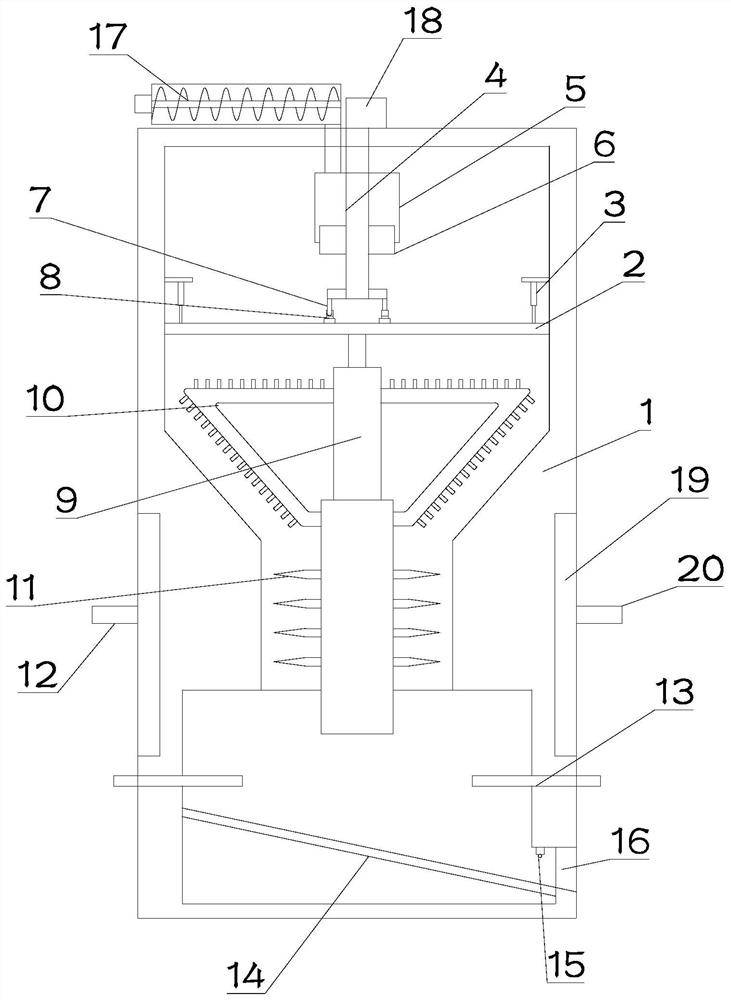

[0025] see figure 1 , in Embodiment 1 of the present invention, a structural diagram of a high-quality carbon black combustion production device provided for the embodiment of the present invention, including: a device main body 1, the interior of the device main body 1 is divided into material distribution chambers from top to bottom , combustion chamber and cooling chamber;

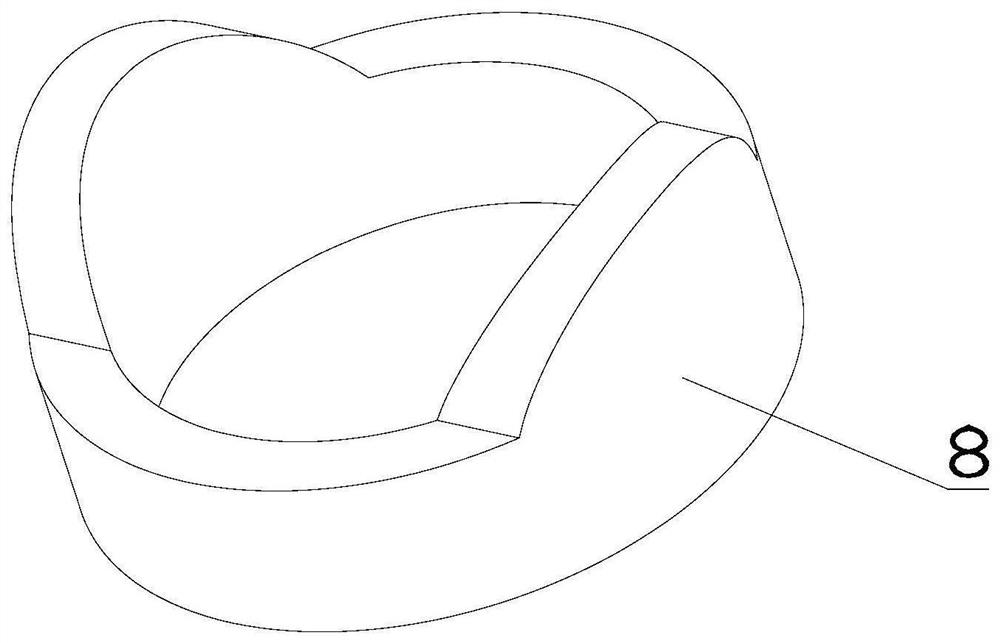

[0026] Wherein, the distributing chamber is provided with a distributing assembly and a dispersing net 2 that is set by jumping; the bottom of the distributing net 2 is fixedly installed with 9, and the outlet at the bottom of the exhaust tube 9 is set in the combustion chamber; the exhaust A plurality of branch connecting cylinders 10 are arranged in an array on the outer side of the cylinder 9; a feeding port is provided on the distribution assembly;

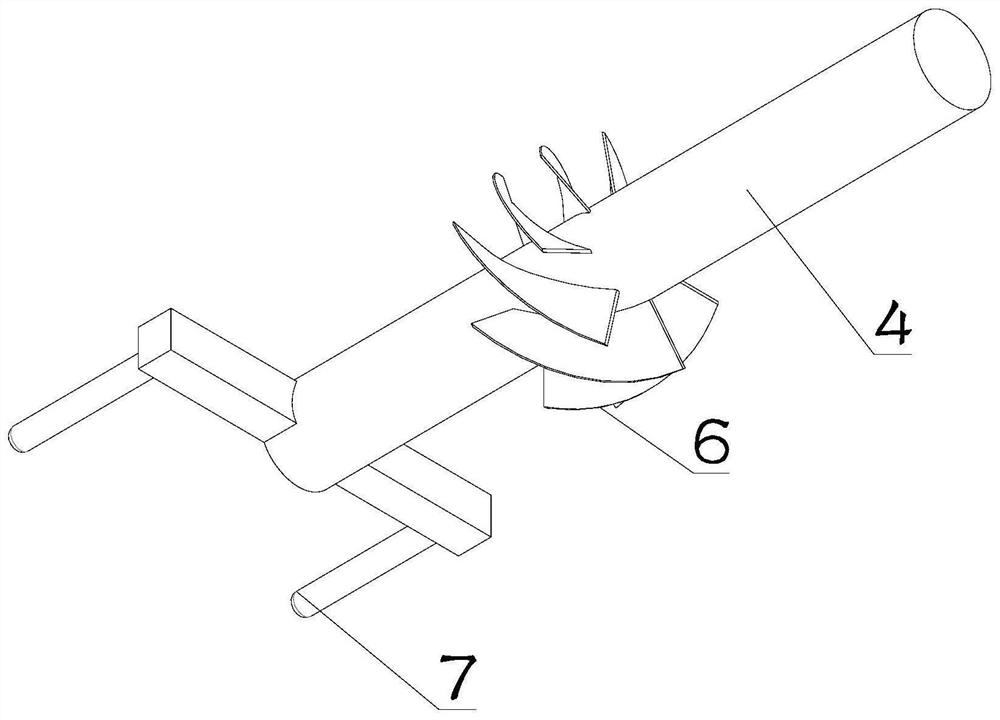

[0027] The material distributing assembly includes a uniform material sleeve 5 fixedly installed inside the main body 1 of the device, a rotating shaf...

Embodiment 2

[0031] see Figure 1~3 The main difference between this embodiment 2 and embodiment 1 is that in order to drive the rotating shaft 4 to rotate, a driving mechanism is also provided on the device main body 1, and the driving mechanism includes a rotating motor 18 fixedly installed on the device main body 1, so The rotating motor 18 is transmission connected with the rotating shaft 4, and the rotating motor 18 can be connected with it through a gear or a chain.

[0032] As a preferred embodiment of the present invention, in order to realize the continuous input of raw materials to the inside of the uniform material sleeve 5, the main body 1 of the device is also provided with an auger 17, and the output end of the auger 17 is connected to the material uniform sleeve. 5 internal connections. In this way, the auger 17 can continuously provide raw materials for the uniform material sleeve 5 .

[0033] The outer side of the branch connecting cylinder 10 is provided with a pluralit...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com