Dry-method simultaneous desulfurization and dechlorination system and method for blast furnace gas

A technology of blast furnace gas and coal gas, which is applied in the field of blast furnace gas dry simultaneous desulfurization and dechlorination system, can solve the problems of increasing investment in blast furnace gas deacidification and occupying industrial land, and achieves the effects of cost saving, industrial land saving and investment saving

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

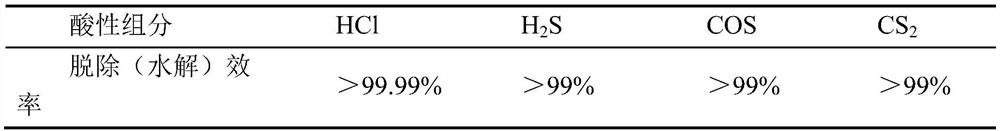

Examples

Embodiment Construction

[0018] BRIEF DESCRIPTION OF THE PREFERRED DESCRIPTION OF THE PREFERRED DESCRIPTION OF THE PREFERRED EMBODIMENTS The present invention can be embodied in many different forms of embodiments, and the scope of the invention is not limited to the embodiments mentioned in the article.

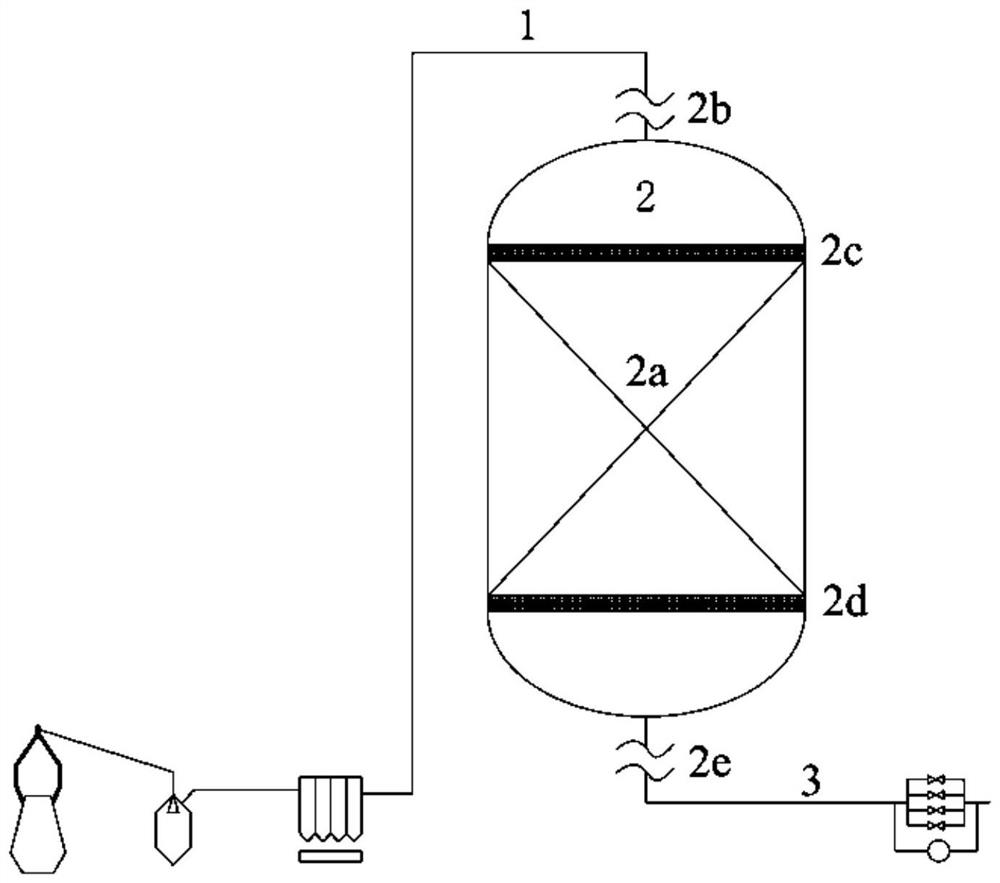

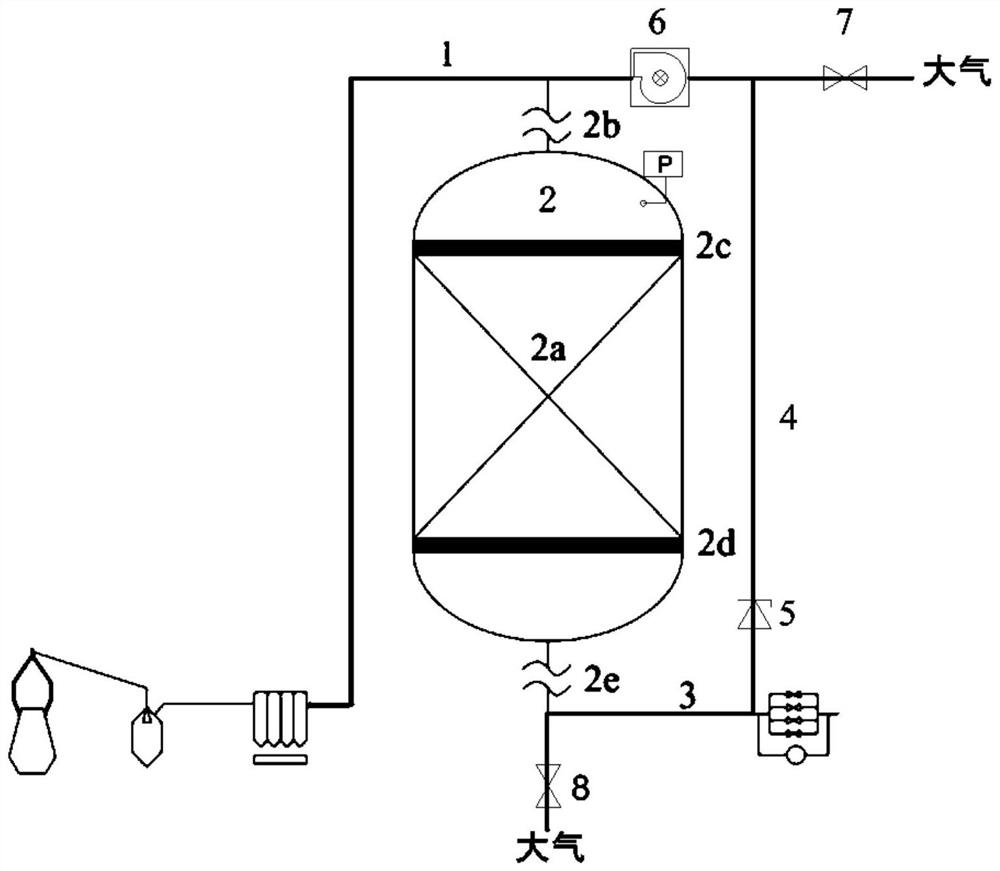

[0019] The blast furnace gas according to the present invention a dry dechlorination simultaneous desulfurization system See figure 1 .

[0020] The system includes a dedusting apparatus blast clean gas feeding subsystem, subsystem synergistic desulfurization dechlorination tower, cooperative subsystem replacement deacidifying agent; wherein

[0021] After the blast furnace dust net gas feeding subsystem: Crude Gas blast furnace dust generated through gravity, after the clean gas through the filter bag 1 into the gas pipes 2 dechlorination synergistic desulfurization tower.

[0022] Dechlorination synergistic desulfurization tower deacidification subsystems: subsystem connected after the gas pipeline 1,...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com