Tunnel hard rock non-blasting excavation method

A non-blasting, hard rock technology, applied in the direction of tunnels, earthwork drilling, mining equipment, etc., can solve the problems that the construction efficiency is greatly affected, the number of drilling holes is large, and the construction efficiency is affected, achieving significant technical advantages and overcoming the blasting effect , High excavation efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

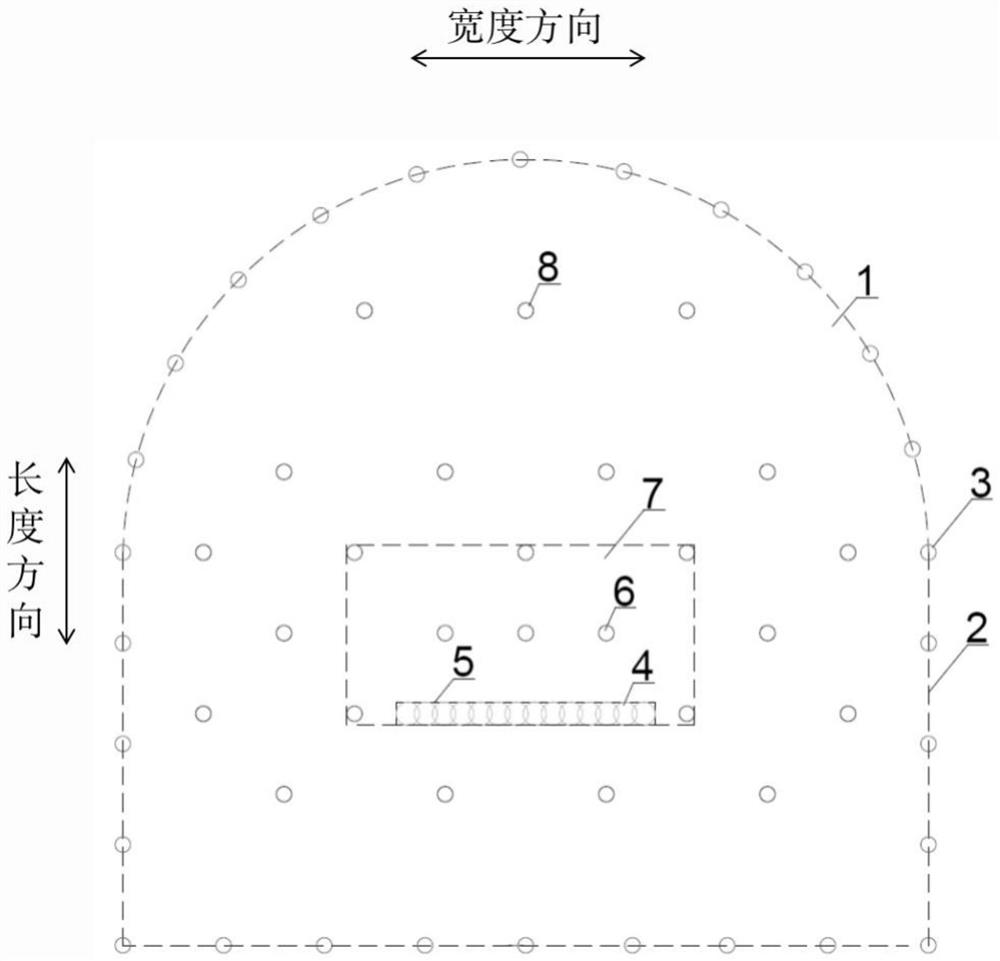

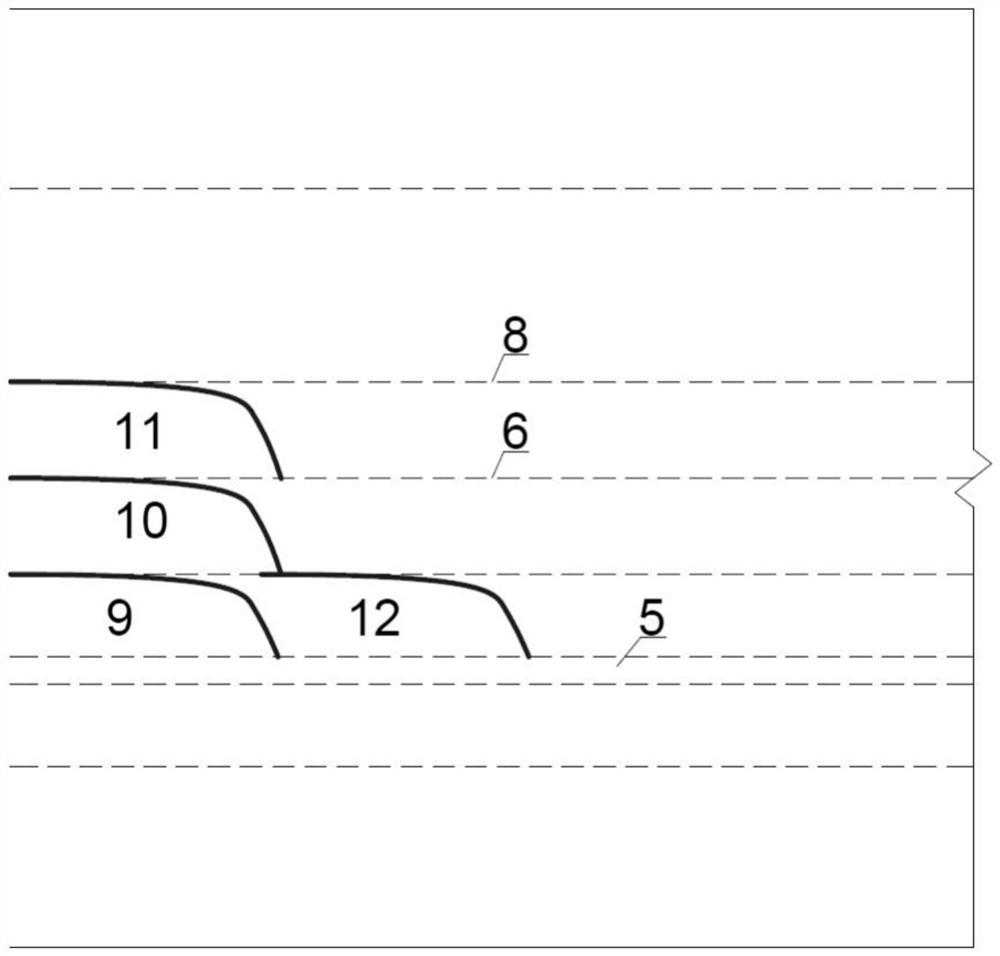

[0024] A specific embodiment of the tunnel hard rock non-burst excavation method according to the present invention will be described in detail below with reference to the accompanying drawings.

[0025] like figure 1 As shown, the hard rock section of a project tunnel is 3.9m, the height is 3.9m, and the section is 13.58m. 2 Construction using the technical solution of the present invention, the specific steps are as follows:

[0026] (1) In the palm shedral line 2 and the tunnel axis, the outer interpolation angle is formed, and the contour hole 3 is formed, thereby determining the range of tunnel excavation, in the present embodiment, the contour hole 3 pore size is 76mm, the borehole spacing is 0.5m, and the drilling is 4m.

[0027] (2) According to the range of excavation, choose figure 1 The position of the last row is the position of the drilling into the tank, and the expansion hole 6 is drilled near the position. In the present embodiment, the expansion hole 6 has a hole ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Depth | aaaaa | aaaaa |

| Diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com