Water pressure weighing and drying method for gas cylinder

A gas cylinder and water pressure technology, applied in drying, dryer, weighing and other directions, to achieve the effect of shortening drying time, lowering production cost and safety risk, and improving drying process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

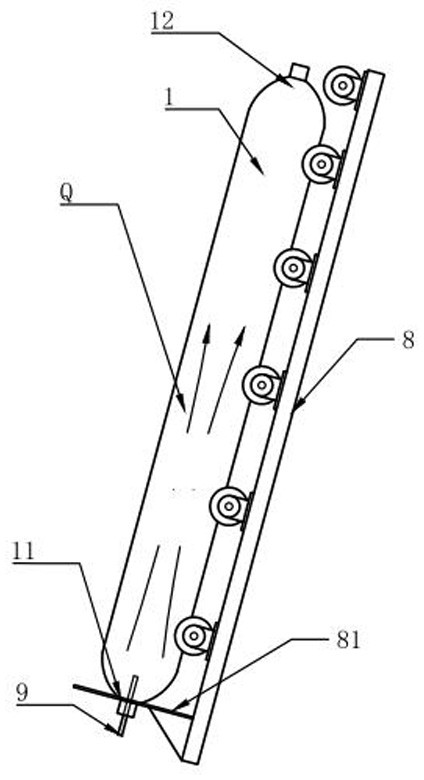

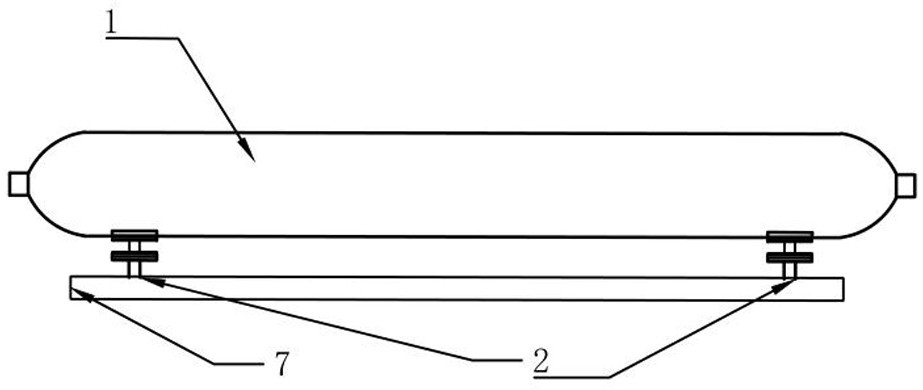

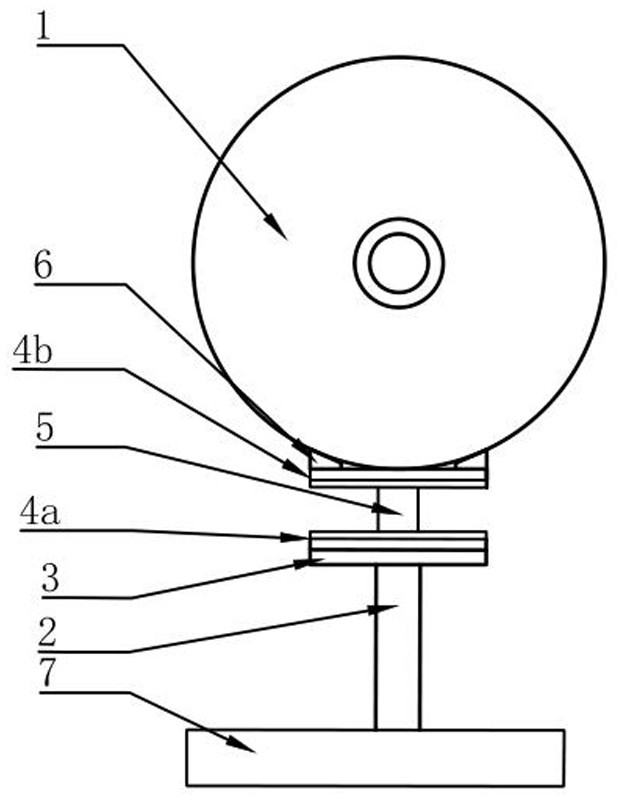

[0018] The specific implementation of the present invention will be described in further detail below in conjunction with the accompanying drawings of the embodiments, so as to make the technical solution of the present invention easier to understand and grasp, so as to define the protection scope of the present invention more clearly.

[0019] The designer of the present invention aims at many deficiencies in the prior art in the single function of large steel high-pressure gas cylinders in hydraulic pressure detection and the unsatisfactory drying effect after measurement, and innovatively proposes a water pressure weighing and drying method for gas cylinders , to provide a more complete technical solution for the large-scale production and quality inspection of industrial high-pressure gas cylinders.

[0020] Starting from the existing technology, after the high-pressure gas cylinder is produced, it is necessary to use the hydraulic external testing machine, the pouring dryi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com