Preparation method for improving flavor of low-sodium salt roasted chicken

A production method and technology for salt-baked chicken are applied in the functions of food ingredients, food ingredients as substitutes, food ingredients as coating agents, etc. Improve the effect of tender meat and rich aroma

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

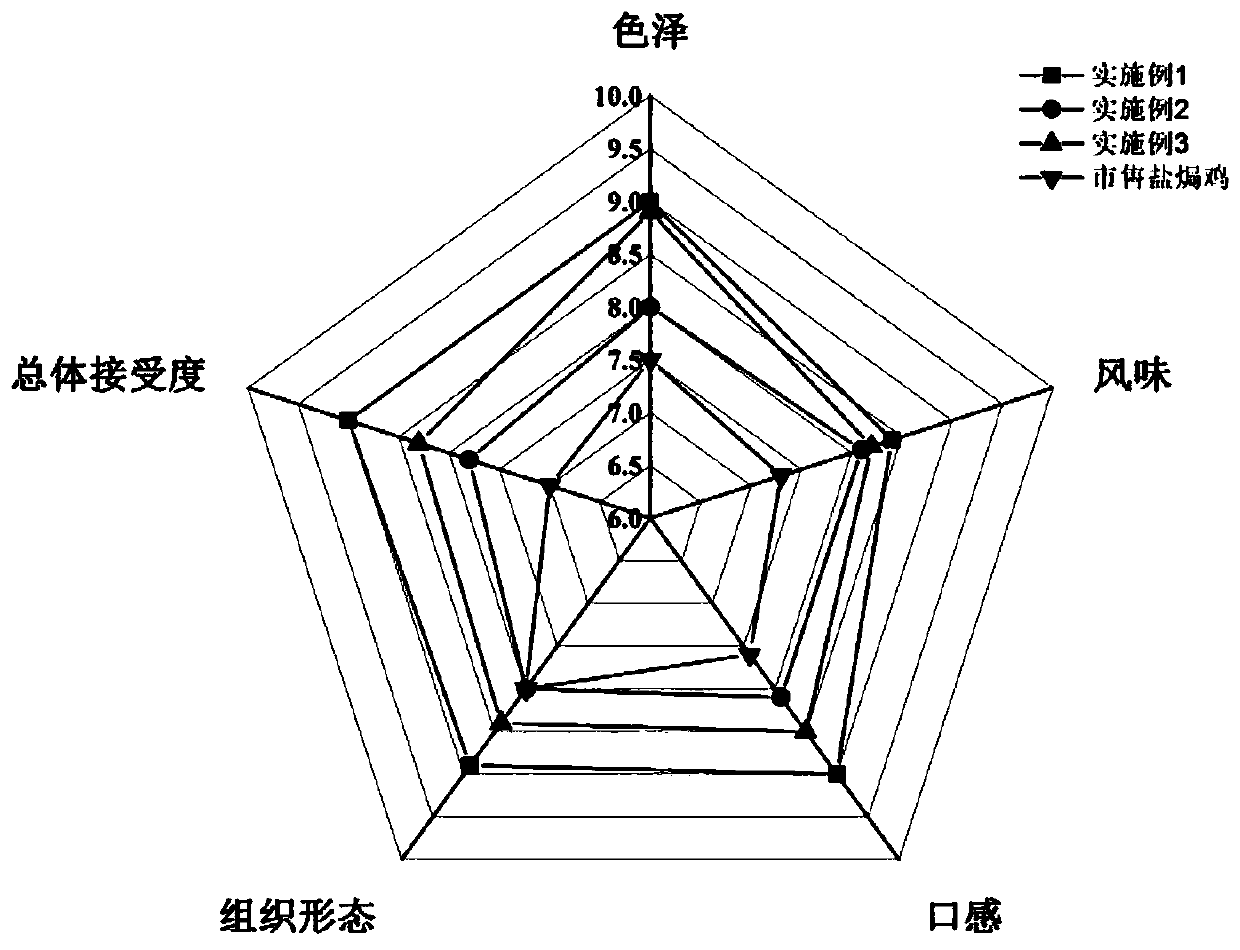

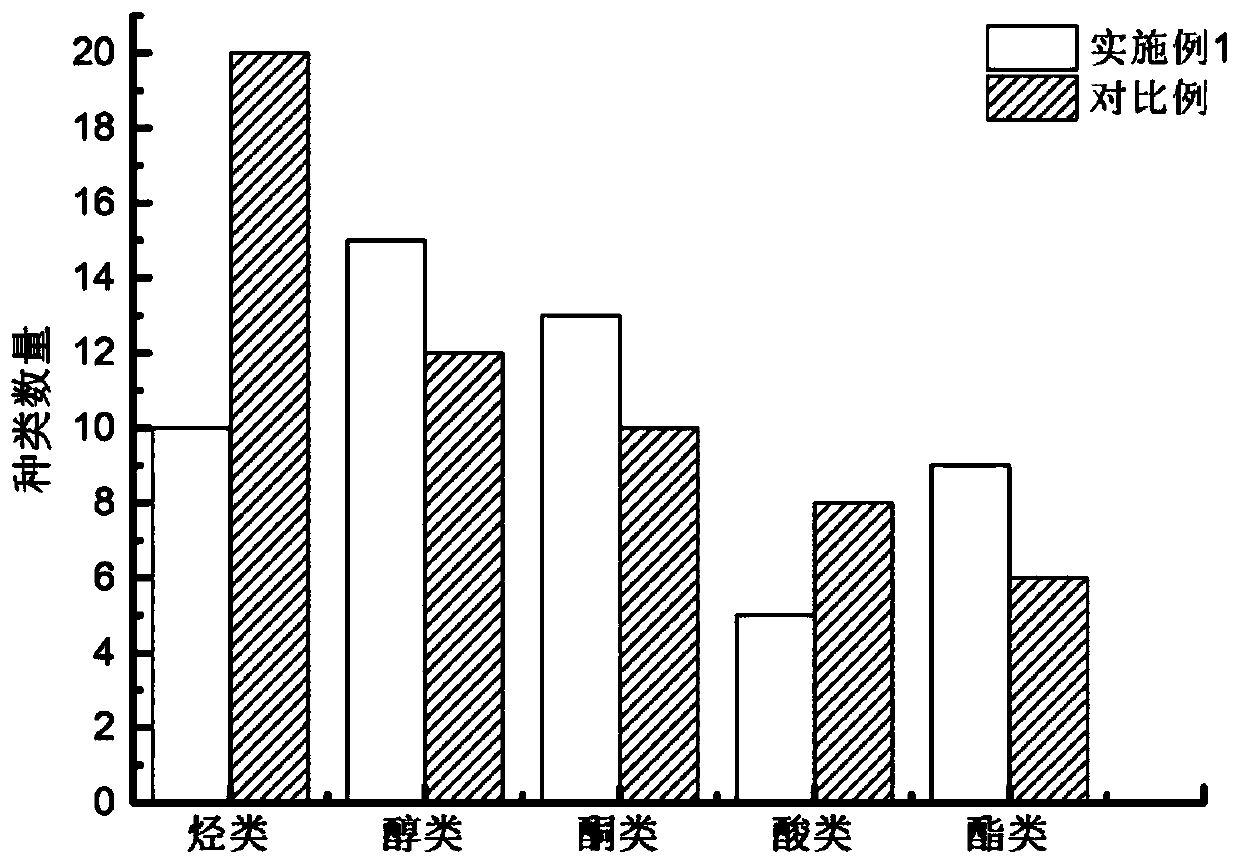

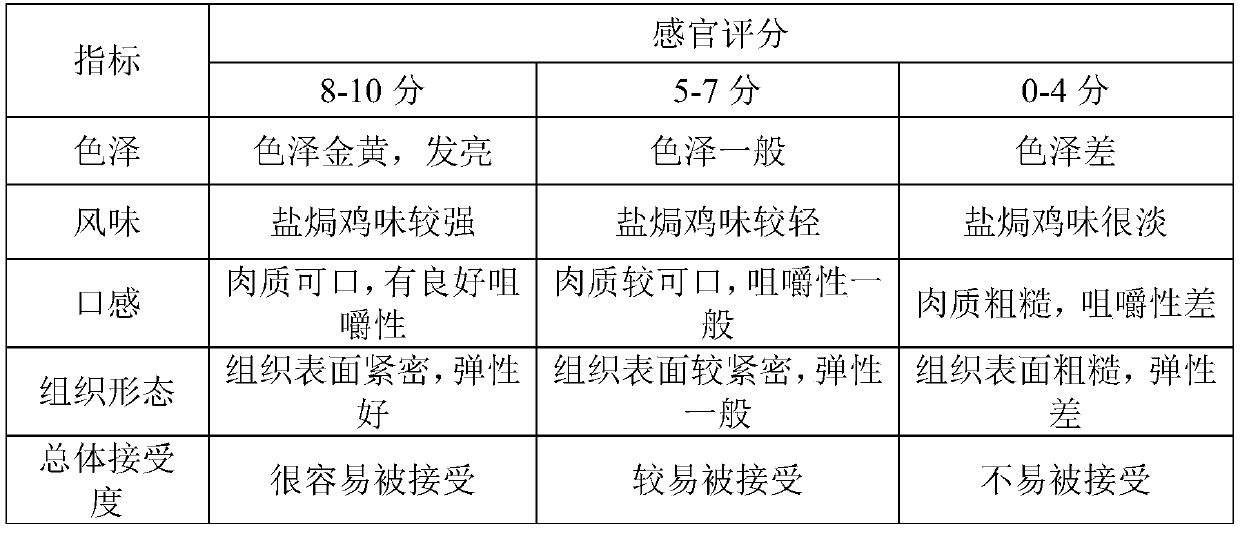

Embodiment 1

[0029] 1. Raw material pretreatment: After removing the viscera of live chickens, clean them with cold water and drain the surface water.

[0030] 2. Preparation of pickling liquid: prepare 2.5% pickling liquid, the weight components of which are 11 parts of salt, 6 parts of potassium chloride, 3 parts of disodium guanylate, 1 part of k-carrageenan, and 0.2 of L-malic acid 2 parts, sand ginger powder 2 parts, ginger powder 1 part; the remainder is water, mix well to obtain the pickling liquid, the pickling liquid is pre-cooled to a temperature of 4°C and set aside.

[0031] 3. Marinating treatment: immerse the chicken in the prepared marinating liquid, marinate and knead in a vacuum tumbler with a vacuum of 0.1MPa for 30 minutes, let it stand for 15 minutes, and knead twice. Set the speed to 1r / min, and control the marinating temperature at 4°C. Let stand and marinate for 30 minutes.

[0032] 4. Air-drying treatment: Adopt gradient cold air drying. Place the marinated chicken in a...

Embodiment 2

[0035] 1. Raw material pretreatment: After removing the viscera of live chickens, clean them with cold water and drain the surface water.

[0036] 2. Preparation of pickling liquid: prepare 2.5% pickling liquid, the weight components of which are 15 parts of salt, 8 parts of potassium chloride, 4 parts of disodium guanylate, 1 part of k-carrageenan, and 0.2 of L-malic acid 2 parts, sand ginger powder 2 parts, ginger powder 1 part; the remainder is water, mix evenly to obtain the pickling liquid, the pickling liquid is pre-cooled to a temperature of 4°C and set aside.

[0037] 3. Marinating treatment: immerse the chicken in the prepared marinating liquid, place it in a vacuum tumbler with a vacuum of 0.1MPa, marinate and knead for 30 minutes, stand for 15 minutes, and knead for 3 times. Set the speed to 1r / min, and control the marinating temperature at 4°C. Let stand and marinate for 30 minutes.

[0038] 4. Air-drying treatment: Adopt gradient cold air drying. Place the marinated c...

Embodiment 3

[0041] 1. Raw material pretreatment: After removing the viscera of live chickens, clean them with cold water and drain the surface water.

[0042] 2. Preparation of pickling liquid: prepare 2.5% pickling liquid, the weight components of which are 9 parts of salt, 7 parts of potassium chloride, 4 parts of disodium guanylate, 2 parts of k-carrageenan, and 0.3 of L-malic acid 2 parts, sand ginger powder 2 parts, ginger powder 2 parts; the remainder is water, mix well to obtain the pickling liquid, the pickling liquid is pre-cooled to a temperature of 4°C and set aside.

[0043] 3. Marinating treatment: immerse the chicken in the prepared marinating liquid, marinate and knead in a vacuum tumbler with a vacuum of 0.1MPa for 30 minutes, let it stand for 15 minutes, and knead twice. Set the speed to 1r / min, and control the marinating temperature at 4°C. Let stand and marinate for 30 minutes.

[0044] 4. Air-drying treatment: Adopt gradient cold air drying. Place the marinated chicken in ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com