Dust removal and collection method for lignite drying system

A drying system and lignite technology, applied in the field of coal chemical industry, can solve the problems of high consumption of raw materials, pollute the environment, difficult to recycle, etc., and achieve the effect of reducing environmental pollution and high recycling rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

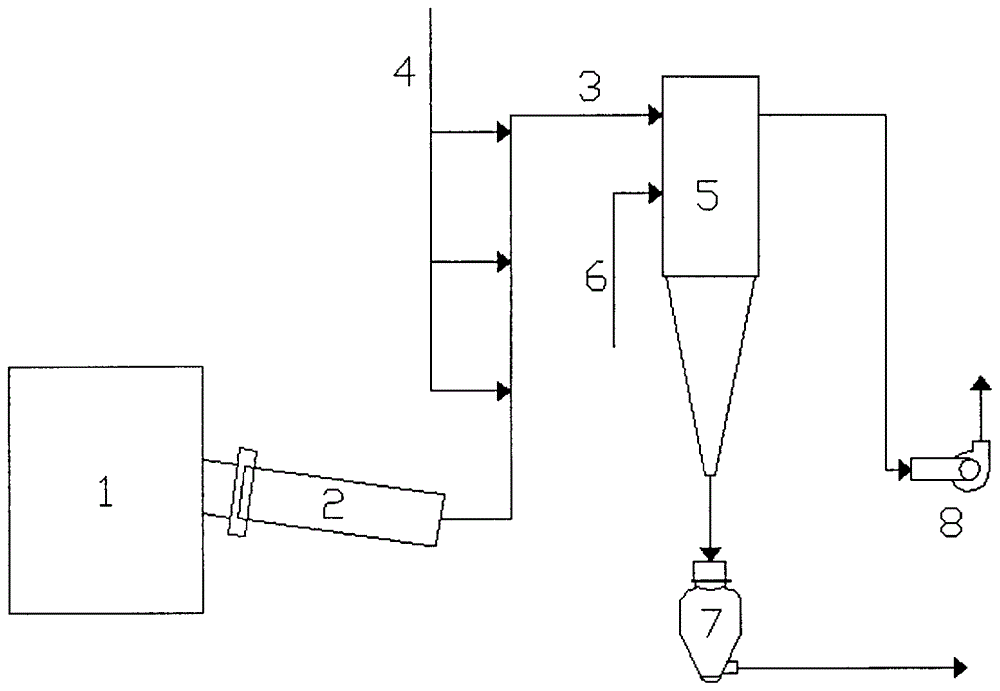

[0010] from figure 1 It can be seen that the mixed heating flue gas of the lignite drying system in this embodiment comes from the combustion furnace 1, is sucked into the drum dryer 2 by the induced draft fan 8, and contacts the raw material lignite to dry it. Coal powder is entrained in the low-temperature flue gas after the lignite is dried, and is recovered through the bag filter 5 . The clean flue gas passing through the bag is discharged through the chimney, and the warehouse pump 7 is installed at the lower part of the bag filter 5 to transport the collected pulverized coal with N2 and isolate it from the air. Wherein, the branch pipe of the nitrogen blowing pipe 4 is inserted into the air-inducing flue 3 every 5 meters, and the coal powder accumulated at the bottom of the air-inducing flue 3 is blown up, and enters the bag filter 5 together with the flue gas. The fire-fighting nitrogen pipe 6 is connected to the bag filter 5, and when the vehicle is parked, N2 is blow...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com