A kind of auxiliary system and method for hole detection intelligent detection of gas turbine engine

A gas turbine and auxiliary system technology, applied in computer parts, image analysis, instruments, etc., can solve problems such as missed and false detections, hidden dangers of aircraft flight safety, increased labor costs, etc., to reduce missed detections and meet remote Multiple people work together to achieve the effect of real-time data transmission

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

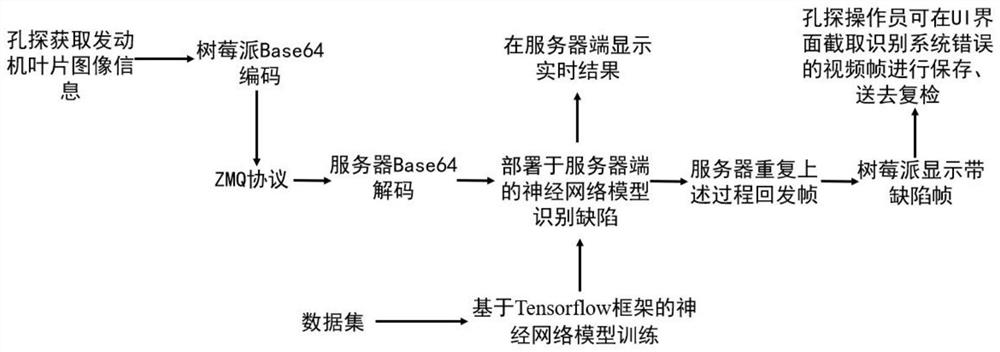

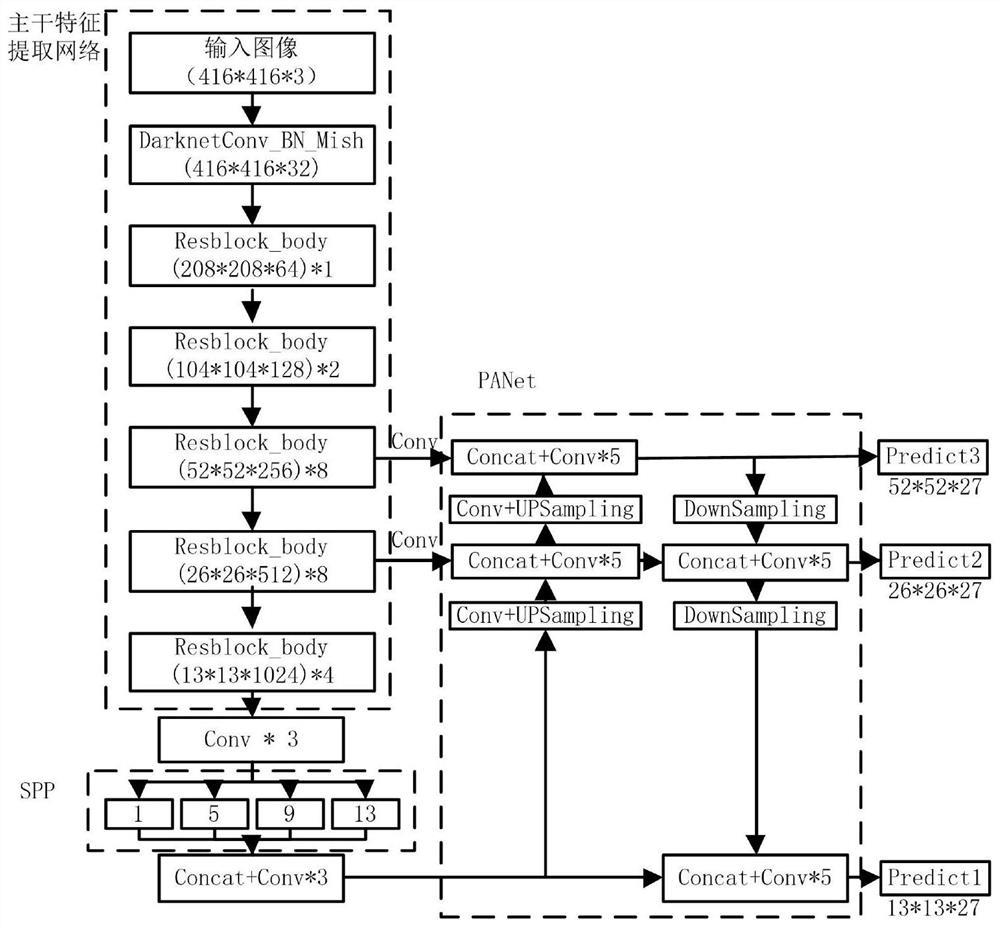

[0045] like figure 1 Shown is the detection flow chart of the hole detection intelligent detection auxiliary system of the gas turbine engine. First, a data set for training the neural network is constructed. In the embodiment of the present invention, the high-pressure turbine part of the aero-engine is taken as the research object, and the defects of the high-pressure turbine are roughly divided into four categories: ablation, cracks, missing coatings, and missing materials. The training data is collected from the hole detection data of a major repair factory in China, the maintenance data of the hole detection of an airline, the hole detection data of an airline's lease withdrawal, and the self-built data of the hole detection instrument.

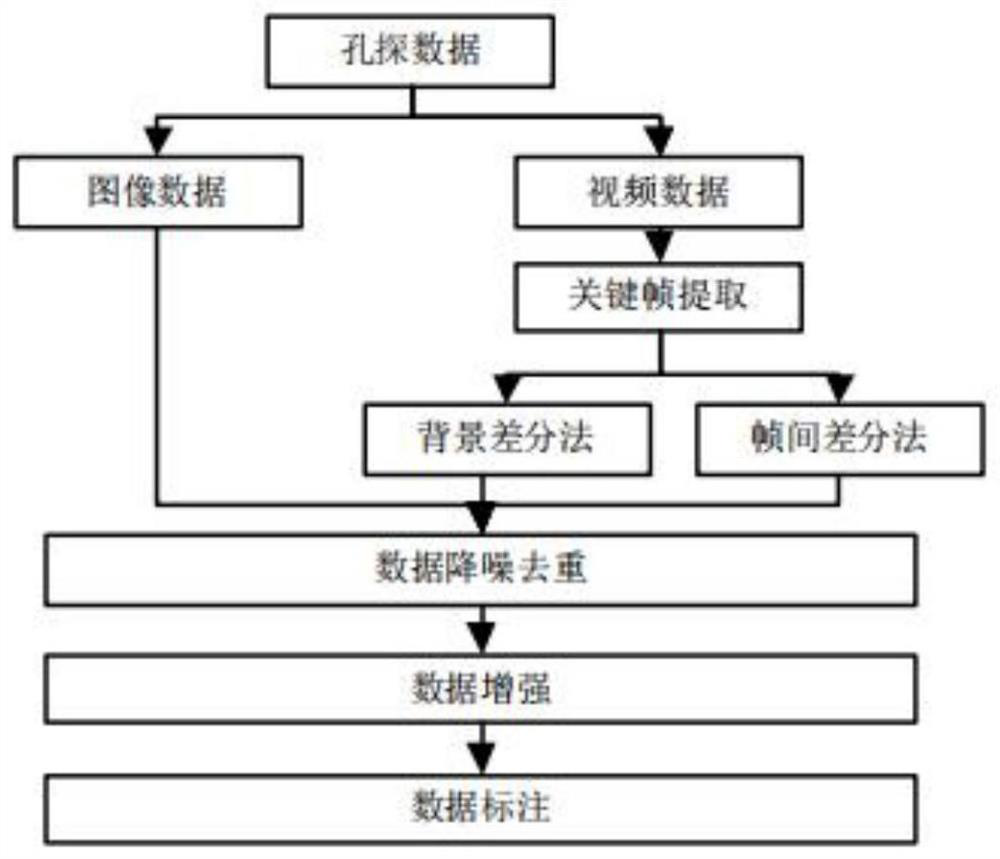

[0046] The hole detection data of the engine usually collected are mostly video files, such as figure 2Shown is the processing flow chart of hole detection data. Because the original hole detection video data has problems such as stron...

Embodiment 2

[0079]This embodiment constructs an auxiliary system for hole detection intelligent detection of a gas turbine engine, such as Figure 7 As shown in the figure, it includes a data set building module, a defect detection model building and training module, a local area network building module, a server-side running display module, and a Raspberry Pi-side UI interface; among them, the data set building module is used to sequentially perform data samples on the hole exploration data. Collection, data sample processing, and data sample labeling, to obtain a data set for training the neural network; the defect detection model building and training module, based on the data set used to train the neural network, build an experimental environment platform for the engine defect detection model and conduct engine defect detection models. The defect detection model is trained to obtain the optimal model of engine defect detection; the local area network building module is used to send the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com