Integrated high-temperature formic acid fuel cell

A formic acid fuel cell and fuel cell technology, which is applied to fuel cells, fuel cell additives, fuel cell heat exchange, etc., can solve the problems of low specific power and thermal efficiency of the system, complex stacks, and many devices, etc., to improve specific power. , the effect of simplifying the system and reducing the number of devices

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

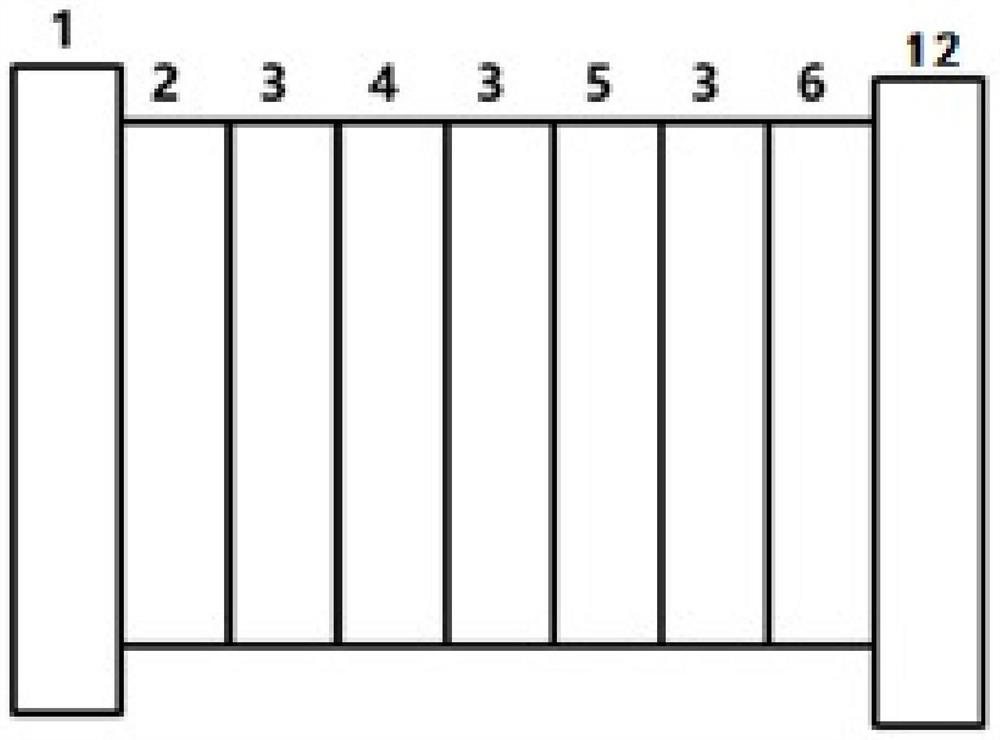

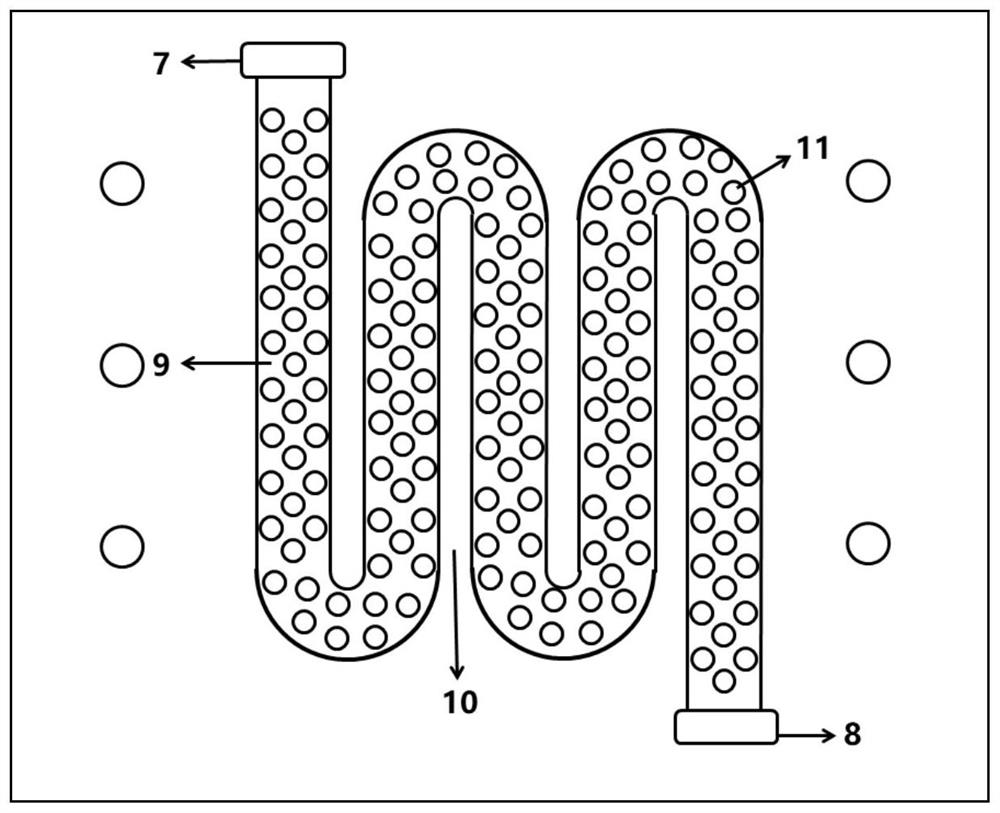

[0028] The integrated high-temperature formic acid fuel cell includes a first end plate 1 , a reaction substrate 2 , an anode plate 4 , a high-temperature membrane electrode 5 , a cathode plate 6 and a second end plate 12 which are sequentially stacked. The base material of the first end plate 1 and the second end plate 12 is stainless steel, the surface is plated with gold to realize the purpose of current collection, and an electric heating sheet is pasted on it and holes for positioning and screwing are punched. The high temperature membrane electrode 5 used is H 3 PO 4 / PBI system membrane electrode, the electrolyte membrane is phosphoric acid doped mPBI membrane, the cathode catalytic layer is composed of PtCo / C and PTFE, and the Pt loading is 1.0mg / cm 2 , the PTFE content is 20%; the anode catalytic layer is composed of Pt / C and PTFE, and the Pt loading is 0.6mg / cm 2 , the PTFE content is 10%; the cathode and anode diffusion layers are Toray carbon paper, the thickness...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| depth | aaaaa | aaaaa |

| area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com