Aluminum alloy decoration strip side vertical rib punching tool

An aluminum alloy and decorative strip technology, applied in the field of auto parts production equipment, can solve the problems of long milling production cycle, cumbersome processing procedures, low production efficiency, etc., and achieves reduction of processing production cycle time, short processing time and low cost. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

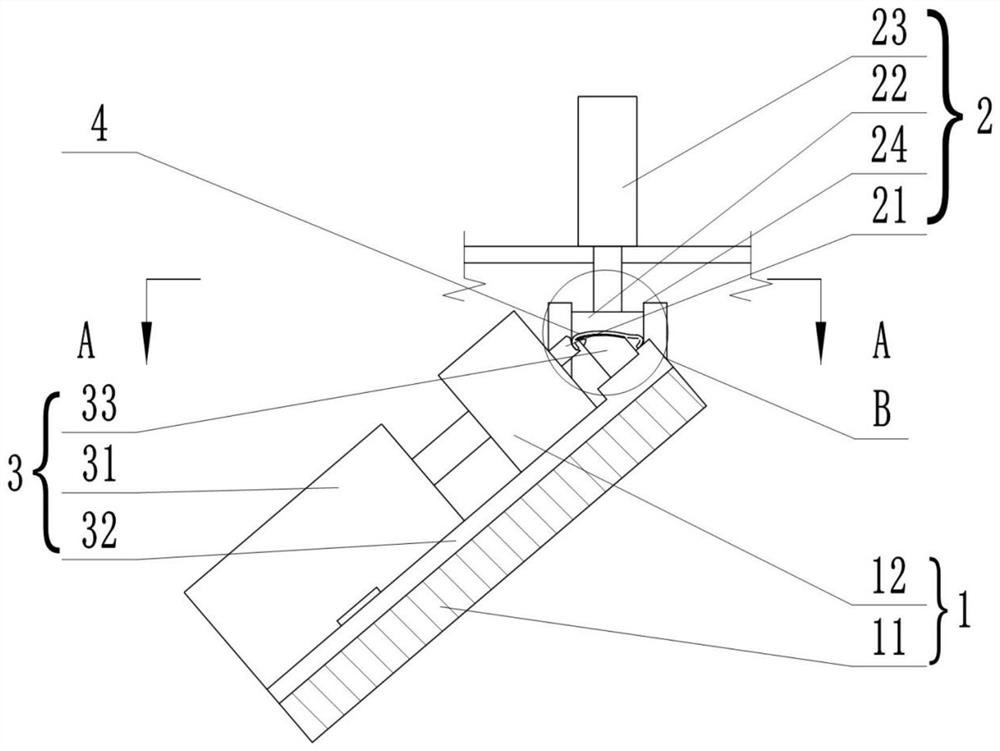

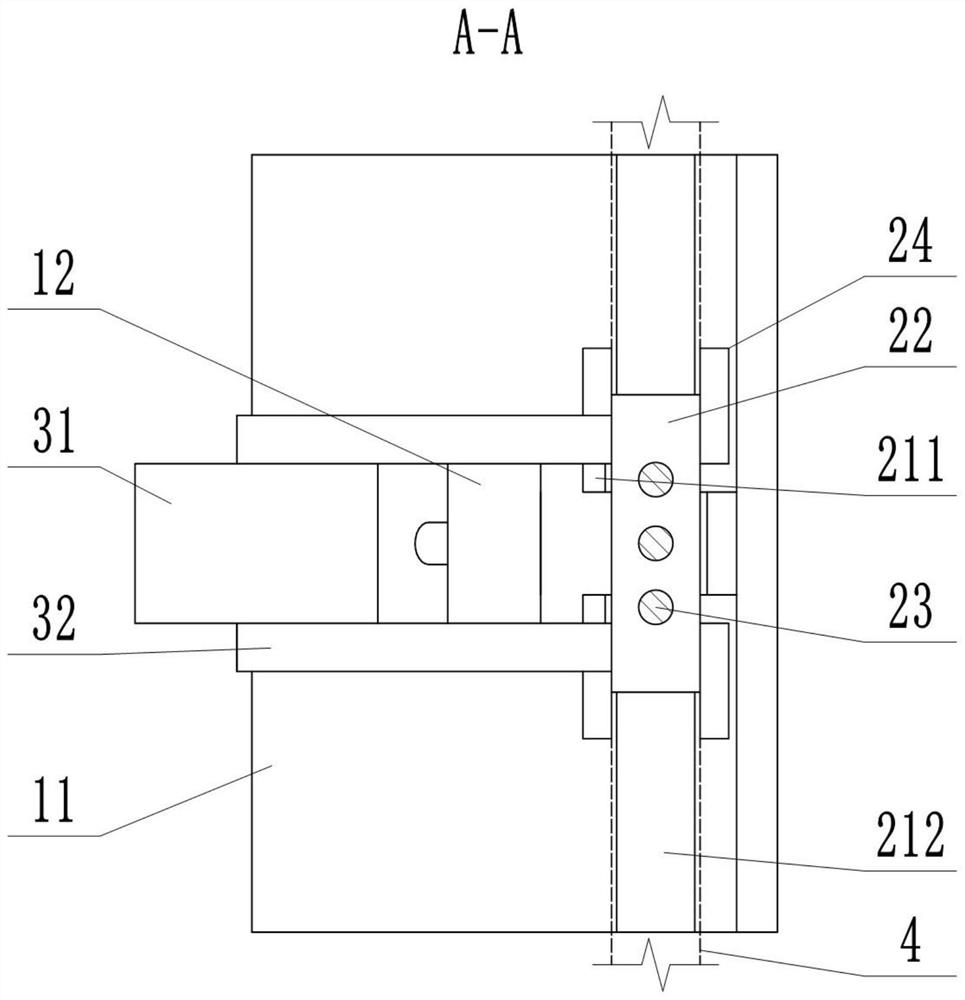

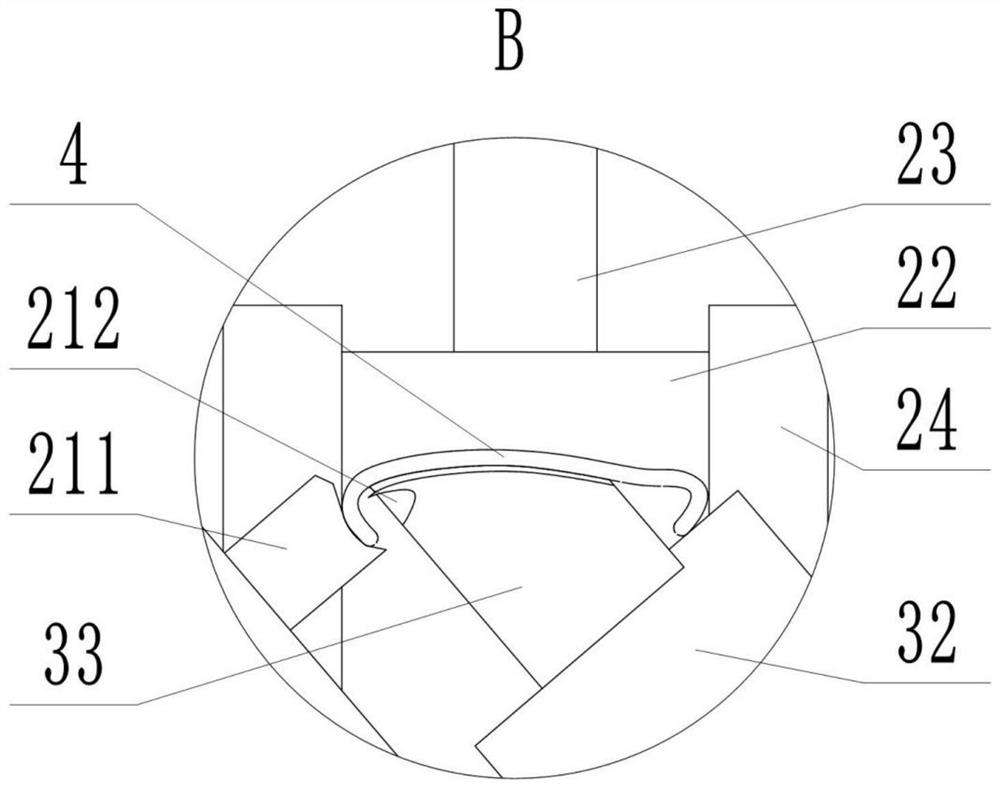

[0023] Below in conjunction with accompanying drawing and embodiment the present invention will be further described:

[0024] As shown, this embodiment includes:

[0025] The support structure 1, the support structure 1 includes a support plate 11 arranged obliquely, and a support block 12 is fixed on the support plate 11;

[0026] The binder structure 2, the binder structure 2 includes a plurality of support blocks 21 for supporting the decorative strip 4, the support block 21 includes two concave molds 211 for supporting the side ribs of the decorative strip 4 from obliquely below, the two Two dies 211 are fixedly connected with support plate 11 and / or support block 12 and are positioned at the both sides of punch 33 respectively, meanwhile, two dies 211 can also be merged into one, but it is necessary to arrange in the middle to facilitate punch 33 Movable groove; the lower part of the trim strip 4 punching position is also provided with a protruding support material bloc...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com