Metal straight bar round hole punching equipment

A straight bar and round hole technology, applied in the field of metal straight bar round hole punching equipment, can solve the problems of increased workload, falling on the ground, dirty ground, etc., to reduce labor intensity, improve work efficiency, and facilitate processing effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

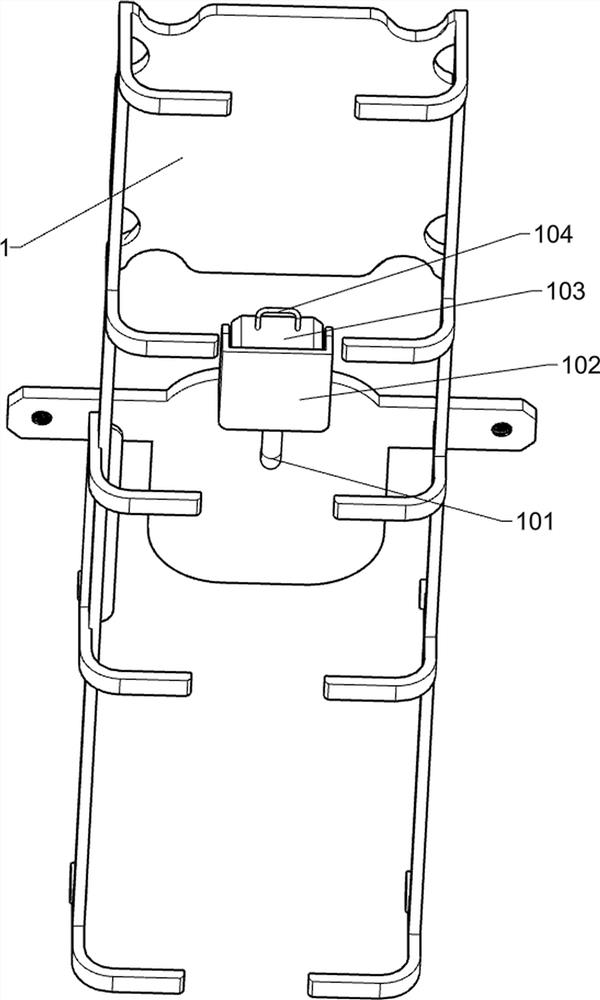

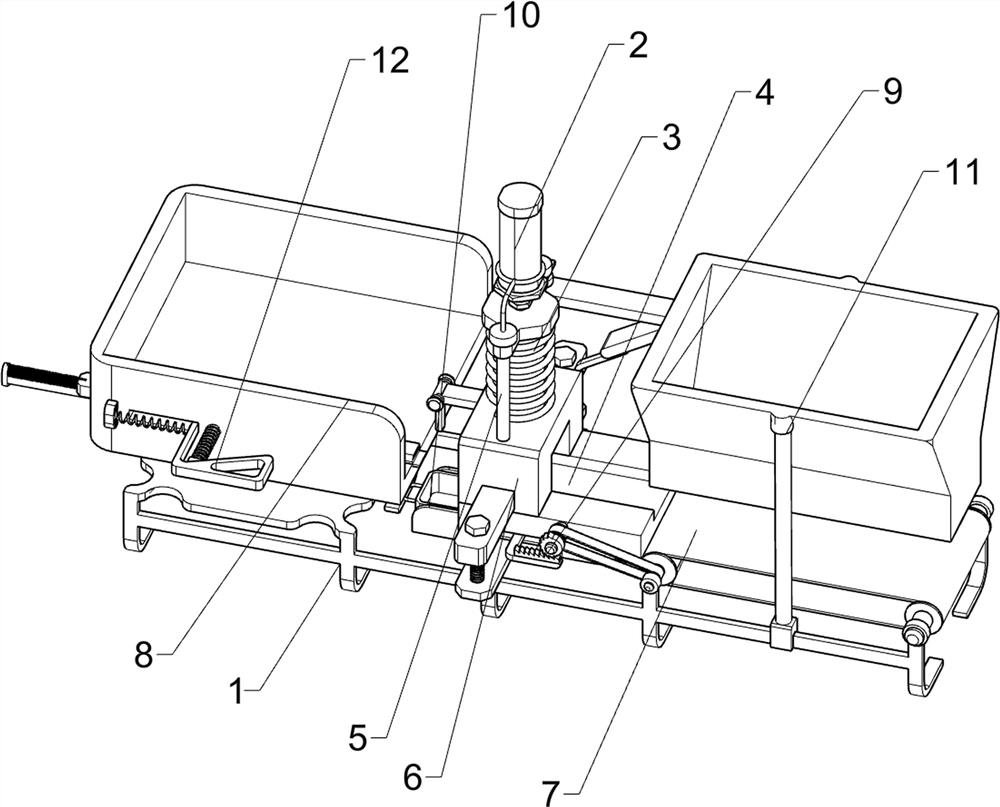

[0028] A metal straight bar punching round hole equipment, such as figure 1 and figure 2 As shown, it includes a base 1, a cylinder 2, an extruding column 3, a supporting platform 4, a pressing mechanism 5 and a fixing mechanism 6, the top of the base 1 is provided with a supporting platform 4, the top of the supporting platform 4 is provided with a fixing mechanism 6, and the fixing mechanism The top of 6 is provided with a pressing mechanism 5, the top of the pressing mechanism 5 is provided with a cylinder 2, and the bottom of the pressing mechanism 5 is provided with an extruding column 3, and the extruding column 3 is slidably connected with the fixing mechanism 6.

[0029] When people need to make round holes on the metal straight bar, people place the metal straight bar on the support table 4, under the action of the fixing mechanism 6, the metal straight bar is fixed, and then the cylinder 2 is started, and the piston rod of the cylinder 2 Under the action, the press...

Embodiment 2

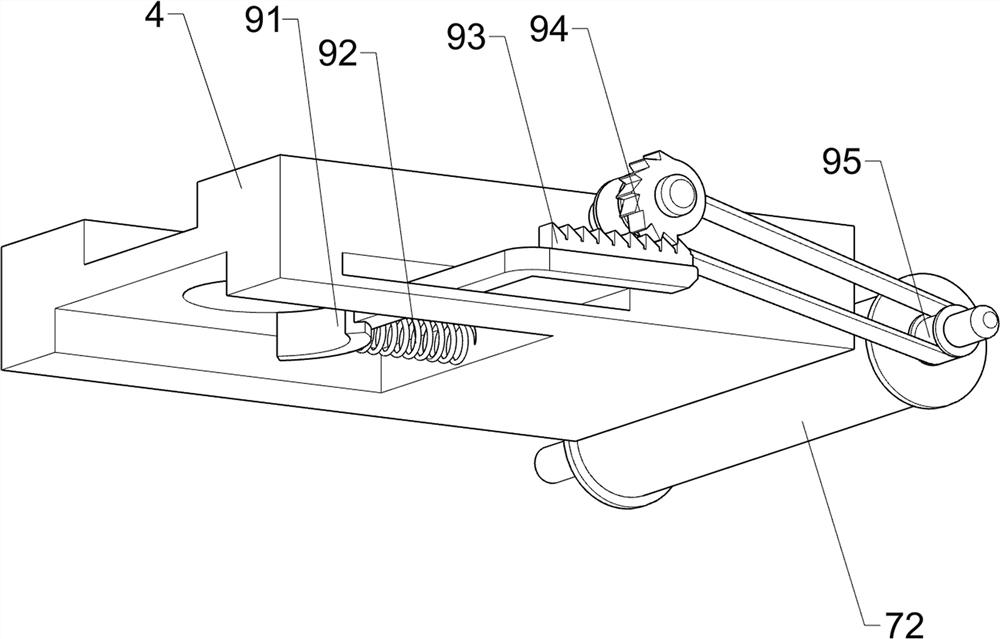

[0034] On the basis of Example 1, such as image 3 , Figure 4 , Figure 5 , Figure 6 and Figure 7 As shown, a feeding mechanism 7 is also included, and the feeding mechanism 7 includes a first rotating rod 71, a first transmission wheel assembly 72, a ratchet gear 73, a first ratchet bar 74, a first connecting rod 75, a block 76, a first Two springs 77, the third connecting block 78, the lower pressing rod 79, the third spring 710 and the second guide rod 711, the left side of the base 1 top symmetrical rotation type is provided with the first rotating rod 71, and the first rotating rod 71 is provided with There is a first transmission wheel assembly 72, the first transmission wheel assembly 72 is composed of rollers and conveyor belts, the rollers are respectively connected to the first rotating rod 71, the conveyor belt is connected between the rollers, and the outer front side of the first rotating rod 71 on the right is provided with A ratchet gear 73, a third conne...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com