Rapid segmentation cutting equipment for circuit board for electrical engineering

A technology of electrical engineering and cutting equipment, which is applied in the field of rapid segmental cutting equipment for circuit boards used in electrical engineering. The effect of the tightening effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

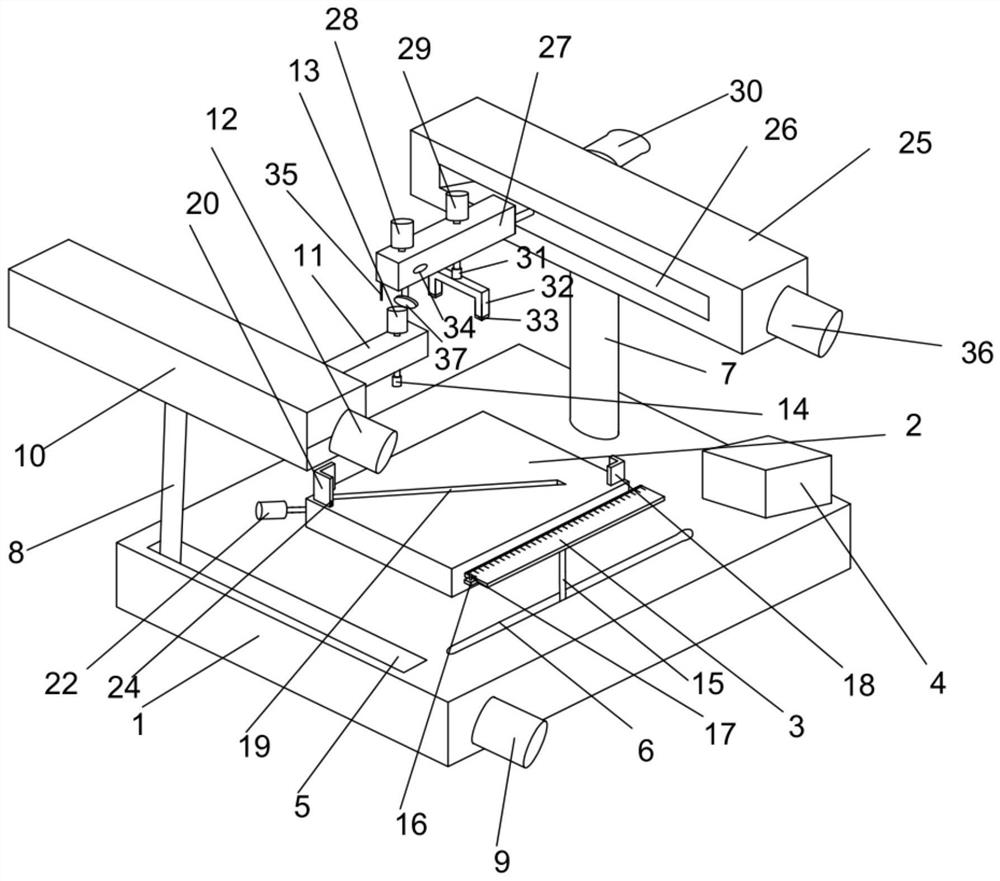

[0040] see Figure 1-Figure 6 , an embodiment provided by the present invention: a circuit board rapid segment cutting equipment for electrical engineering, including the following equipment:

[0041] a base 1;

[0042] A circuit board installation table 2 for placing circuit boards;

[0043] a scale 3 for positioning the base point;

[0044] a controller 4;

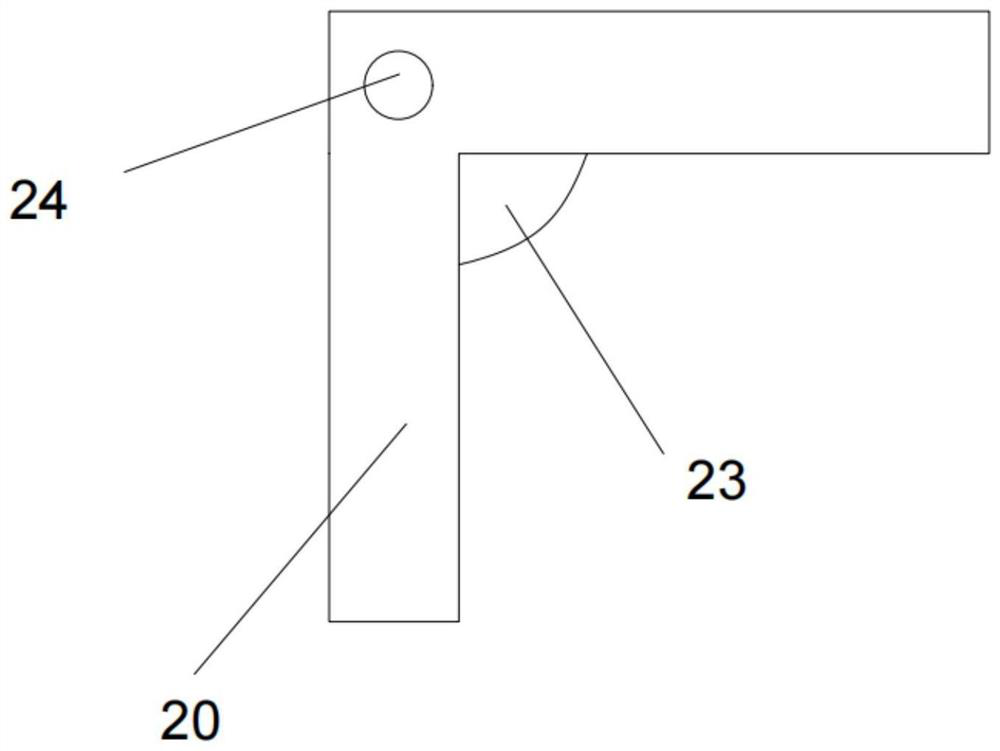

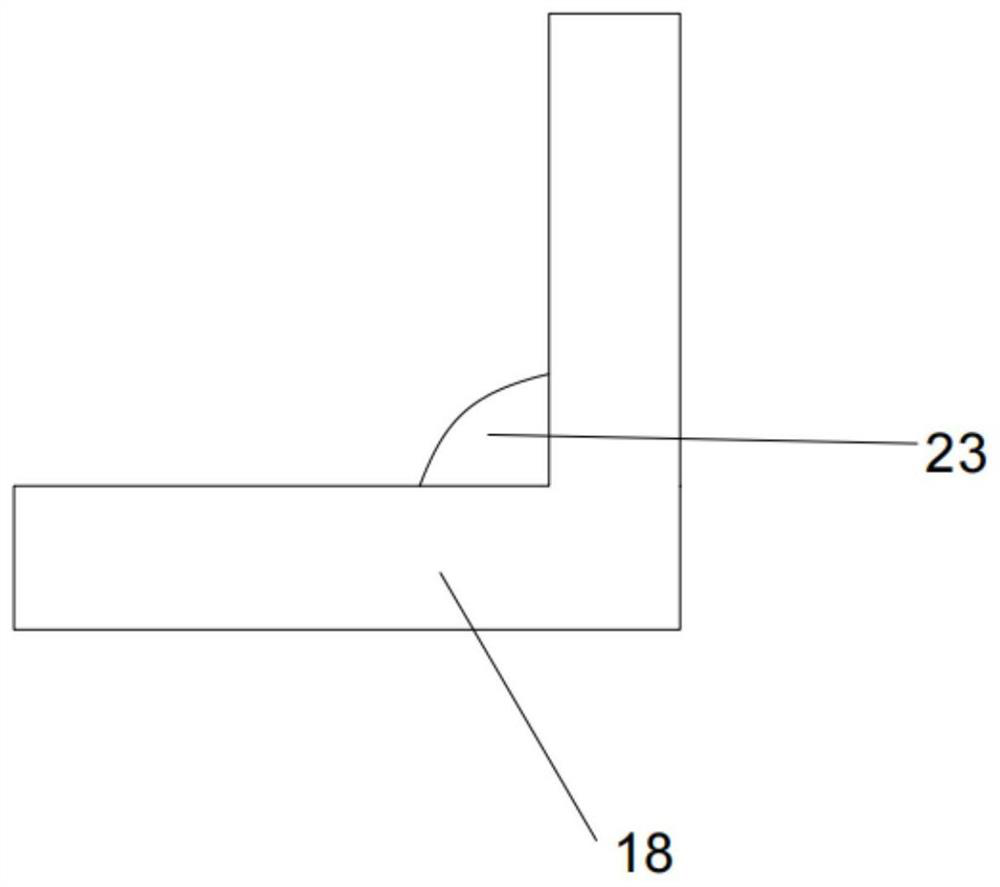

[0045] Wherein, the circuit board mounting platform 2 and the controller 4 are fixed on the base 1, and the base 1 is provided with a first chute 5 extending along the X-axis direction and a second chute extending along the Z-axis direction. 6 and the third vertical rod 7, the first vertical rod 8 is slidably connected in the first chute 5, and the first air cylinder that drives the first vertical rod 8 to slide in the first chute 5 is provided on the side of the base 1 9. A first crossbar 10 is arranged above the first vertical rod 8, the extending direction of the first crossbar 10 is consistent with the extending di...

Embodiment 2

[0054] see Figure 7 , a kind of embodiment that the present invention provides: a kind of circuit board fast segmental cutting equipment for electrical engineering, as a preference, in order to realize the function of positioning the origin of cutting, a positioning and dotting mechanism is arranged above the base 1, and the positioning and dotting mechanism Including the striker 44 plugged on the base 1, the lower end of the second connecting rod 27 is provided with an origin recognizer 45 electrically connected to the controller 4, by setting the striker 44, when the initial cutting position of the circuit board is positioned Finally, the dotting device 44 is manually removed and marked at the end of the circuit board cutting point, and then when the origin recognizer 45 recognizes the dot mark, the cutting process is carried out to ensure that the cutting is more accurate.

Embodiment 3

[0056] see Figure 8 , a kind of embodiment that the present invention provides: a kind of circuit board rapid section cutting equipment for electrical engineering, as preferably, be provided with alarm 46 on controller 4, by setting alarm 46 when equipment failure, give an alarm reminder.

[0057] Preferably, to improve the cutting effect, the cutter 37 is an infrared laser cutter.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com