MEMS sensor and preparation method thereof

A sensor and electrode layer technology, applied in the field of MEMS sensor and its preparation, can solve the problems of complex preparation process, large temperature drift, low reliability, etc., and achieve the effects of simplifying the preparation process, improving detection accuracy and reducing temperature drift

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

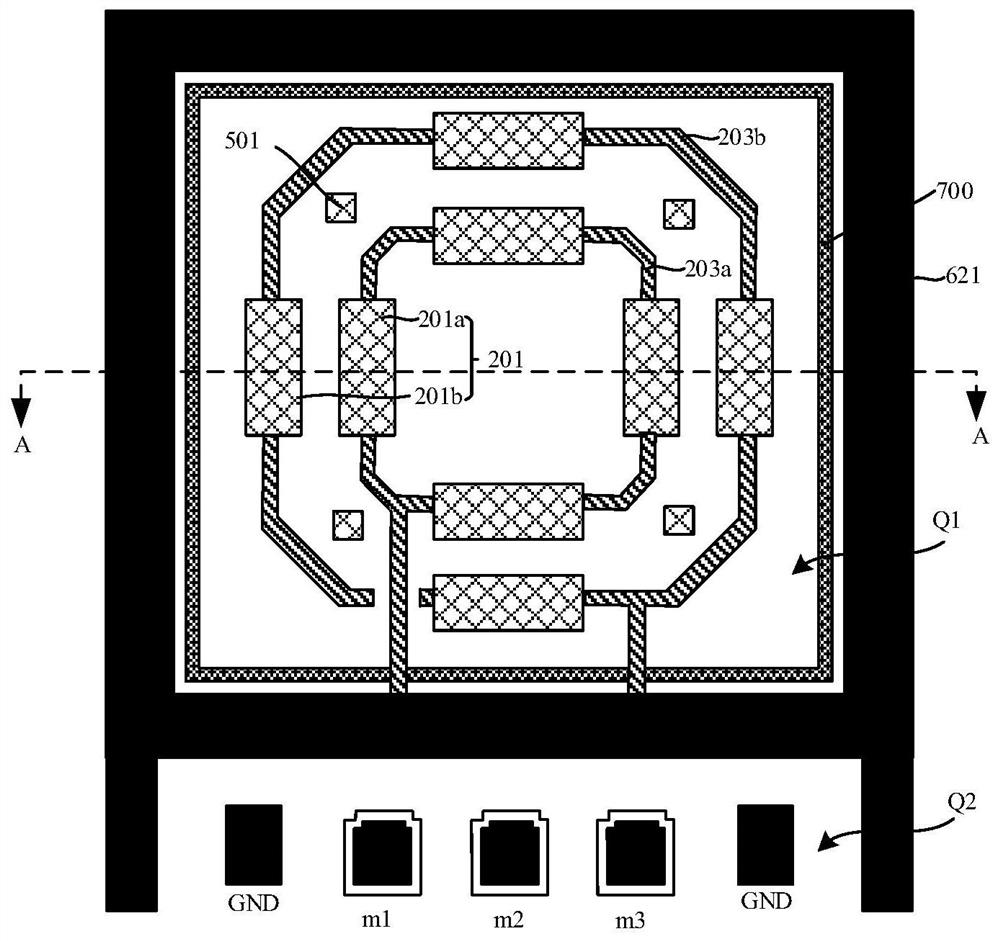

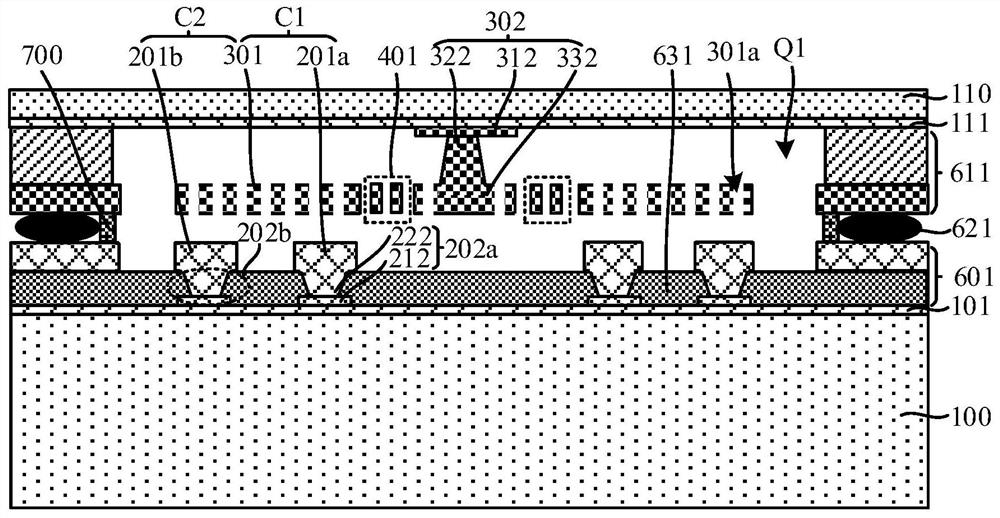

[0070] Figure 1a A schematic plan view of the first substrate provided in this embodiment, Figure 1b A schematic plan view of the second substrate provided in this embodiment, figure 2 A schematic cross-sectional view of the MEMS sensor along the direction AA is provided for this embodiment. In this embodiment, the MEMS sensor is a force sensor. Such as Figure 1a , Figure 1b and figure 2 As shown, the force sensor includes a first substrate 100, a second substrate 110 and a support structure between the first substrate 100 and the second substrate 110, the first substrate 100 The front side is opposite to the front side of the second substrate 110, and the support structure together with the first substrate 100 and the second substrate 110 forms a closed cavity Q1, wherein the first substrate The bottom 100 and the second substrate 110 serve as upper and lower surfaces of the cavity Q1 respectively, and the support structure serves as a side surface of the cavity.

...

Embodiment 2

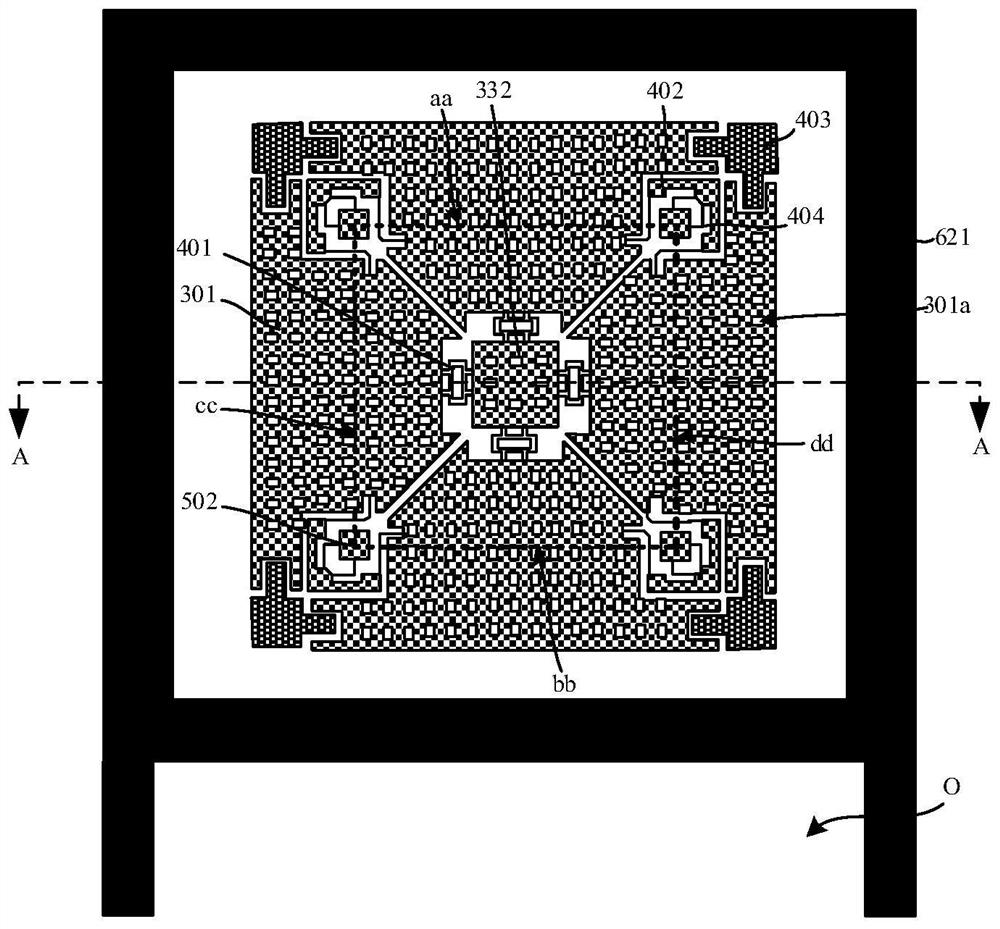

[0129] Figure 4 Schematic diagram of the structure of the first substrate provided in this embodiment, Figure 5 A schematic cross-sectional view of the MEMS sensor along the BB direction is provided for this embodiment. Such as Figure 4 and Figure 5 As shown, in this embodiment, the structure on the second substrate 110 is the same as that in Embodiment 1, and the structure on the first substrate 100 is different from that in Embodiment 1. Specifically, in this embodiment, each The two first conductive connection structures in each of the electrode groups are located in the region between the corresponding two first electrode layers 201, and the two first conductive connection structures are arranged close to each other.

[0130] read on Figure 4 and Figure 5 Taking the first electrode layer 201a and the first electrode layer 201b as an example, the first conductive connection structure 202a and the first conductive connection structure 202b are both located on the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com