Polymer concrete overlay and construction method thereof

A construction method and concrete technology, which can be applied to cohesive pavement paved on site, buildings, roads, etc., can solve the problems of easy deformation of the road surface, increased frictional resistance, and tire impact, so as to shorten the construction period, improve the flexural strength, extend the The effect of service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

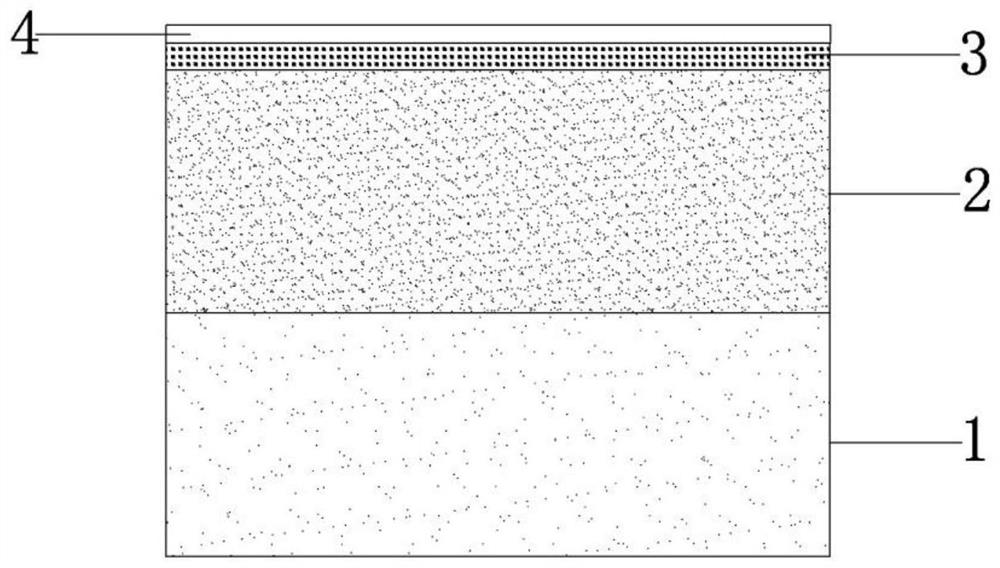

[0042] In this embodiment, the formula of the mixture for the aggregated concrete overlay is: 700 kg of crushed stones of 5 cm to 10 cm, 580 kg of crushed stones of 3 cm to 5 cm, 580 kg of medium sand of 0 to 2 cm, 360 kg of 42.5 ordinary Portland cement, epoxy resin glue 5kg, 0.9kg of polypropylene fiber (the specification is 20cm in length), 179kg of water, and the thickness of laying is 7cm. The formula of the mixture for the protective layer is: 50kg of 42.5 ordinary Portland cement, 10kg of epoxy resin glue, 1kg of water-soluble pigment and 300kg of water, and the thickness of the laying is 5cm.

[0043] The construction method of the polymeric concrete overlay of above-mentioned formula is:

[0044] 1) Use a forced cement concrete mixer to mix the mixture of the above formula evenly, and the time for mixing the mixture is 100 to 110 seconds.

[0045] 2) After the working surface is cleaned by the knapsack blower, install the lateral formwork on the outside of the workin...

Embodiment 2

[0051] The difference between this example and Example 1 is that the formula of the aggregated concrete overlay is: 300kg of crushed stones of 10cm to 13cm, 500kg of crushed stones of 5cm to 10cm, 480kg of medium sand of 2 to 5cm, and 42.5kg of ordinary Portland cement. 360kg, 5kg of epoxy resin glue, 0.9kg of polypropylene fiber (the specification is 26cm in length), 170kg of water, and the thickness of the laying is 10cm.

[0052] The difference between the construction method of the aggregated concrete overlay of the above formula and that of Example 1 is that the mixing time of the mixture is 110 to 120 seconds; a rubber-wheeled road roller of more than 30T is used, and rubber rollers are not mixed with aggregated concrete. The mixture is sticky, and it is placed for 30 to 50 minutes after the rolling is completed. After the surface of the material "sweats", use a double-drive double-vibration road roller to perform surface finishing operations, and roll it into an overcoat...

Embodiment 3

[0055] The difference between this example and example 2 is: the formula of the mixture of aggregate concrete overlay is: 12cm~20cm gravel 300kg, 5cm~10cm gravel 500kg, 3cm~5cm medium sand 580kg, 42.5 ordinary portland cement 360kg , 5kg of epoxy resin glue, 0.9kg of polypropylene fiber (the specification is 40cm in length), 170kg of water, and the thickness of the laying is 16cm.

[0056] The difference between the construction method of the aggregated concrete overlay of the above formula and that of Example 1 is that the mixing time of the mixture is 120 to 140 seconds; a rubber-wheeled road roller of more than 30T is used, and rubber rollers are not mixed with aggregated concrete. The mixture is sticky, and it is placed for 50 to 60 minutes after the rolling is completed. After the surface of the material "sweats", use a double-drive double-vibration road roller to perform surface finishing operations, and roll it into a cover layer with a thickness of 16cm.

[0057] The v...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com