Scratch-resistant epoxy-modified polyester back paint for coils with high coating rate and preparation method thereof

An epoxy-modified polyester, coating rate technology, applied in polyester coatings, coatings, anti-corrosion coatings, etc., can solve the problems of poor paint film processability, low coating rate, low epoxy resin solid content, etc. To achieve the effect of strong humidity and heat resistance, good surface smoothness, and increased stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

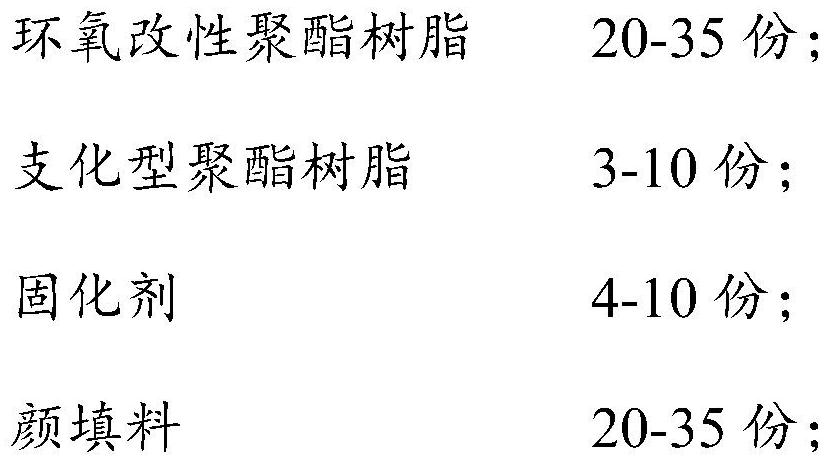

Method used

Image

Examples

Embodiment Construction

[0045] The technical solutions of the present invention will be further described in detail below through examples. The scope of the present invention is not limited by the specific embodiments but by the scope of the claims.

[0046] Under the situation that the purpose of the present invention is clarified and explained through the following examples, the components of the composition are all explained in parts by weight as a general standard. Unless otherwise specified, for the sake of brevity, "parts" and "parts by weight" in the embodiments of the present invention have the same meaning.

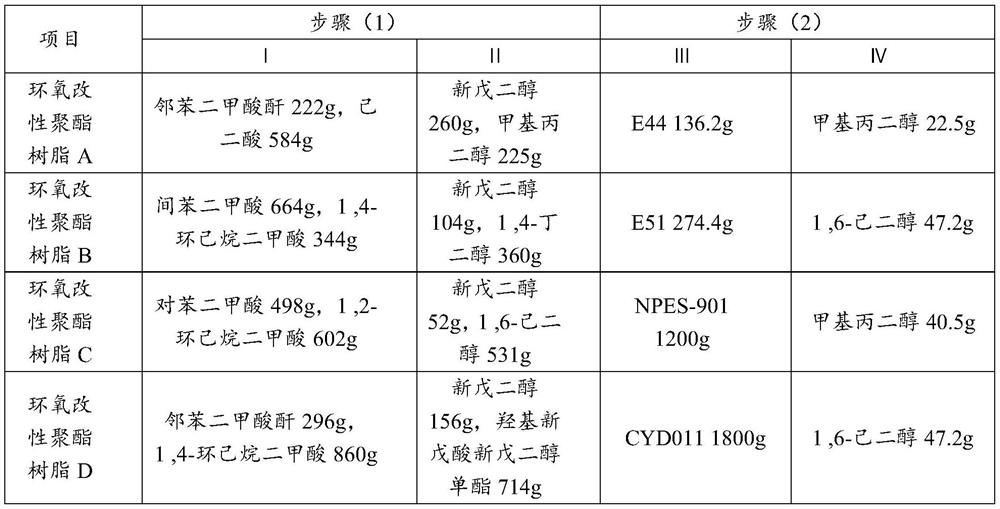

[0047] Epoxy-modified polyester resin A-T described in embodiment 1-60 is prepared according to the following operation steps:

[0048] Step (1): Put I, II (see Table 1) and solvent xylene in the formula into a clean reaction flask equipped with stirring, thermometer, water separator, fractionating column, and inert gas inlet, and wait for the material to melt. , start stirring, and p...

PUM

| Property | Measurement | Unit |

|---|---|---|

| acid value | aaaaa | aaaaa |

| hydroxyl value | aaaaa | aaaaa |

| epoxy value | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com