Pressing energy storage rebound mechanism

A rebound mechanism and energy storage technology, applied in the direction of building components, building structures, applications, etc., can solve problems affecting the stability of furniture products, affecting the overall appearance of furniture products, occupying the space position of furniture products, etc., to achieve the benefit of the overall Simple setting, convenient daily use and maintenance, and the effect of reducing space location

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0039] The present invention will be further described below in conjunction with the accompanying drawings and embodiments.

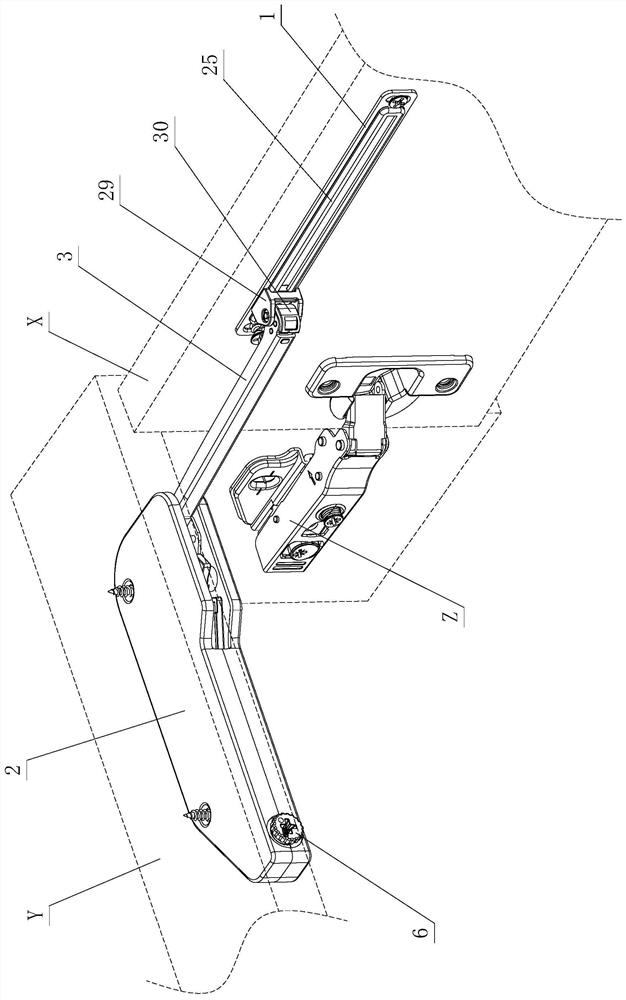

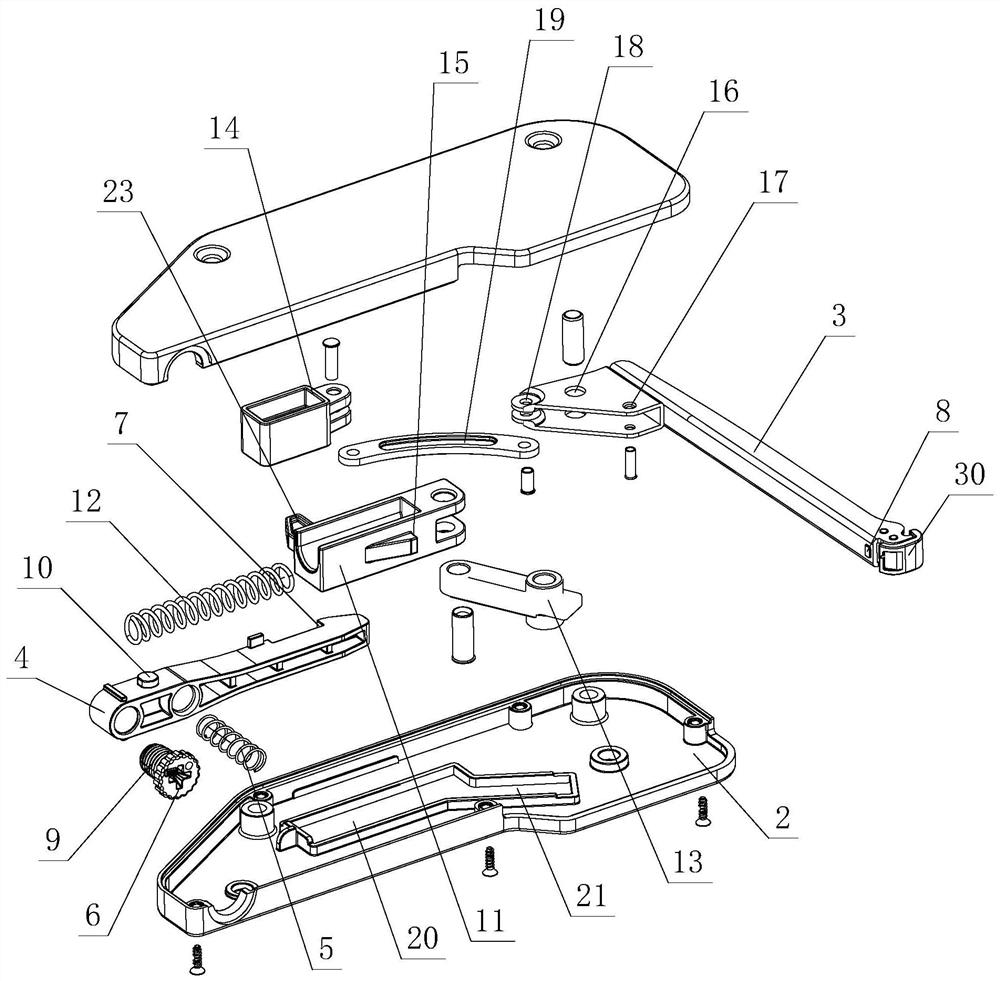

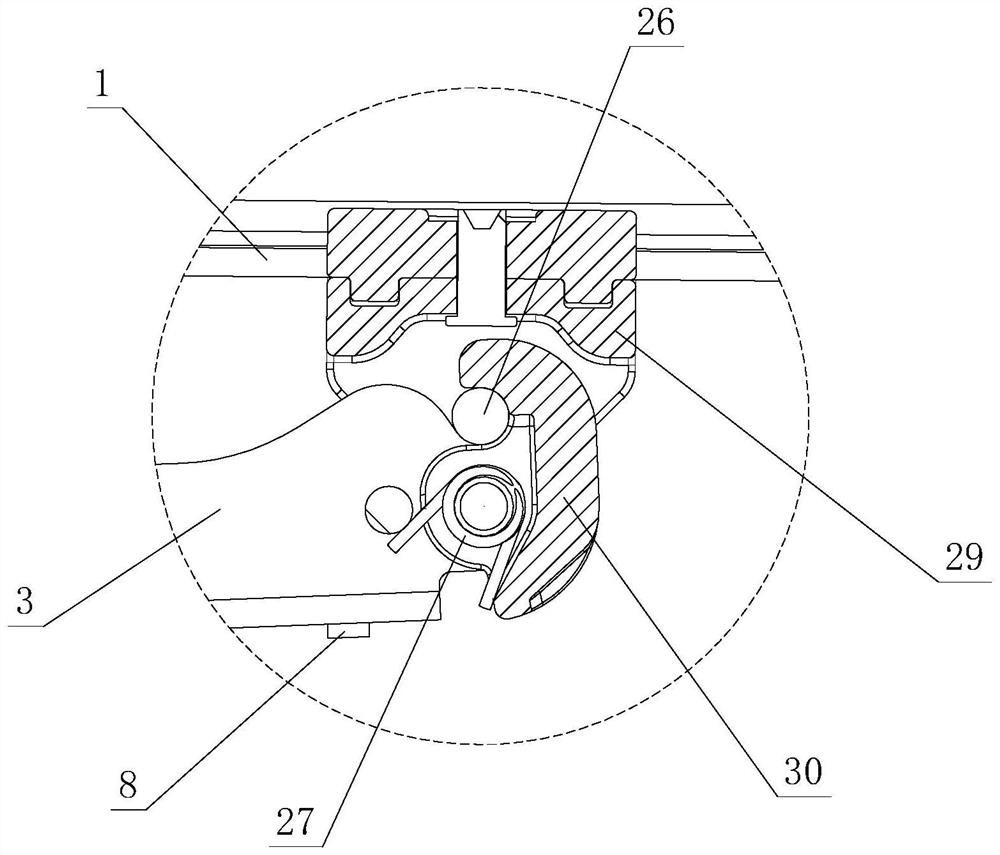

[0040] see Figure 1-Figure 13 , the pressing energy storage rebound mechanism includes a rebound device and an assembly element 1; the rebound device includes a bracket element 2, and the bracket element 2 is provided with a pressing assembly, a pushing assembly and a connecting arm 3; the pressing assembly and the pushing assembly are independent of each other set, and elastically move on the support element 2 respectively; the connecting arm 3 is hinged to open and close on the support element 2, and a transmission assembly is arranged on it, and is driven and connected to each other through the transmission assembly and the push assembly; the connection arm 3 A disassembly assembly is provided between the assembly element 1, and the two are disassembled and connected through the disassembly assembly; the connecting arm 3 slides on the assembly eleme...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com