Configurable constant current charging management system

A technology of constant current charging and management system, applied in the direction of collectors, electric vehicles, electrical components, etc., can solve the problems of increased cost of linear circuits, inability to meet customers, high costs, etc., to improve service life, solve large volume, increase The effect of large impedance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0027] The specific implementation manner of the present invention will be described in detail below in conjunction with the accompanying drawings and preferred implementation examples.

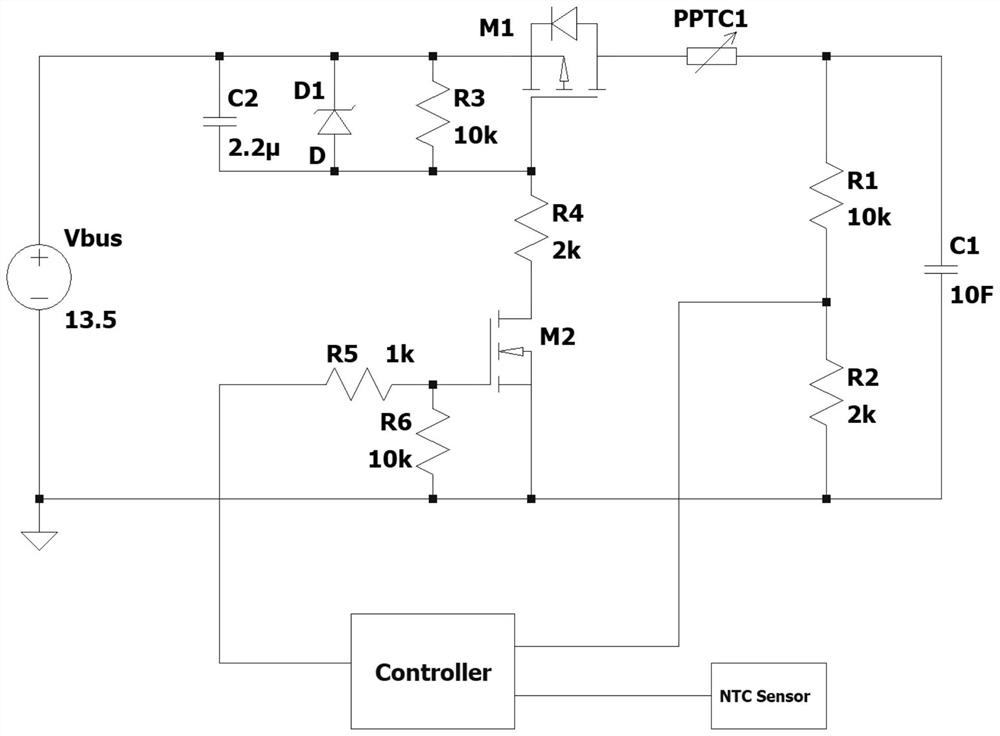

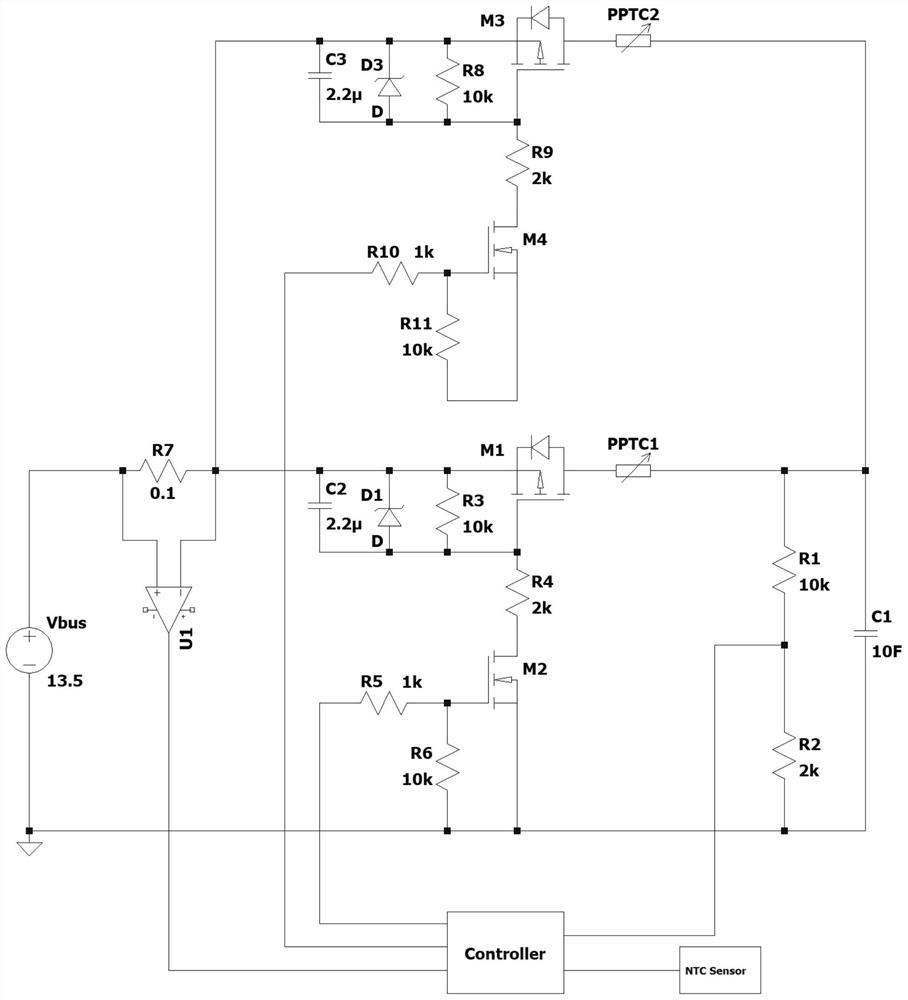

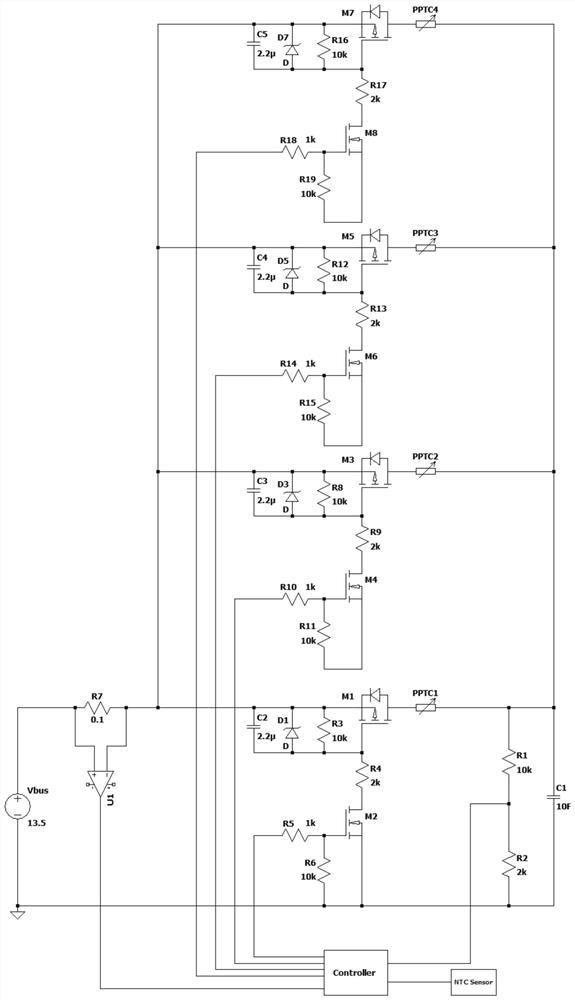

[0028] First, let's introduce the working principle of the basic step-down constant current charging circuit. The circuit structure is as follows: figure 1As shown, resistors R1 and R2 form the voltage acquisition module of devices to be charged such as supercapacitors, field effect transistors M1 and M2, Zener diode D1, resistors R3, R4, R5, R6, and buffer capacitor C2 form the enabling trigger of the charging circuit Module, the processor Controller is used to collect external voltage, ambient temperature, current and other signals, and do corresponding logic control. The NTC sensor is used to collect the ambient temperature and transmit it to the processor controller. The working process is as follows:

[0029] After powering on for the first time, the processor first detects the voltage o...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com