Heating cigarette smoking set with variable airway pressure and using method thereof

A technology of variable and variable air pressure, applied in the direction of tobacco, etc., can solve the problems of high equipment cost, change of cigarette production process, and influence on the taste of smoking, so as to improve the utilization rate of heat energy, increase the release, and ensure the effect of taste

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

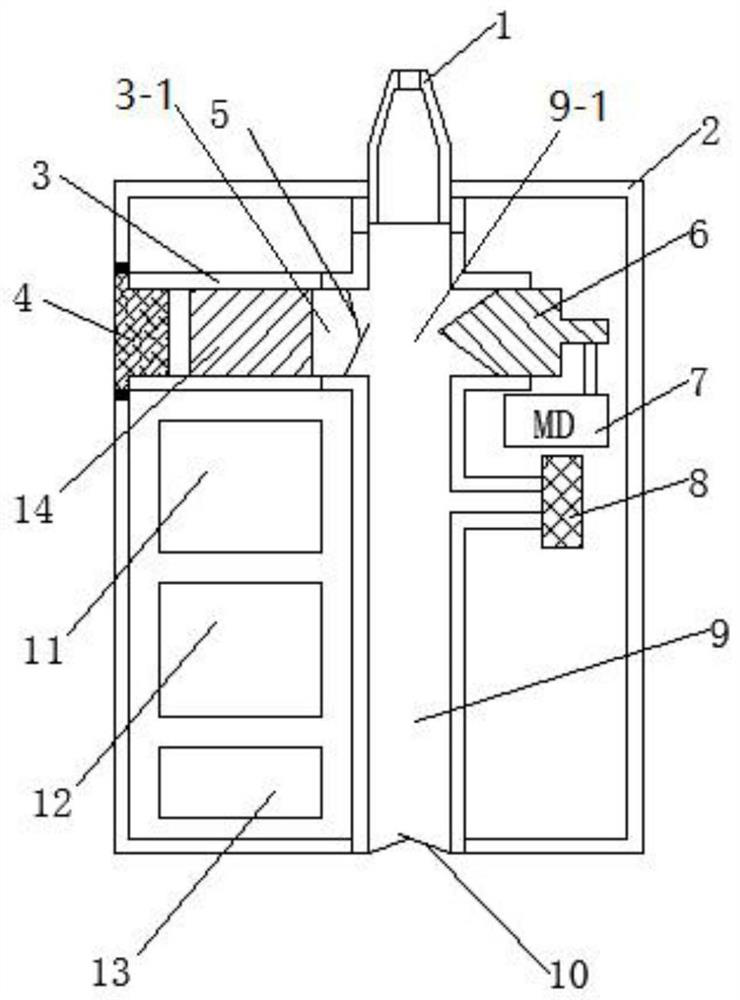

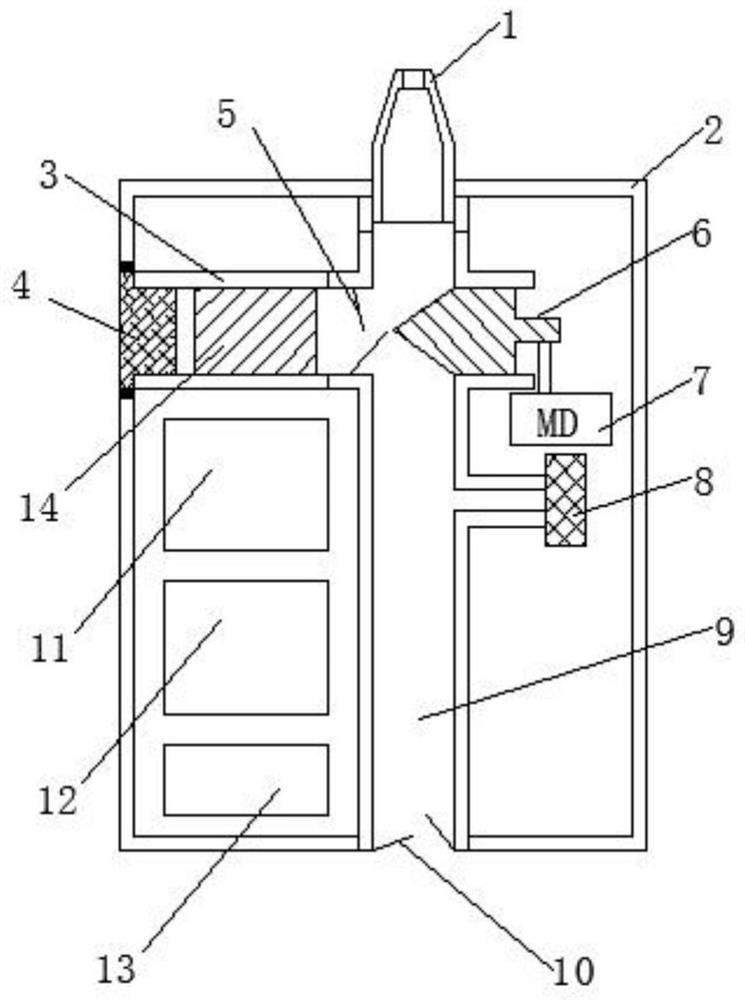

[0042] Such as Figure 1-2 , a heated cigarette smoking set with variable airway pressure, the smoking set includes a suction nozzle 1, a casing 2, a heating chamber 3, a sealing sleeve 4, a first one-way control valve 55, a piston 6, a motor 7, an air pressure sensor 8, The main airflow channel 9 , the second one-way control valve 510 , the control module 11 , the power module 12 , the charging module 13 , and the tobacco segment 14 .

[0043] The sealing sleeve 4 is located outside the heating cavity 3 and is used to seal the tobacco segment 14, and the sealing sleeve 4 and the outer shell 2 are snap-fitted. The surroundings of the heating chamber 3 are sealed, and only the flue gas outlet 3-1 is provided.

[0044] The main airflow channel 9 has a channel section variable section 9-1.

[0045] The suction nozzle 1 is located above the smoking appliance and closely connected with the main airflow channel 9;

[0046] The heating chamber 3 is located on one side of the varia...

Embodiment 2

[0059] The using method of embodiment 1 smoking set is as follows:

[0060] Include the following steps:

[0061] (1) Put the tobacco segment in the heating cavity, start the smoking appliance, and after the preheating is completed, the user smokes through the suction nozzle 1;

[0062] (2) The user generates a negative pressure in the main airflow channel 9 through suction, the second one-way control valve 10 is opened, and the air pressure sensor 8 senses the air pressure change to generate a signal;

[0063] (3) The air pressure sensor 8 outputs a signal to the control module 11, and the control module 11 controls the rotation of the motor 7;

[0064] (4) The motor 7 controls the piston 6 to move in a direction close to the channel section variable section 9-1. At this time, the section of the channel section variable section 9-1 becomes smaller. According to the Venturi effect, a negative pressure is formed here to open the first one-way control valve 5, and the flue gas...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap