Magnesium alloy bone splint doped with hydroxyapatite and capable of inhibiting tumour proliferation and preparation method of magnesium alloy bone splint

A hydroxyapatite and magnesium alloy technology, which is applied in the directions of additive manufacturing, additive processing, and process efficiency improvement, can solve problems such as not considering functional requirements, and achieves inhibition of tumor proliferation, promotion of repair, and satisfaction of surface accuracy. and mechanical properties

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

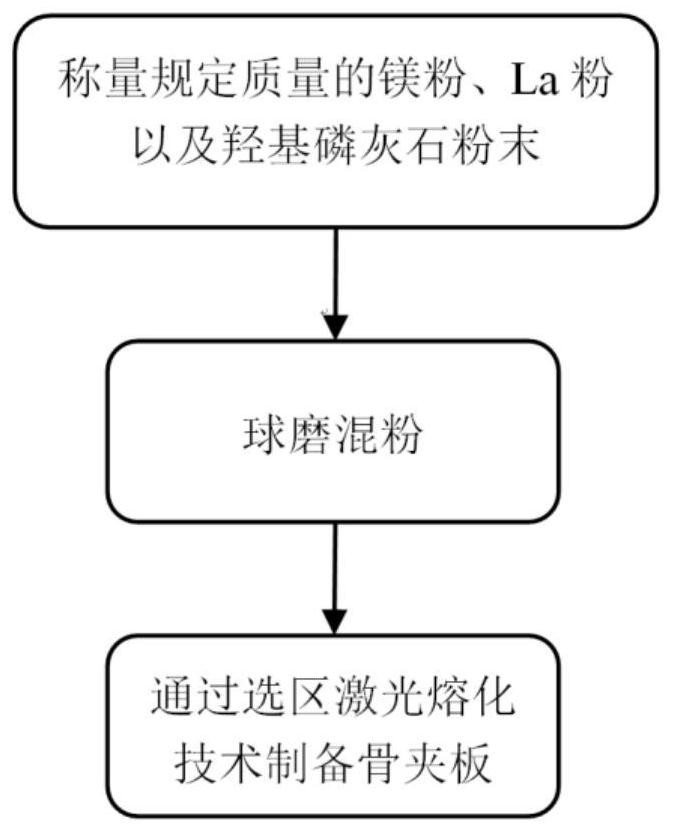

[0027] The present invention also provides a preparation method of a magnesium alloy bone splint doped with hydroxyapatite and inhibiting tumor growth, such as figure 1 shown, including the following steps:

[0028] Step 1, weighing:

[0029] Raw materials are weighed according to the following weight percentages: La powder: 2-3%, hydroxyapatite powder: 3-12%, the balance is atomized magnesium powder, and the sum of the weight percentages of the above components is 100%;

[0030] Step 2, ball milling and mixing:

[0031] Place the weighed raw material powder in a horizontal high-energy ball mill for ball milling to promote the thorough mixing of hydroxyapatite with atomized magnesium powder and La powder;

[0032] In step 2, ball milling process parameters: ball to material weight ratio 1:1, rotating speed 100-200r / min, ball milling time 8-12h, rest 10min at intervals of 1h and alternate forward and reverse rotation to ensure that the temperature of the tank will not be too ...

Embodiment 1

[0038] Step 1. Weighing:

[0039] Weigh the raw materials according to the following weight percentages: La powder: 2%, hydroxyapatite powder: 3%, the balance is atomized magnesium powder, and the sum of the weight percentages of the above components is 100%;

[0040] Step 2, ball milling and mixing:

[0041] Put the weighed powder in a horizontal high-energy ball mill for ball milling and mixing. Ball milling process parameters: ball to material weight ratio 1:1, speed 100r / min, ball milling time 10h, rest 10min at intervals of 1h and alternate forward and reverse rotation to ensure the tank The temperature will not be too high. The grinding tank is filled with argon to protect the powder from oxidation. The grinding balls used are: boron carbide grinding balls with a diameter of Φ5mm and Φ10mm, and the weight ratio of large and small balls is 1:1;

[0042] Step 3. Selected area laser melting forming:

[0043] Put the prepared magnesium alloy powder into the selective las...

Embodiment 2

[0046] Step 1. Weighing:

[0047] Weigh the raw materials according to the following weight percentages: La powder: 2.5%, hydroxyapatite powder: 12%, the balance is atomized magnesium powder, and the sum of the weight percentages of the above components is 100%;

[0048] Step 2, ball milling and mixing:

[0049] Put the weighed powder in a horizontal high-energy ball mill for ball milling and mixing. Ball milling process parameters: ball to material weight ratio 1:1, speed 150r / min, ball milling time 8h, rest 10min at intervals of 1h and alternate forward and reverse rotation to ensure that the tank The temperature will not be too high. The grinding tank is filled with argon to protect the powder from oxidation. The grinding balls used are: boron carbide grinding balls with a diameter of Φ5mm and Φ10mm, and the weight ratio of large and small balls is 1:1;

[0050] Step 3. Selected area laser melting forming:

[0051] Put the prepared magnesium alloy powder into the select...

PUM

| Property | Measurement | Unit |

|---|---|---|

| density | aaaaa | aaaaa |

| size | aaaaa | aaaaa |

| Vickers hardness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com