Mobile cable-parallel spraying equipment for segmental coating of ships

A mobile and parallel technology, applied in the direction of the spraying device, can solve the problems of cumulative error, large end inertia, and threat to workers' health, and achieve the effect of increasing the allowable error range, small end cumulative error, and wide range of motion spraying

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0036] The technical solutions of the present invention will be further described in detail below with reference to the embodiments and the accompanying drawings.

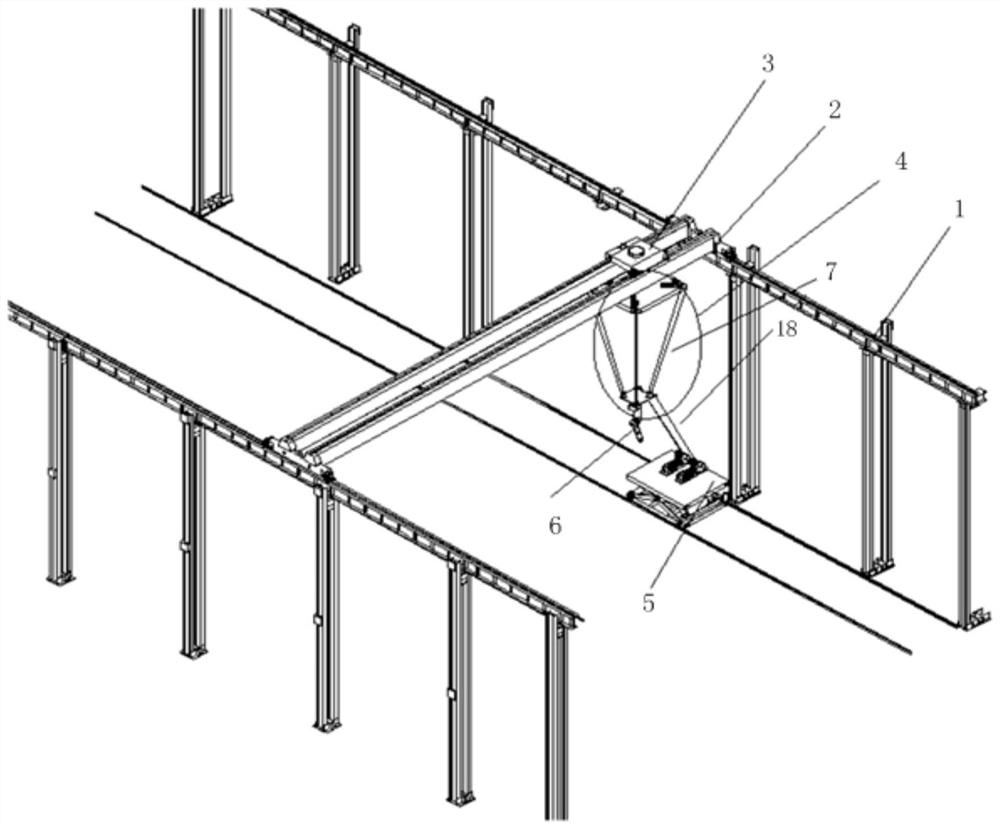

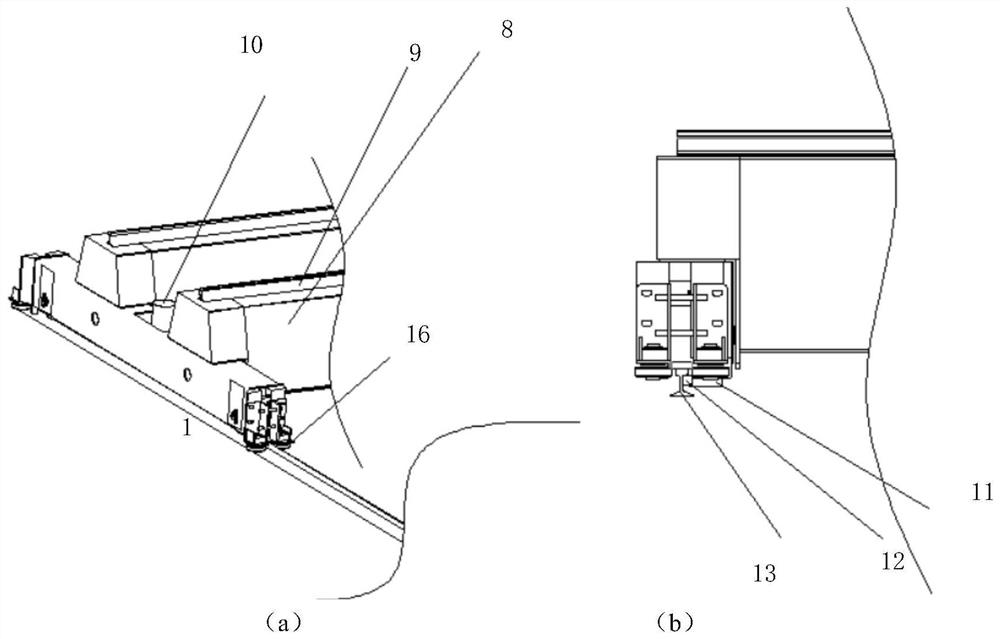

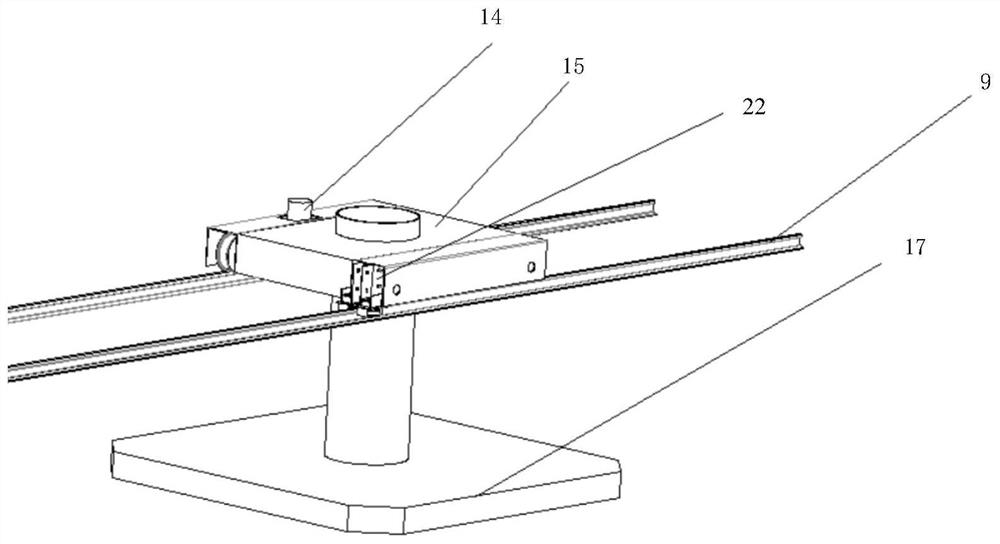

[0037] A mobile cable-parallel spraying equipment for ship segment painting, comprising a supporting carriage 1, a Y-direction moving mechanism 2 in the air, an X-direction moving mechanism 3 in the air, a Z-direction adjustment mechanism 4, and a ground rail Y-direction moving hydraulic lift Platform 5, spraying robot arm 6.

[0038] like figure 1 As shown, a pair of parallel supporting carriages 1 are arranged extending along the Y-direction, and each side of the supporting carriages 1 includes a Y-direction rail 13 . The air Y-direction moving mechanism 2 is horizontally mounted between the two supporting carriages 1, and its two ends are slidably connected with the Y-direction rails 13 of the supporting carriages 1, and are driven by gear racks to realize the spraying robot arm 6 in the Y-direction. sports. ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com