Intelligent and efficient roll paper unwinding and cutting machine

A paper cutter and roll paper technology, applied in metal processing and other fields, can solve the problems of easily damaged paper, low efficiency, and inability to adjust paper tension in real time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

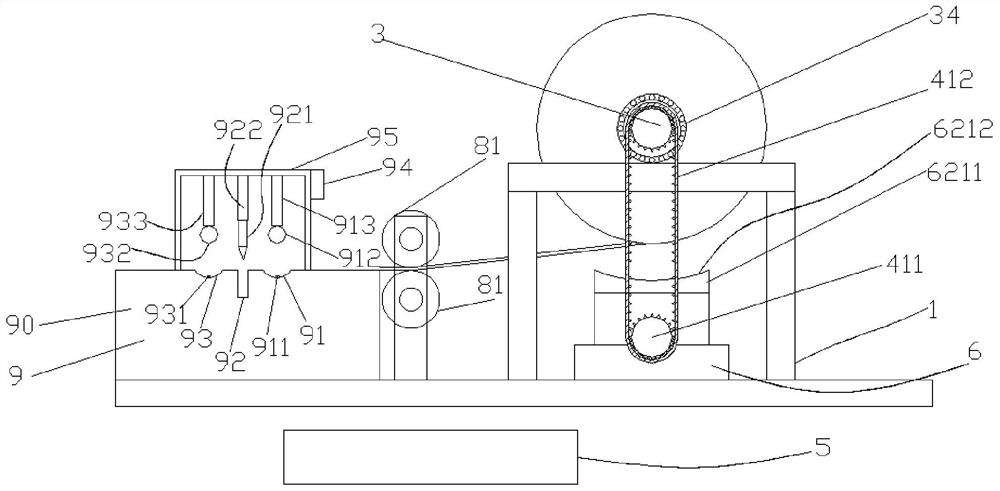

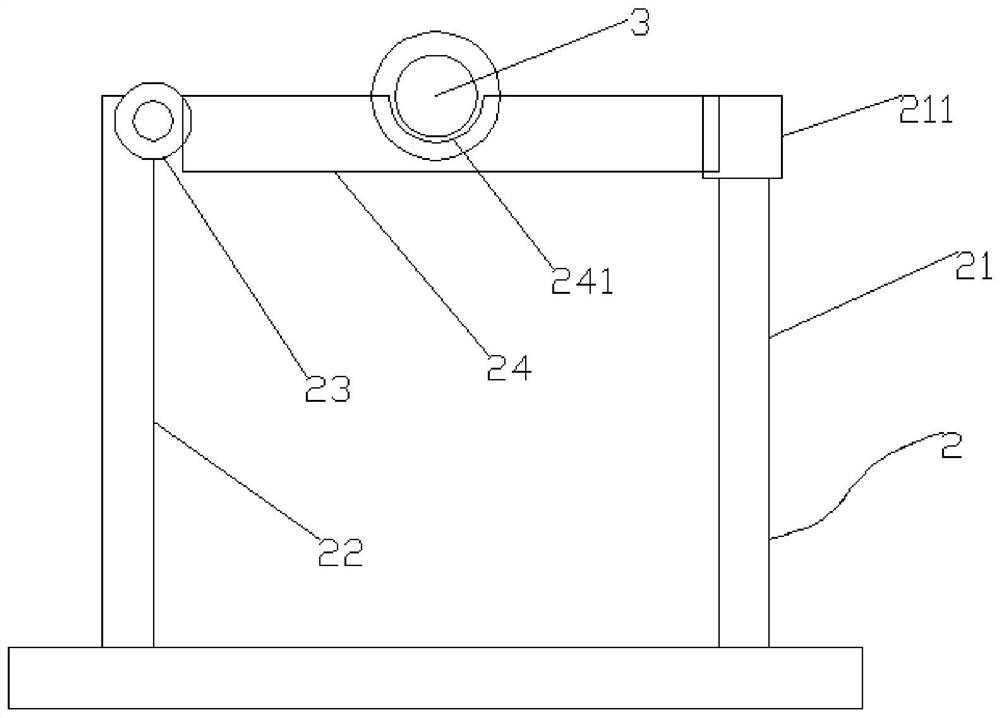

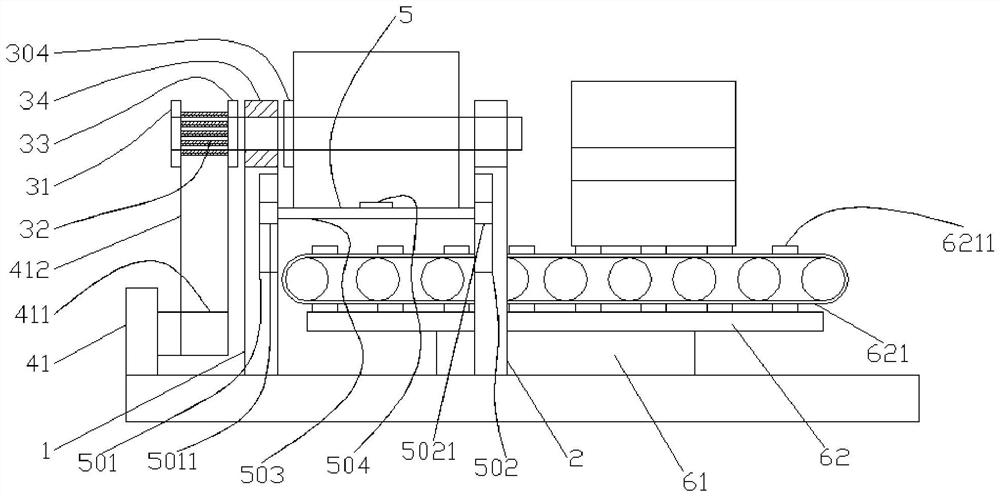

[0019] refer to figure 1 , figure 2 , image 3 and Figure 4, an intelligent and efficient roll paper unwinding and cutting machine of the present invention, comprising a first support 1, a second support 2, a first column 21, a first electric control fixture 211, a second column 22, an electric control shaft 23, a horizontal Rod 24, groove 241, first rotating shaft 3, round rod 31, first gear 32, first ring 33, bearing 34, first driving device 41, first driving wheel 411, first conveyor belt 412, intelligent control device 5, feeding device 6, and paper cutting device 9, the first support 1 is flat as a whole, the first support 1 is vertically arranged, and the second support 2 adapted to the first support 1 is provided directly behind the first support 1. The support 2 is mainly composed of the first column 21, the first electric control fixture 211, the second column 22, the electric control shaft 23, the cross bar 24, and the groove 241. The first column 21 and the sec...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com