Control method for automatic material receiving of truck

A control method and automatic technology, applied in the direction of conveyor control devices, loading/unloading, conveyor objects, etc., can solve the problems of large manual operation errors, time-consuming and labor-intensive, etc., to achieve a controllable solution, save labor costs, and reduce simple effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

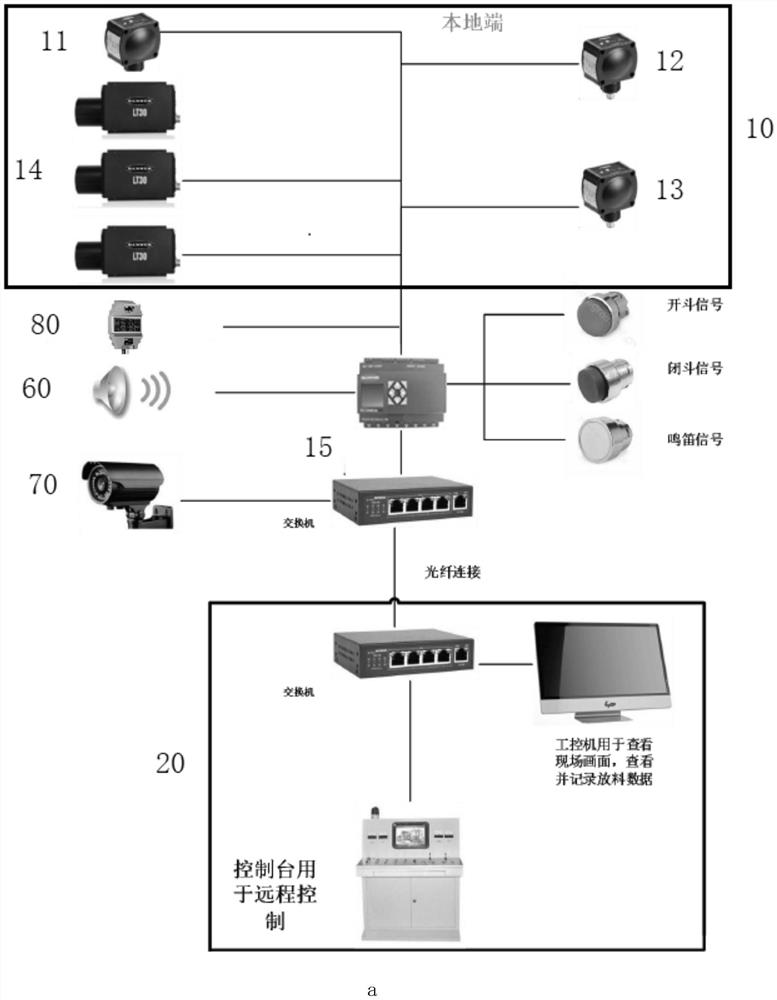

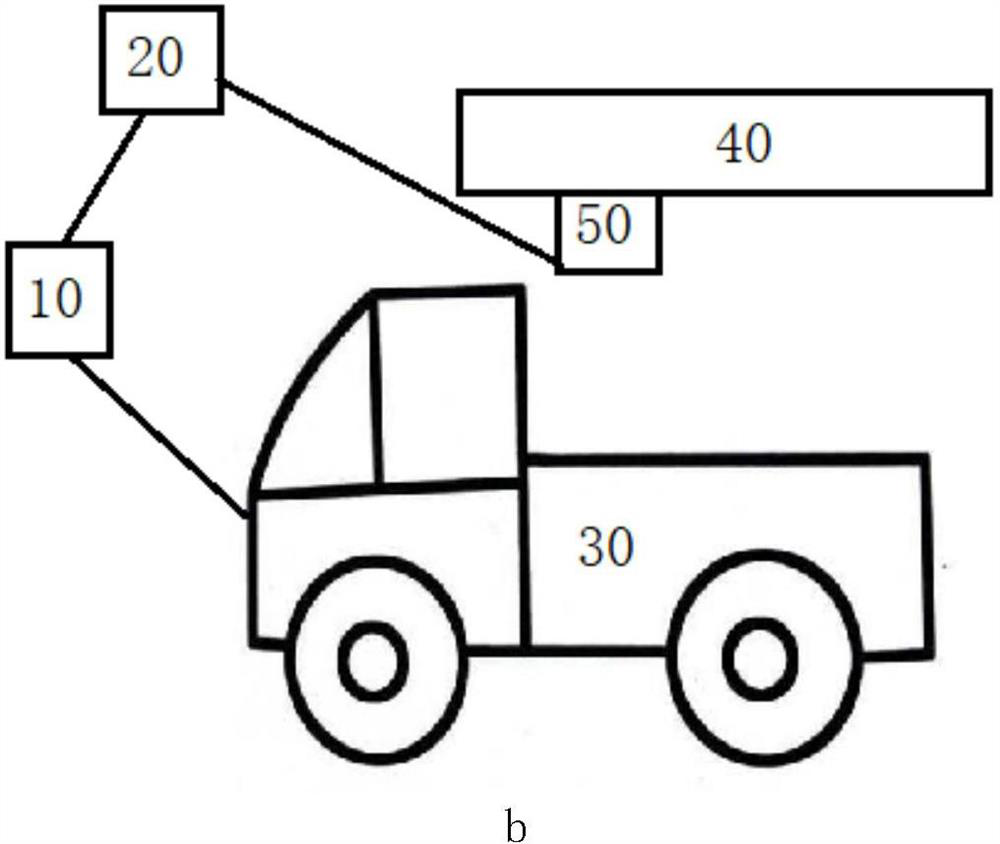

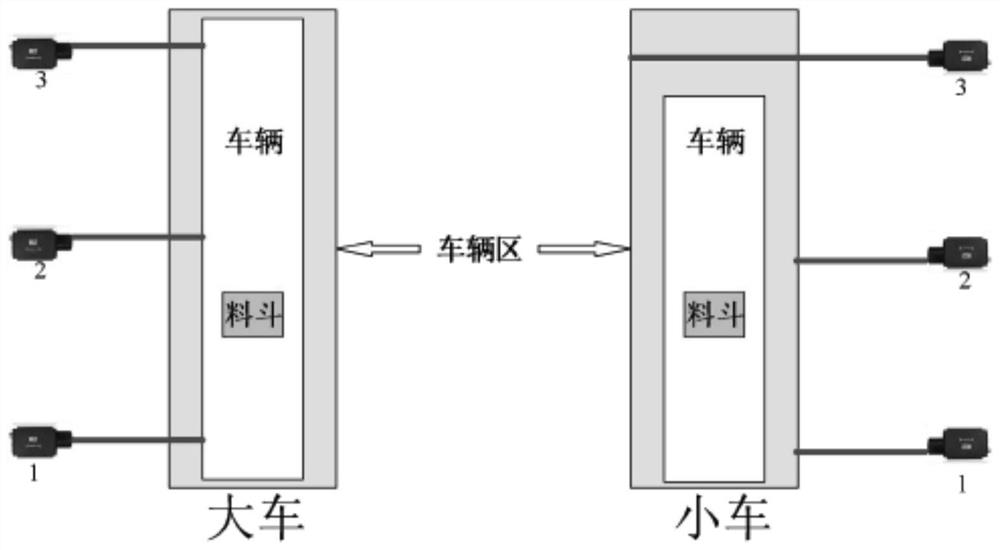

[0019] The present embodiment utilizes the control system of automatic material receiving of trucks to provide a control method for automatic material receiving of trucks, which includes the following steps, (1) using the laser range finder 14 to obtain vehicle type information, and to carry out vehicle type identification, which is convenient for the controller 20 to retrieve the threshold data; (2) utilize the first radar sensor 11 to obtain the position information of the vehicle 30, carry out vehicle position identification, ensure that the vehicle 30 covers the discharge position interval, and avoid material leakage; (3) utilize the second radar sensor 12 and / or the weight sensor 13 detects the material intake information in the vehicle 30, which is convenient for the controller 20 to retrieve the threshold data, (4) utilize the signal acquisition unit 10 and / or the controller 20 to judge the information obtained in steps (1)-(3) After meeting the requirements, the openi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com