Electric power fitting laser strengthening device and method

A technology of laser strengthening and electric fittings, which is applied in the field of electric fittings processing, can solve the problems of large volume of laser strengthening devices, low efficiency of strengthening methods, and high utilization rate of laser, and achieve simple structure, simple and convenient operation, and high utilization rate of laser Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

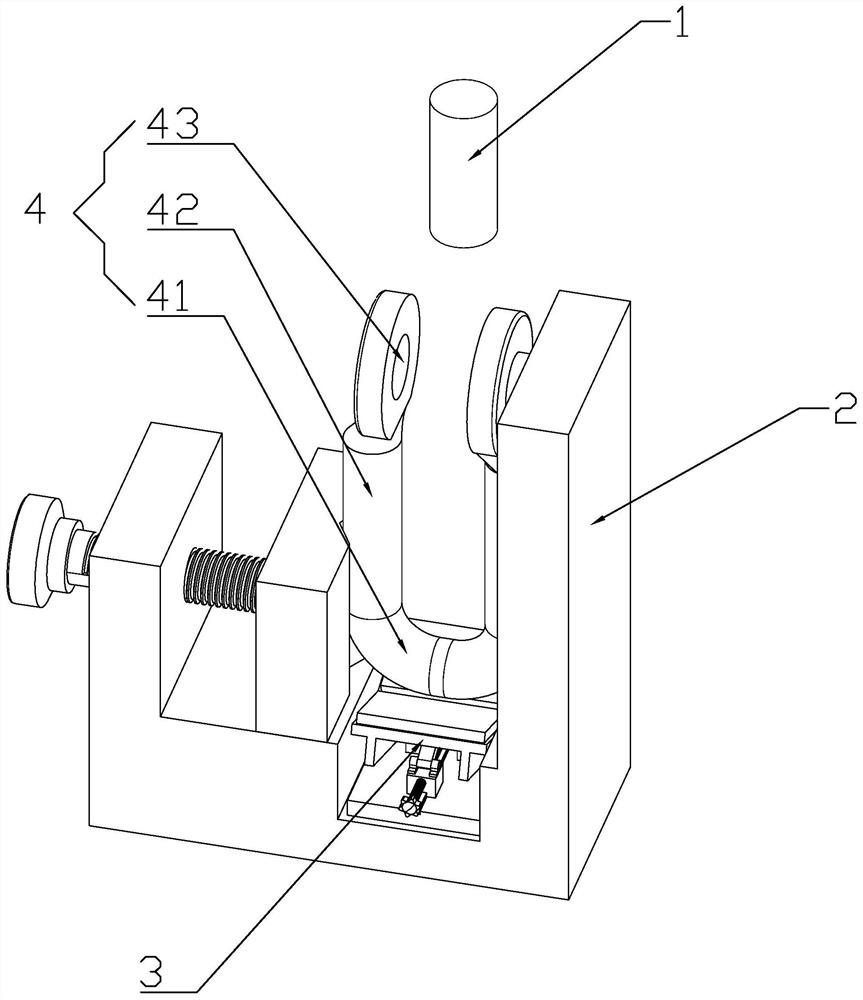

[0041] Such as figure 1 As shown, a laser strengthening device for electric power fittings is used for laser strengthening the U-shaped ring 4. The U-shaped ring 4 is a symmetrical structure, including an arc segment 41 at the bottom, and both ends of the arc segment 41 extend upward to form a vertical The vertical section 42 of the vertical section, the cross section of the arc section 41 and the vertical section 42 is circular, and the top of the vertical section 42 forms an ear upwards, and the ear is provided with a circular suspension hole 43, between the vertical sections 42 The circumferential direction of the arc section 41 is the area to be strengthened. Enhancements include:

[0042] The laser strengthening head 1 is arranged vertically downward, and is used to emit laser light to the strengthening area of the electric fitting;

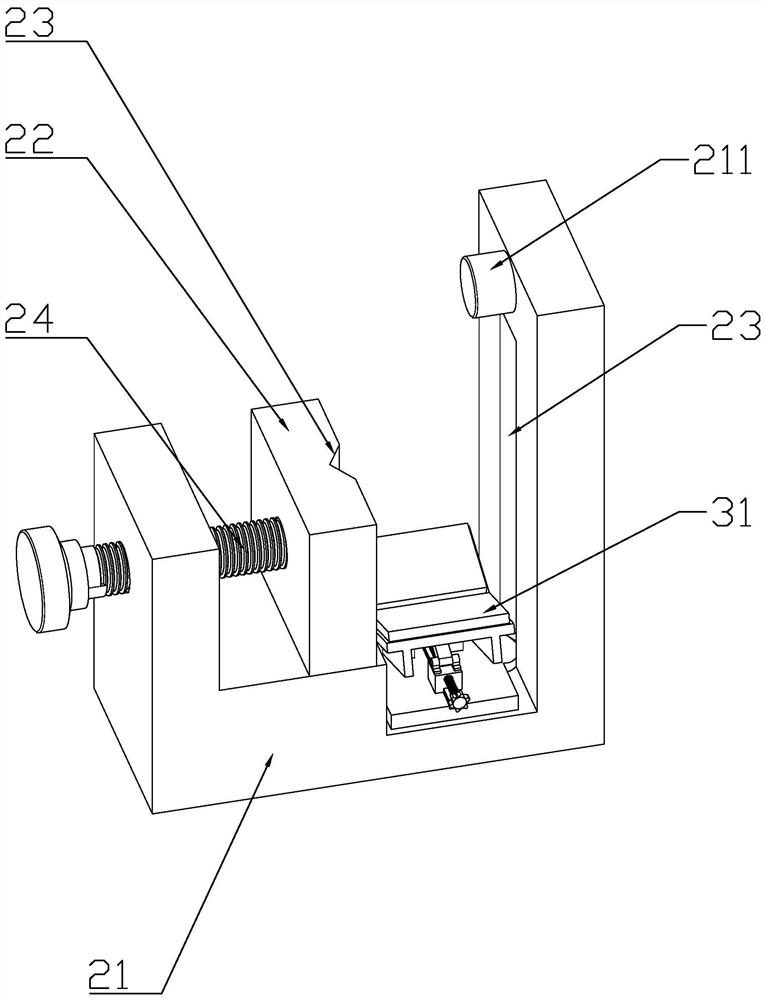

[0043] The clamping device 2 is used to fix and clamp the power fittings so that the laser can be directed to the strengthened area;

...

Embodiment 2

[0051] A laser strengthening method for electric metal fittings, comprising the steps of:

[0052] S1. Fix the U-shaped ring on the clamping device 2, in which the hanging hole 43 on one side is suspended on the limit boss 211 for Z-direction positioning, and the fixed screw 24 is rotated to move the slider 22 to clamp the U-shaped ring from both sides. Ring, the vertical section of the U-shaped ring is attached to the V-shaped grooves on both sides and the laser emitted by the laser strengthening head 1 is aimed at the strengthening area in the middle of the arc section, and the size of the laser spot is set. The long axis (perpendicular to The length of the horizontal axis of the arc segment) is twice the diameter of the arc segment, and the length of the minor axis (parallel to the horizontal axis of the arc segment) is the distance of the vertical segment 42;

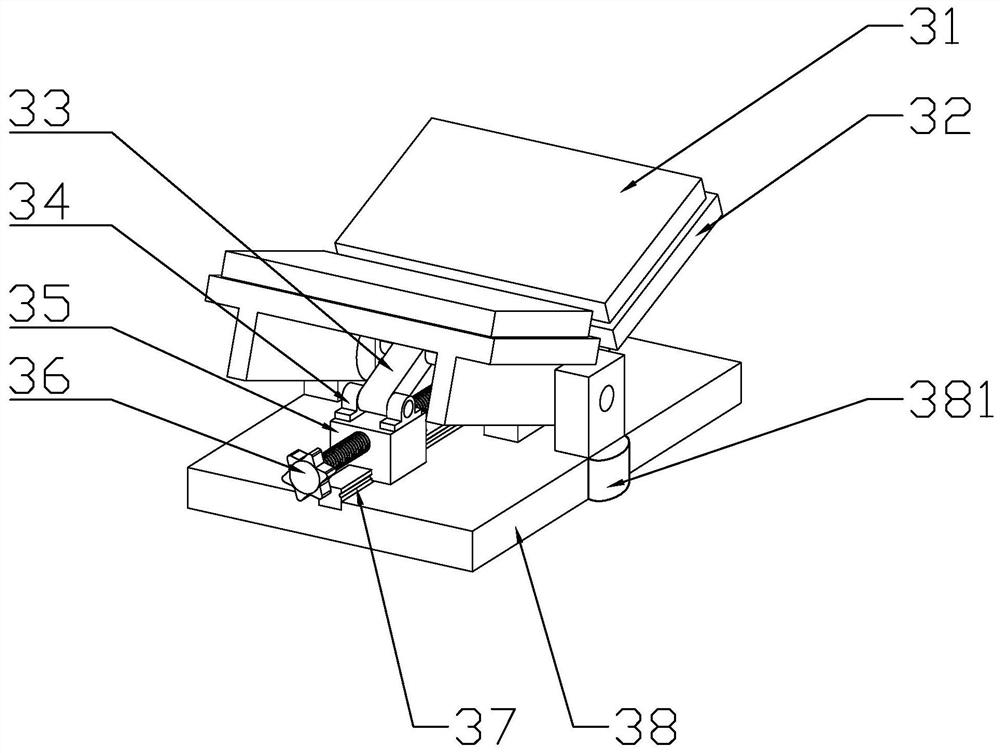

[0053] S2. Turn the ball screw 36 to adjust the position of the reflective surface of the reflector 3 to ensure t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com