Mineralization and Utilization of CO2 Exhaust Gas Ecological Protection Coal Mining Method

A coal mining method and protective technology, applied in the field of ecologically protective coal mining using CO2 waste gas in mineralization, to achieve the effect of preventing further development

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

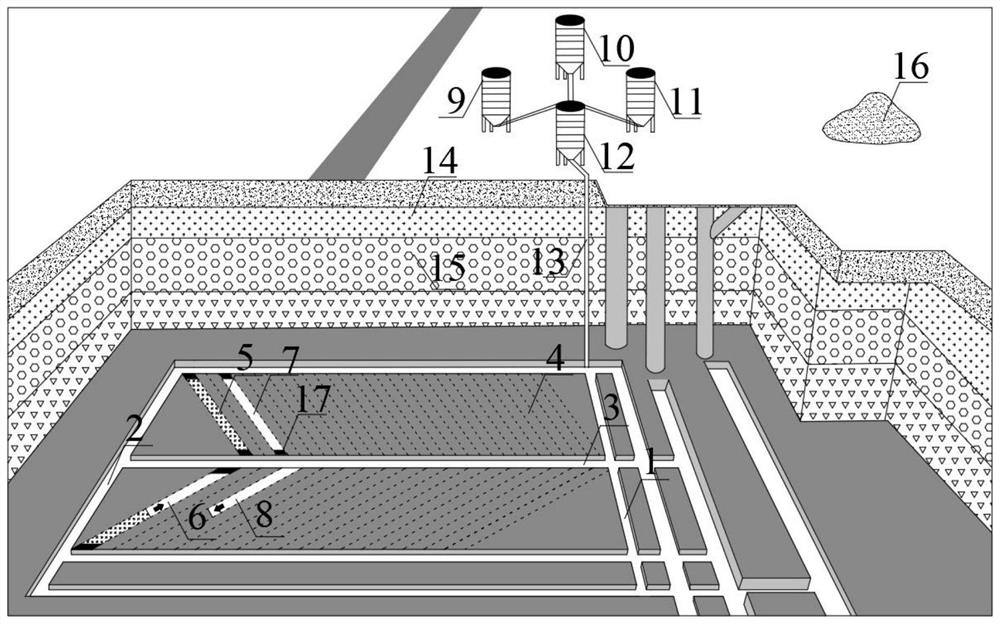

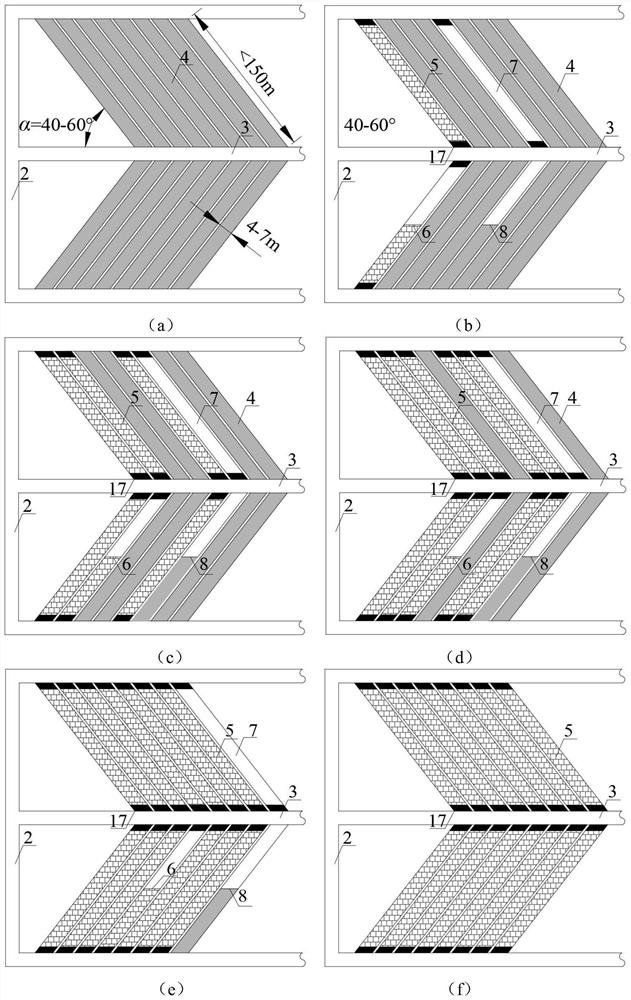

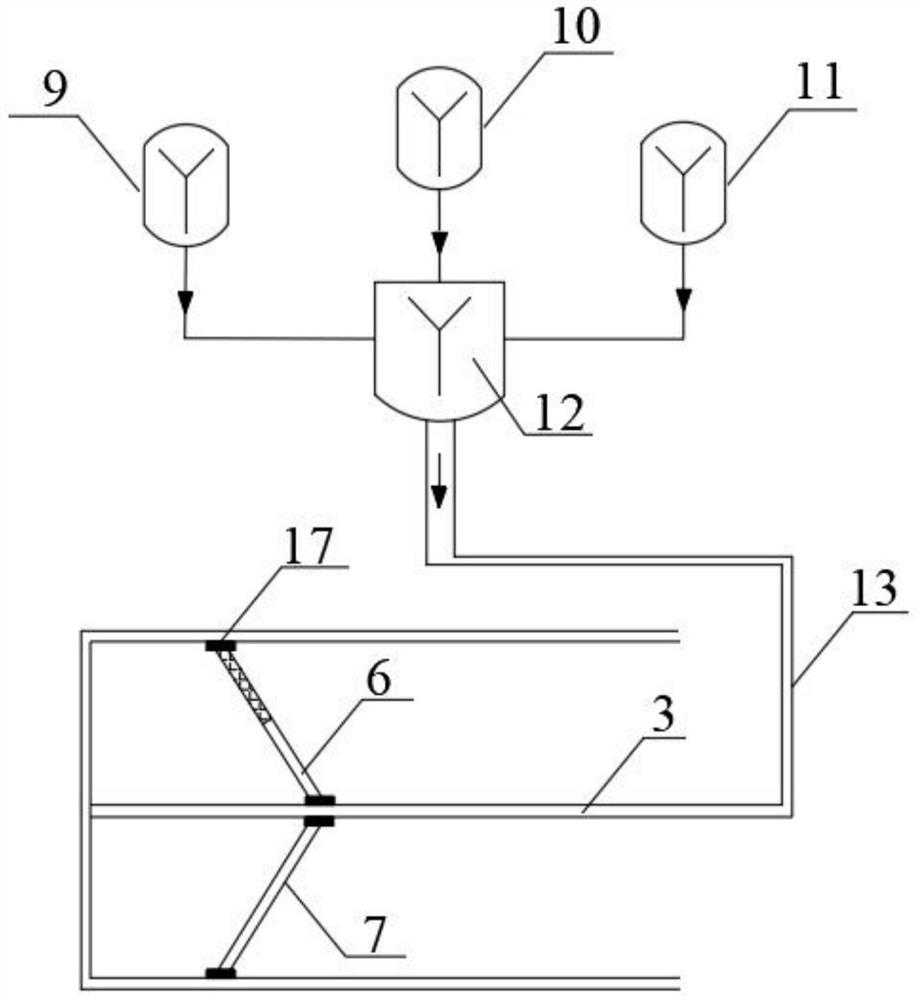

Embodiment 1

[0083] Embodiment 1: This example takes a certain mine in Shanxi as an example. The average buried depth of the coal seam is about 220m. The average block length is 330m, the average width is about 160m, and the reserves are about 200,000 tons. There are shallow aquifer water layer and surface 21 water above the mining area. The coal seam to be mined is No. XV coal with an average thickness of 2.4m and a dip angle of 1°-2°. The immediate roof is limestone with an average thickness of 8.5m and a unidirectional compressive strength of 54.0-213.0MPa. Coal seam No. IX also exists above No. XV coal (the bedrock section about 20m away from the immediate top of the limestone, mainly containing sandy mudstone, limestone, fine sandstone, mudstone, etc., and the lithology as a whole is moderately hard). About 24m above the No. Ⅸ coal seam, there is an effective water-resisting layer composed of sandy mudstone and mudstone (the bedrock section with an interval of about 20m in the middl...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com