An efficient ice melting system for wind turbine blades using latent heat of water

A technology for wind power blades and ice melting, which is applied to wind engines, wind power generation, and wind engines in the same direction as the wind. It can solve problems such as unfavorable heat preservation, energy waste, and long time consumption, and facilitate large-scale promotion and application. Wide range of working conditions and weak heat dissipation effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0029] The present invention will be further described in detail below with reference to the accompanying drawings and specific embodiments, so that the advantages and features of the present invention can be more easily understood by those skilled in the art, and the protection scope of the present invention can be more clearly defined.

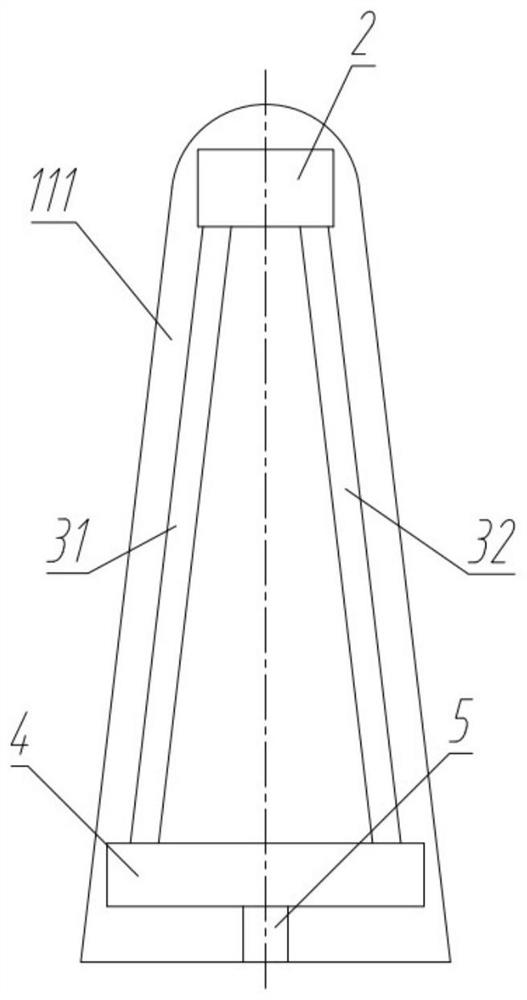

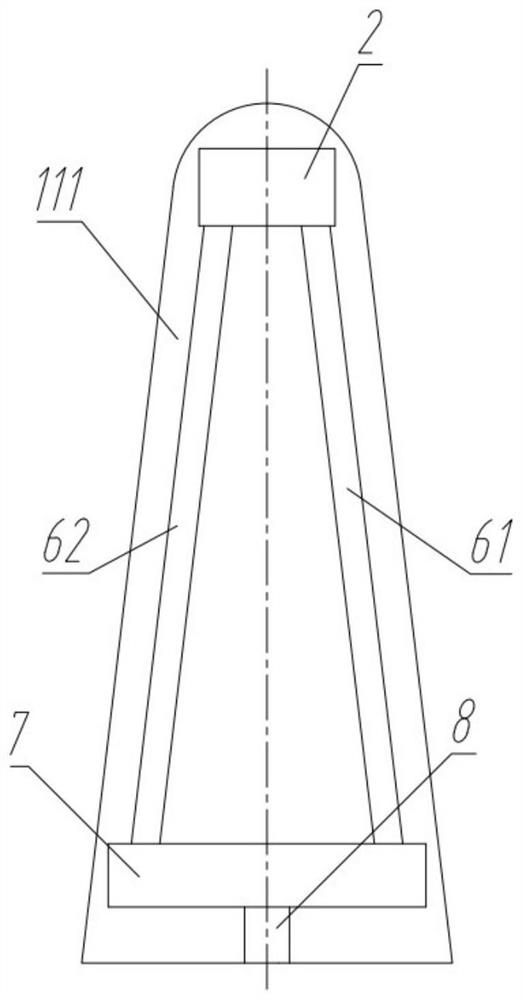

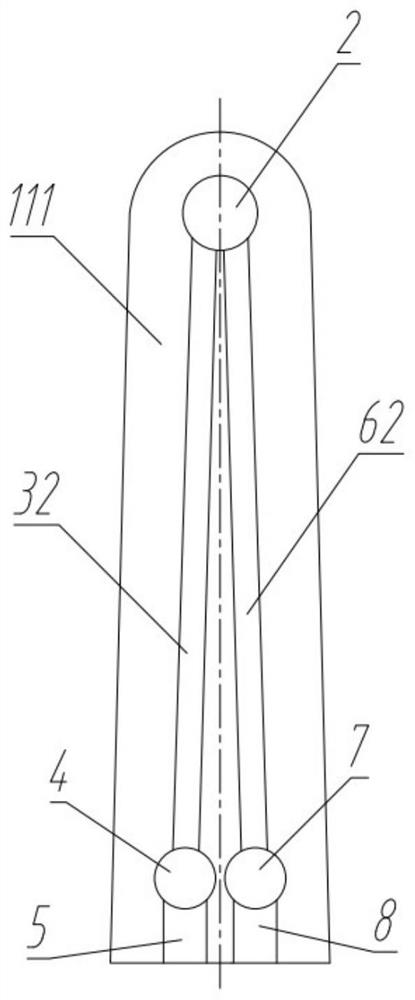

[0030] The present invention is a high-efficiency ice melting system for wind power blades utilizing latent heat of water, including wind power blades a111, wind power blades b222, wind power blades c333, tip header 2, return water ice melting pipe a31, return water ice melting pipe b32, Water header 4, blade return pipe 5, water ice melting pipe a61, water ice melting pipe b62, water header 7, blade water supply pipe 8, engine room 9, engine room return port 91, engine room water supply port 92, rotating sleeve 10, Water return port a101, water return port b102, water return port c103, water supply port a104, water supply port b105, water su...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com