Light-transmitting structure with special stone skin effect and manufacturing method thereof

A light-transmitting structure and manufacturing method technology, applied in the field of automotive interiors, can solve the problems of reducing the overall aesthetics of stone skin interiors, cracking and damage to the edges of embedded holes, and poor light transmission performance, so as to achieve a beautiful and comfortable use experience, The appearance is high-end and elegant, and the effect of improving strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

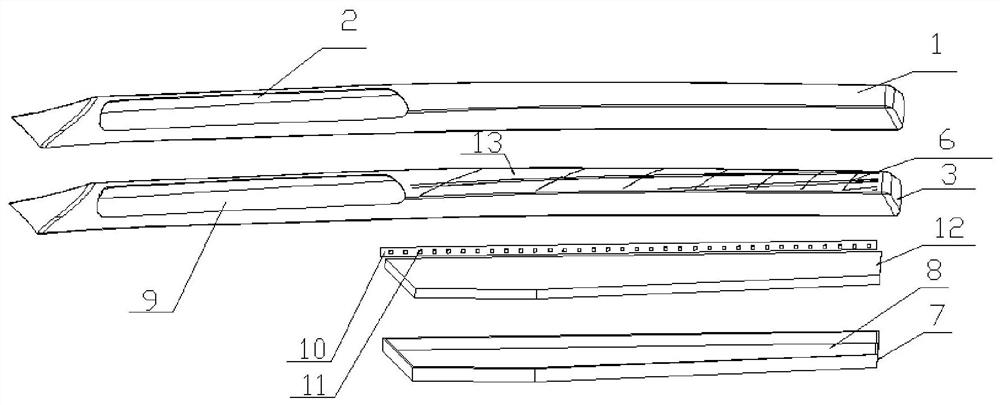

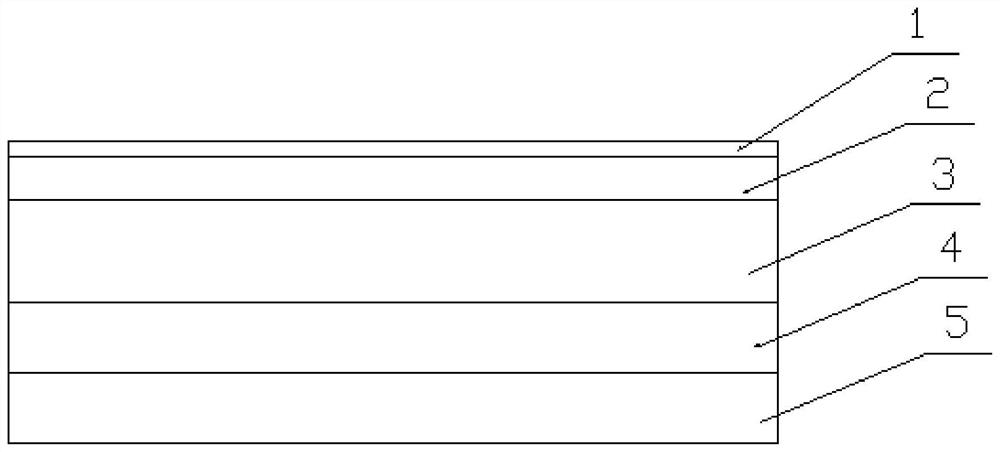

[0023] Embodiment: A stone skin special effect light-transmitting structure, including a stone skin layer 1, a light-transmitting soft rubber layer 2, a base layer 3, a backlight module 4 and an MCU main board 5, and the stone skin layer 1 is fixedly covered on the light-transmitting soft rubber layer 2 On one side surface, the other side of the light-transmitting soft rubber layer 2 is fixedly attached to the surface of the base layer 3. A light-transmitting area 6 is formed on the base layer 3. The backlight module 4 is fixedly installed on the other side of the base layer 3. The backlight module The planar light source formed by 4 can pass through the light-transmitting area 6 and the light-transmitting soft rubber layer 2 on the base layer 3 to finally transmit to the surface of the stone skin layer 1 to form a light-emitting area, and the backlight module 4 is electrically connected to the control circuit on the MCU motherboard 5 . The above-mentioned structure enables the...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com