Line laser-based complex heterogeneous product assembly parameter detection method and system

A heterogeneous product and parameter detection technology, which is applied in the field of laser measurement, can solve the problems of high-precision and contact measurement of the center of the angular spherical surface, and achieve high measurement efficiency.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

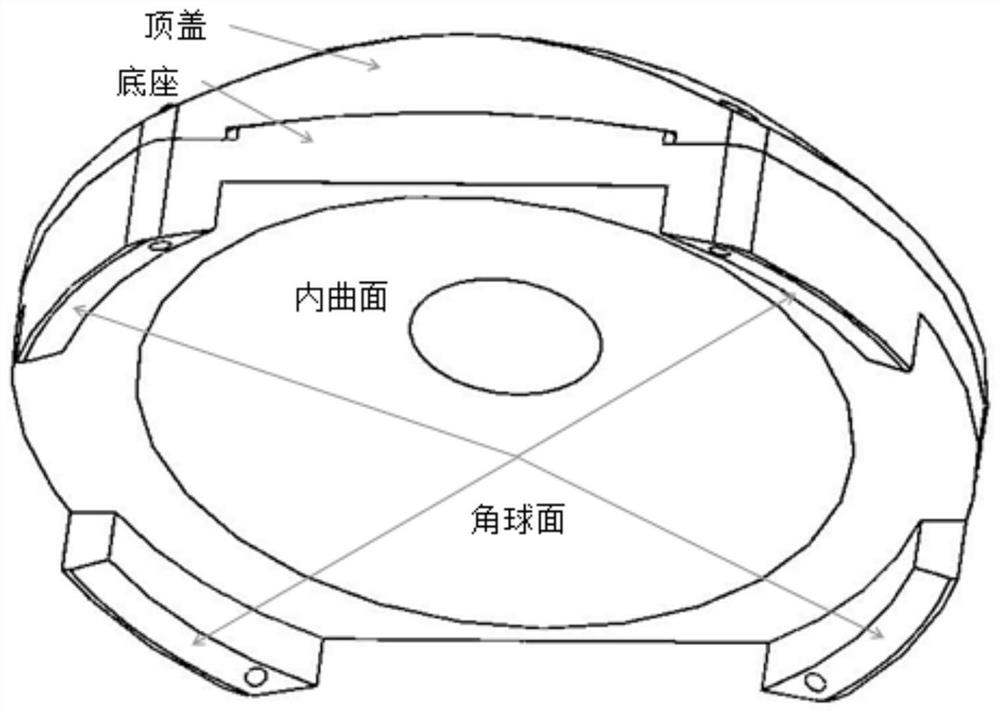

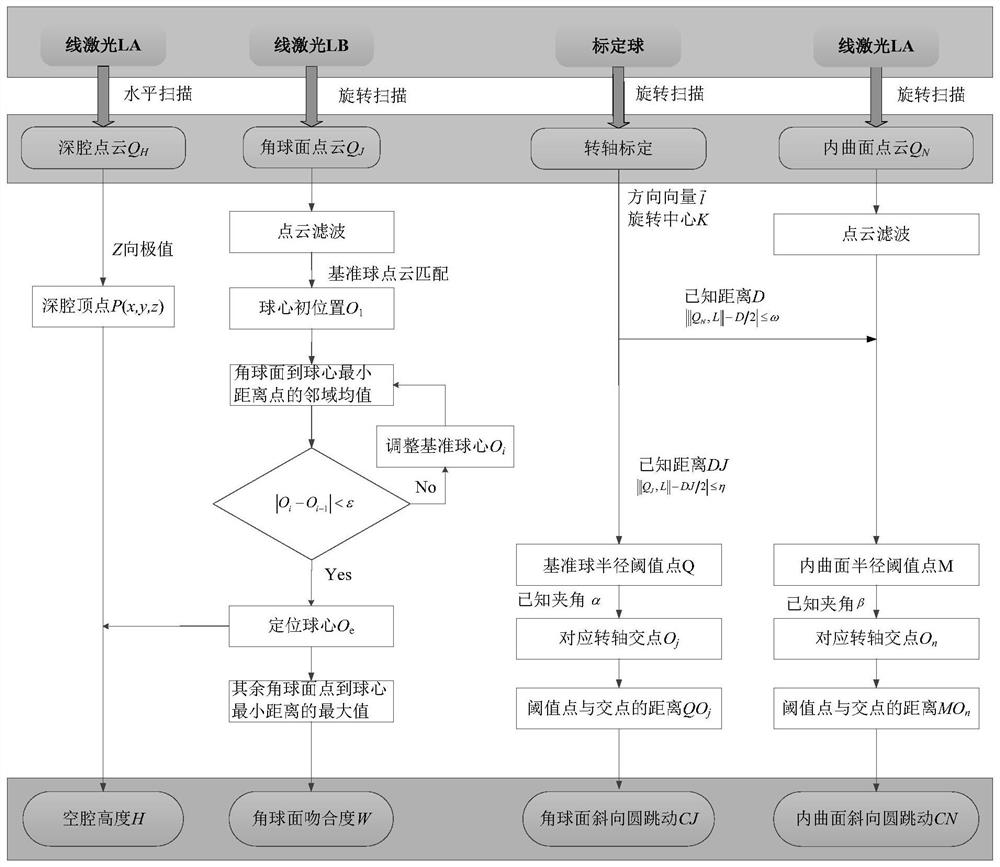

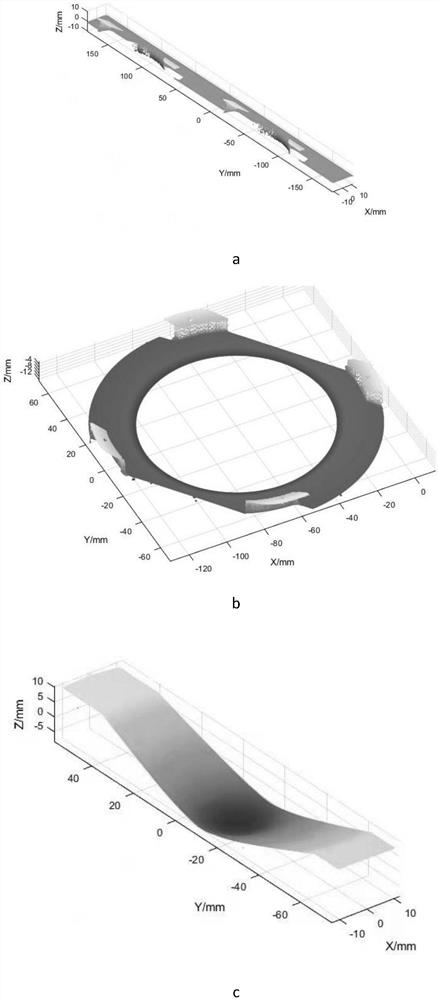

[0056] Embodiment 1: A method for detecting assembly parameters of complex heterogeneous products based on line lasers, such as figure 1 and figure 2 As shown, the complex heterogeneous product is a corner part assembled with a corner base and a top cover.

[0057] 1. Shaft calibration based on a single standard sphere

[0058] Place the high-precision diffuse reflective ceramic standard ball on the turntable, and use the line laser to scan the standard ball with light stripes to obtain the direction vector of the rotating shaft and the center point of rotation.

[0059] The calculation process of the direction vector and the rotation center point of the rotation axis is as follows:

[0060] S101: Perform least squares ellipse fitting on each light strip on the standard sphere to obtain the corresponding initial circle center position.

[0061] S102: Carry out least squares ellipse fitting on the initial center position again, and obtain the final center position as the ro...

Embodiment 2

[0100] Embodiment 2: A complex heterogeneous product assembly parameter detection system based on line laser, such as figure 1 and Figure 5 As shown, the complex heterogeneous product is a corner component equipped with a corner base and a top cover, including a scanning module, a data conversion module, a data segmentation module, a first computing module, and a second computing module.

[0101] The scanning module is used to place the high-precision diffuse reflection ceramic standard ball on the turntable, and use the line laser to scan the standard ball with light stripes to obtain the direction vector of the rotating shaft and the center point of rotation. The data conversion module is used to translate and scan the bottom curved surface area of complex heterogeneous products and rotate and scan the angular spherical surface and inner curved surface to obtain the corresponding light strip data, and perform Cartesian coordinate conversion according to the obtained rotat...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com