Production process of wool felt cap

A production process and wool technology, applied in the field of clothing and apparel production, can solve the problems of lack of fluffy and comfortable hand feeling, and achieve the effects of not easy to deform, comfortable to touch, and good antistatic effect.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

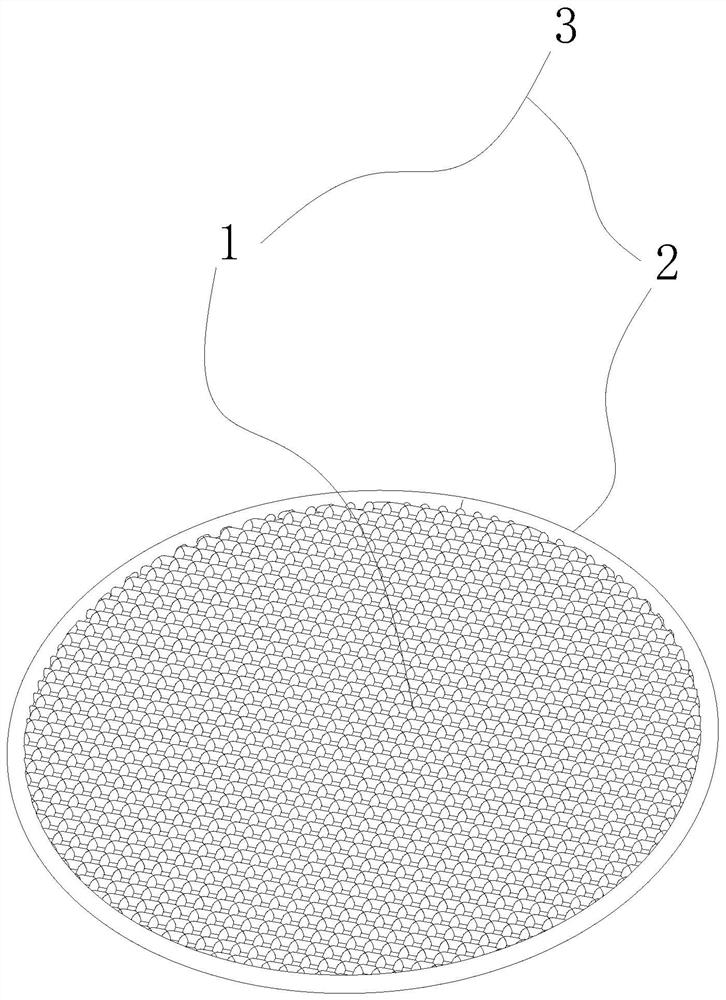

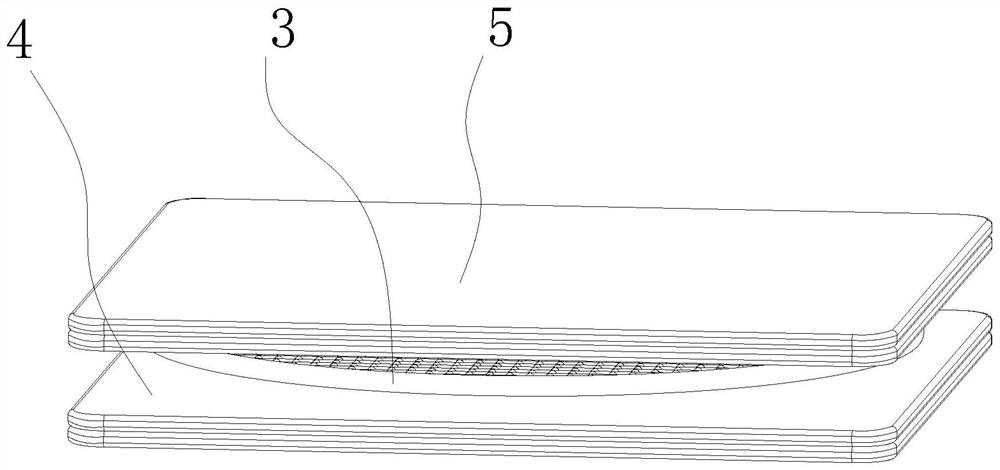

[0032] A kind of wool felt hat production technology, comprises the following steps,

[0033] Step 1, the same amount of wool fiber and antistatic fiber are sent into the mixing box (cotton mixer) for mixing, the antistatic fiber is antistatic polyester, and the mixed fiber mass is obtained by using the cotton mixing box (cotton mixer), The cotton mixing box is such as the DP518 cotton mixing machine of the Xinheng Nonwoven brand.

[0034] Step 2: send the mixed fiber group 1 into the opener for fluffing treatment by artificial means, keep the mixed fiber group 1 in a relatively fluffy state, and then take it out.

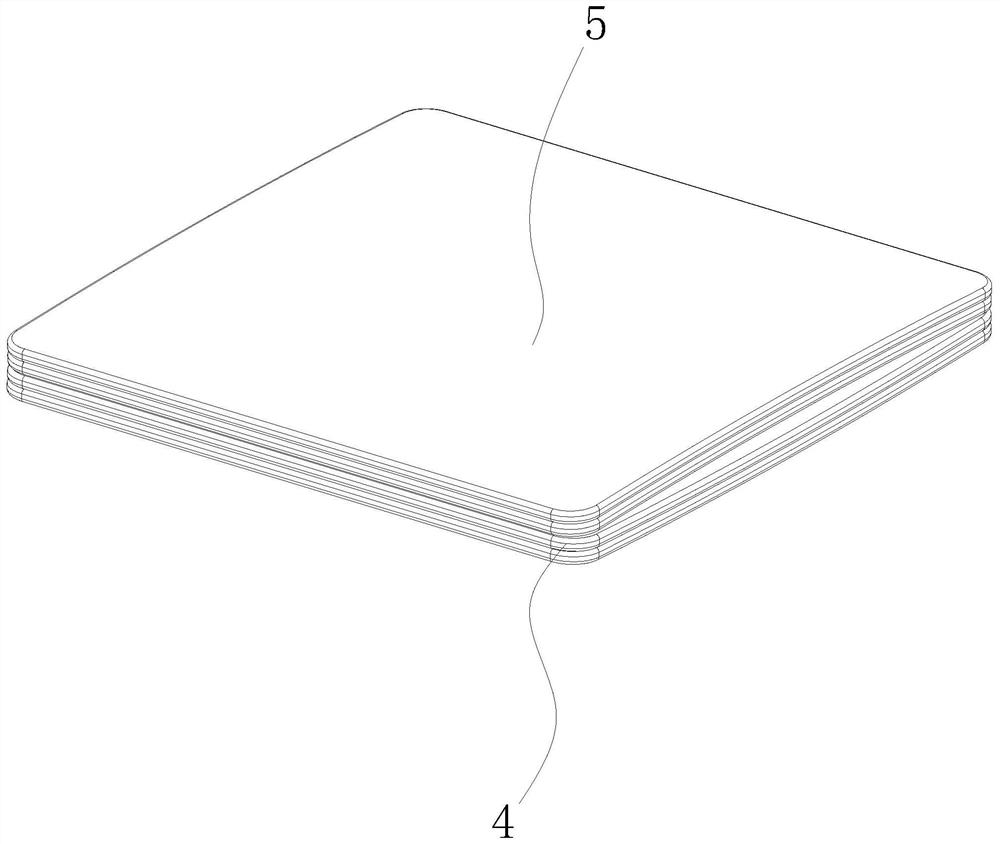

[0035] Step 3: send the mixed fiber mass into the needling machine for inner felting treatment in an artificial way to obtain the inner layer 4, wherein the needling machine is an ordinary needling machine, such as CL-ZCJ001 of Chuanglong Nonwoven Machinery brand Model needle loom.

[0036] Step 4, the wool fiber is sent into the mixing box and mixed, the total a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com