Butyl waterproof roll production line

A waterproofing membrane and production line technology, applied in the direction of flat products, household appliances, other household appliances, etc., can solve problems such as time-consuming, coordinated adjustment, affecting production progress, etc., to ensure continuity, ensure convenience, and improve production. The effect of efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

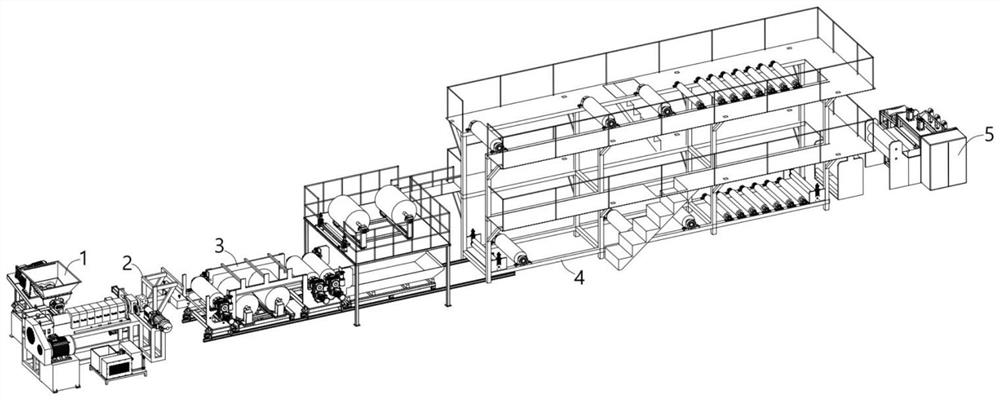

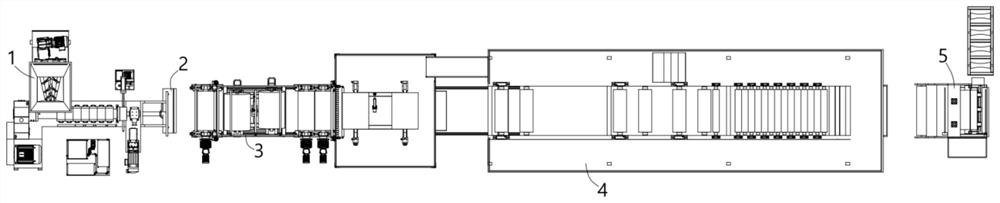

[0024] A butyl waterproof coil production line, including a cone double feeding mechanism 1, a screw extrusion mechanism 2, a film cooling mechanism 3, a coil buffer frame 4 and a winding mechanism 5, and the discharge end of the cone double feeding mechanism 1. It is communicated with the feed end of the screw extrusion mechanism 2, the discharge end of the screw extrusion mechanism 2 is butted with the active roller of the lamination cooling mechanism 3, the discharge end of the lamination cooling mechanism 3 is docked with the coil buffer frame 4, and the roll The end of the material buffer rack 4 is docked with the winding mechanism 5;

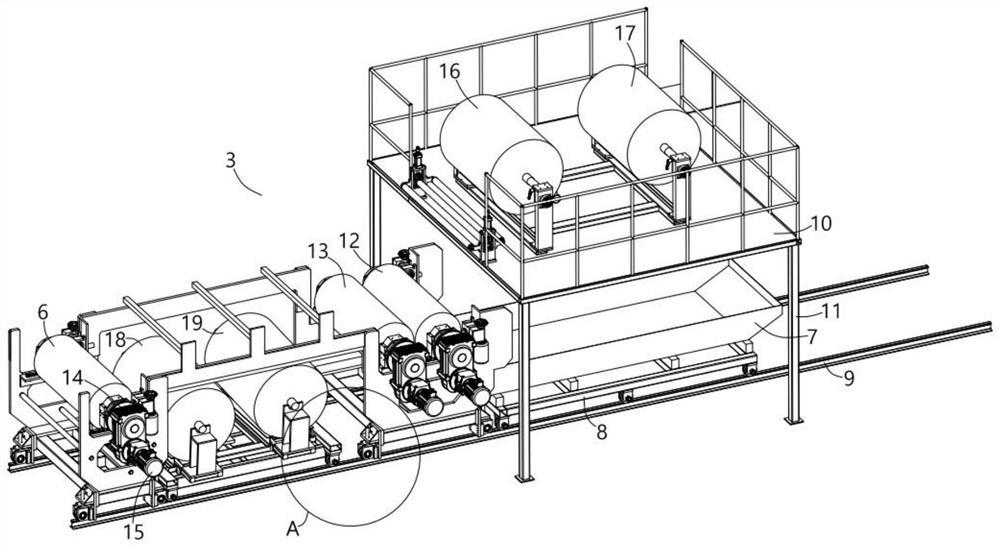

[0025] The lamination cooling mechanism 3 includes a driving roll 6, an upper laminating roll, a pressing roll, a lower laminating roll and a cooling tank 7, and the driving roll 6, the lower laminating roll, the pressing roll and the cooling tank 7 are all arranged on the translation frame 8, The translation frame 8 makes a translational ...

Embodiment 2

[0028] In this embodiment, the pressure roller includes a movable pressure roller 12 and a fixed pressure roller 13, and the axes of the driving roller 6, the movable pressure roller 12 and the fixed pressure roller 13 are all fixedly connected to their respective reduction gear mechanisms 14. The reduction gear mechanism The power input end of 14 is fixedly installed with a drive motor 15. The movable pressure roller 12, the fixed pressure roller 13 and the driving roller 6 are all driven by their respective drive motors 15. The movable pressure roller 12 and the fixed pressure roller 13 keep moving intermittently. While one rotates, the other remains fixed, and in this way the film-coated roll is extruded.

Embodiment 3

[0030] In this embodiment, the upper laminating roll includes an upper working roll 16 and an upper backup roll 17 , the lower laminating roll includes a lower working roll 18 and a lower spare roll 19 , the upper working roll 16 and the upper spare roll 17 , and the lower working roll 18 It operates alternately with the lower backup roller 19. With this arrangement, when the film-coated roll is exhausted, it can be quickly replenished by the backup roller, thereby ensuring the continuity of production and greatly improving the production efficiency.

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap