River channel dredging ship

A technology for dredging ships and river channels, applied in fixed filter element filters, mechanically driven excavators/dredgers, applications, etc., can solve problems such as cutting underwater aquatic plants and other entanglements, and achieve self-cleaning ability. The effect of improving efficiency and reducing workload

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

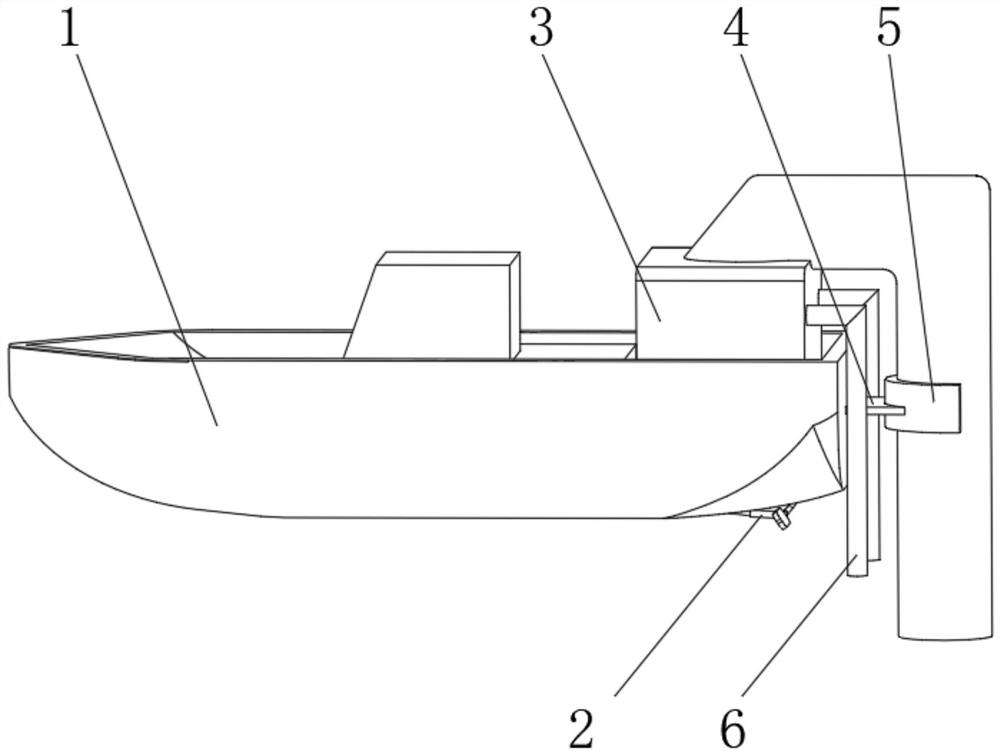

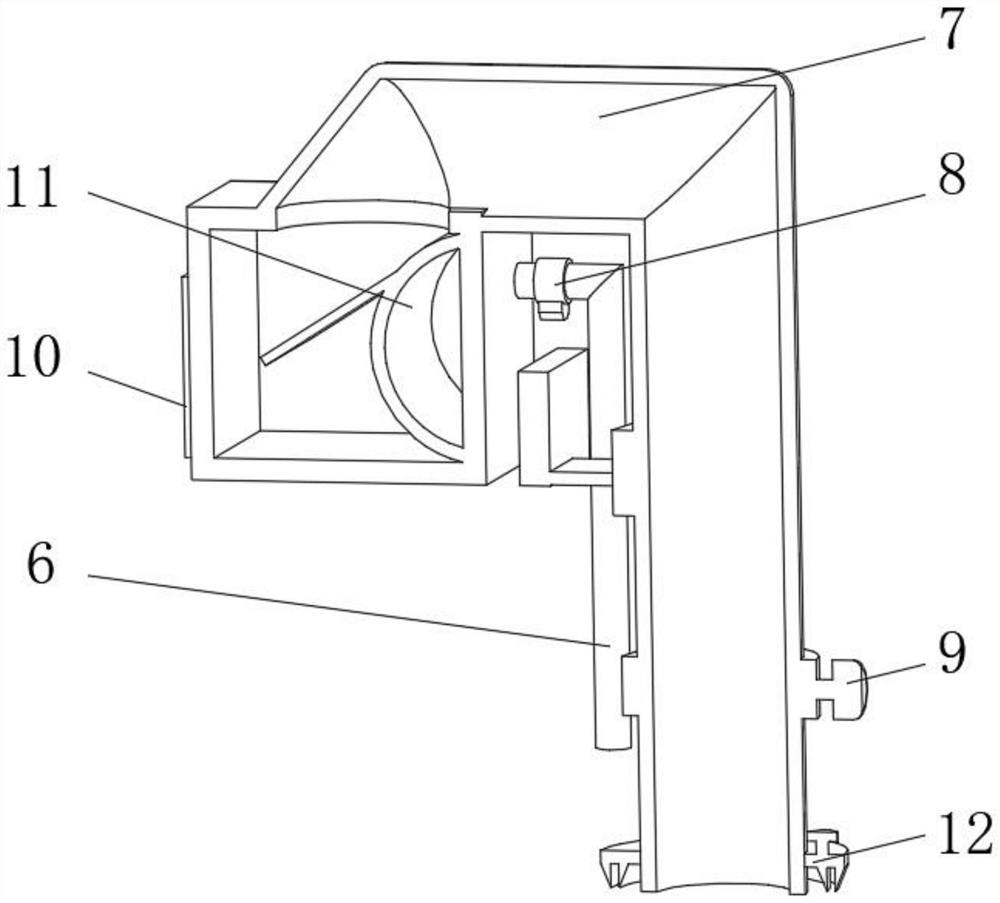

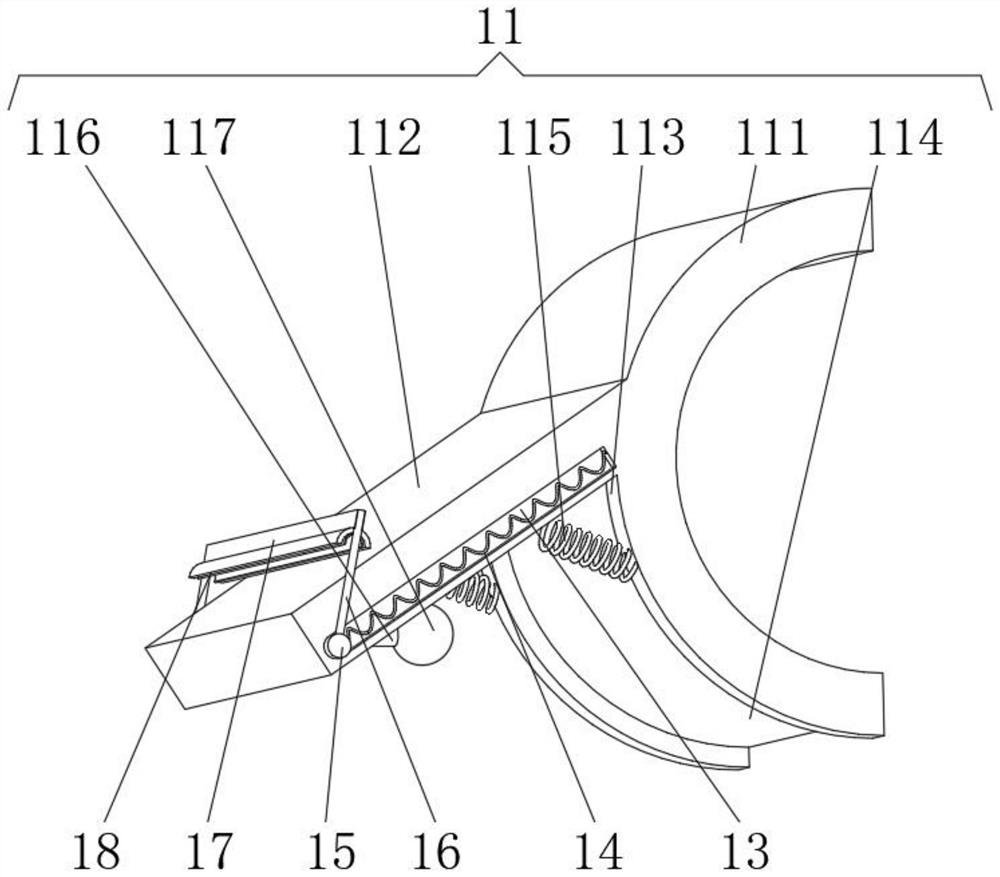

[0027] see Figure 1-3 , the present invention provides a technical solution: a river dredging ship, comprising a hull 1, a driving propeller 2 is installed at the bottom of the hull 1, a collection frame 3 is fixedly connected to the inner side of the hull 1, and a fixing plate is fixedly connected to the outer side of the hull 1 4. The side of the fixed plate 4 far away from the hull 1 is fixedly connected with an arc-shaped stop clamp 5, the side of the collection frame 3 close to the fixed plate 4 is connected with a water outlet pipe 6, and the top of the collection frame 3 is connected with a feed pipe 7, A suction pump 8 is installed on the outside of the outlet pipe 6 close to the collecting frame 3, a dredging pump 9 is installed on the outside of the feed pipe 7 away from the collecting frame 3, and a retrieving pump is installed on the side of the collecting frame 3 away from the outlet pipe 6. Door 10, filter device 11 is installed on the inner wall of collection f...

Embodiment 2

[0034] see Figure 1-5 , the present invention provides a technical solution: on the basis of Embodiment 1, a crushing device 12 is installed near the position of the dredging pump 9 on the outside of the feed pipe 7, the crushing device 12 includes a rotating motor 121, and the output shaft of the rotating motor 121 Rotationally connected with a rotating rod 122, the end of the rotating rod 122 away from the rotating motor 121 is fixedly connected with a circular plate 123, one side of the circular plate 123 is provided with a groove 124, and the inner wall of the groove 124 is evenly equipped with elastic columns 125, the elastic force An arc-shaped push plate 126 is fixedly connected to an end of the post 125 away from the groove 124 .

[0035] A base plate 19 is evenly installed on the side of the circular plate 123 away from the rotating rod 122, and a cylinder 20 is fixedly connected to the side of the base plate 19 away from the circular plate 123. The outer side of the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com