A device for moving and loading trays of an automatic chip inserter

A technology of a transfer device and a wafer inserter, which is applied in the directions of transportation and packaging, conveyor objects, and final product manufacturing, etc., can solve the problems of cumbersome, lack of omnidirectional adjustment function, and the deviation of the silicon wafer from the silicon wafer support device.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0038] The following will clearly and completely describe the technical solutions in the embodiments of the present invention with reference to the accompanying drawings in the embodiments of the present invention. Obviously, the described embodiments are only some, not all, embodiments of the present invention.

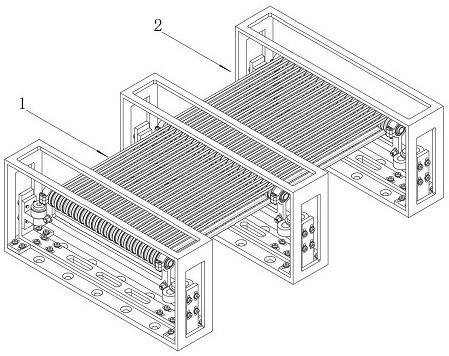

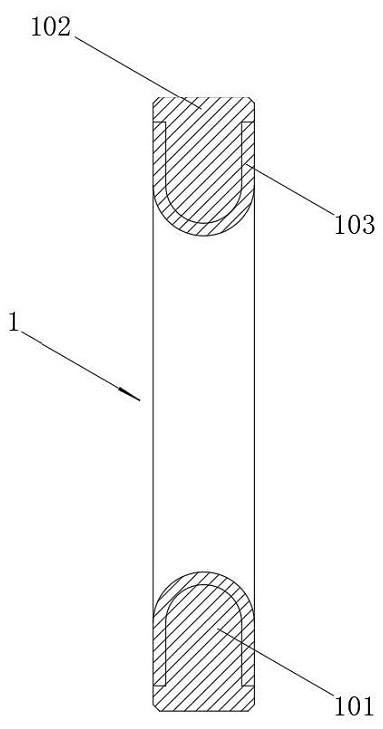

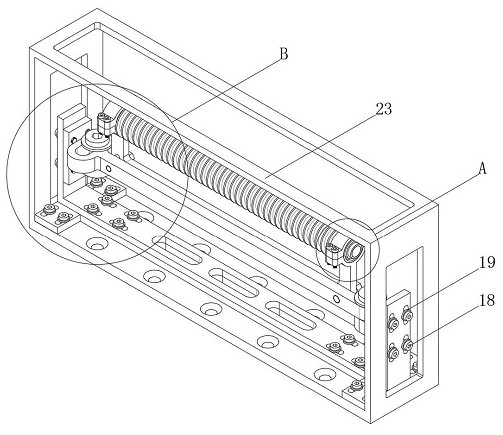

[0039] refer to Figure 1-Figure 7, an automatic chip inserting machine transfer pallet device, including several transfer devices 2 and the transfer bar 1 connected to it, the transfer bar 1 is a multi-layer structure, the transfer bar 1 includes a bar main body 101, the bar main body The outer side of 101 is the contact portion 102, and the inner side of the bar main body 101 is a wear-resistant layer 103. The wear-resistant layer 103 needs to be in contact with the rotating grooved roller 5. Therefore, good wear resistance is required to ensure the service life. The bar main body 101 and the contact portion 102 The material is the same, all are soft silica gel. Wh...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com