Online follow-up intelligent gluing machine for gift boxes

A gluing machine and follow-up technology, applied in the field of gluing, can solve the problems of not being able to meet the needs of replacement, reduce work efficiency, etc., and achieve the effect of convenient adjustment, fast speed, and convenient parameter change

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

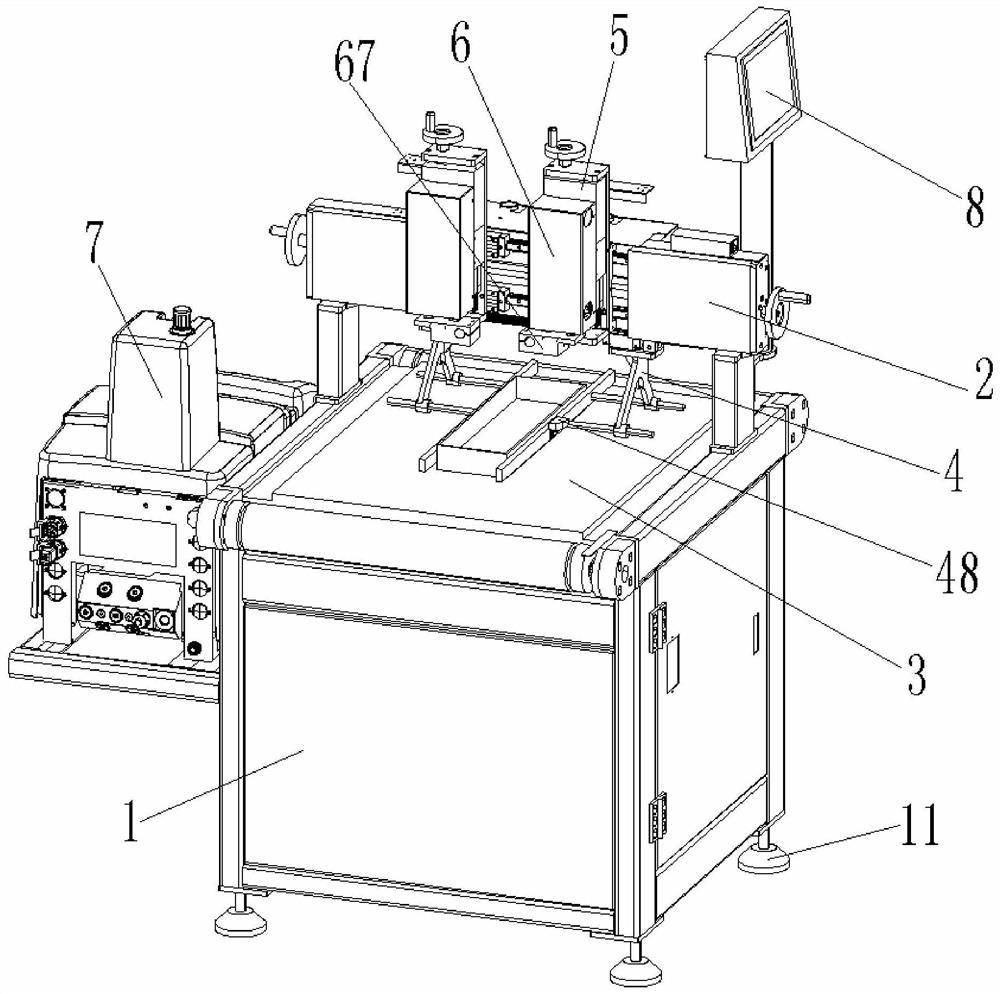

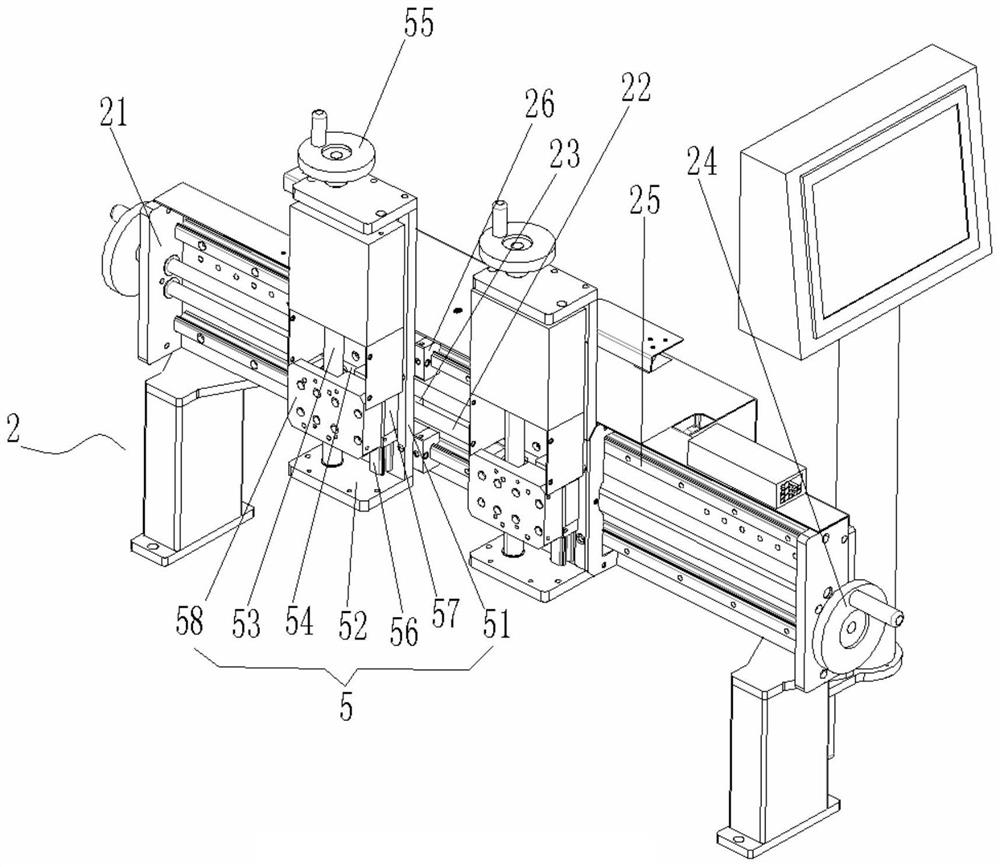

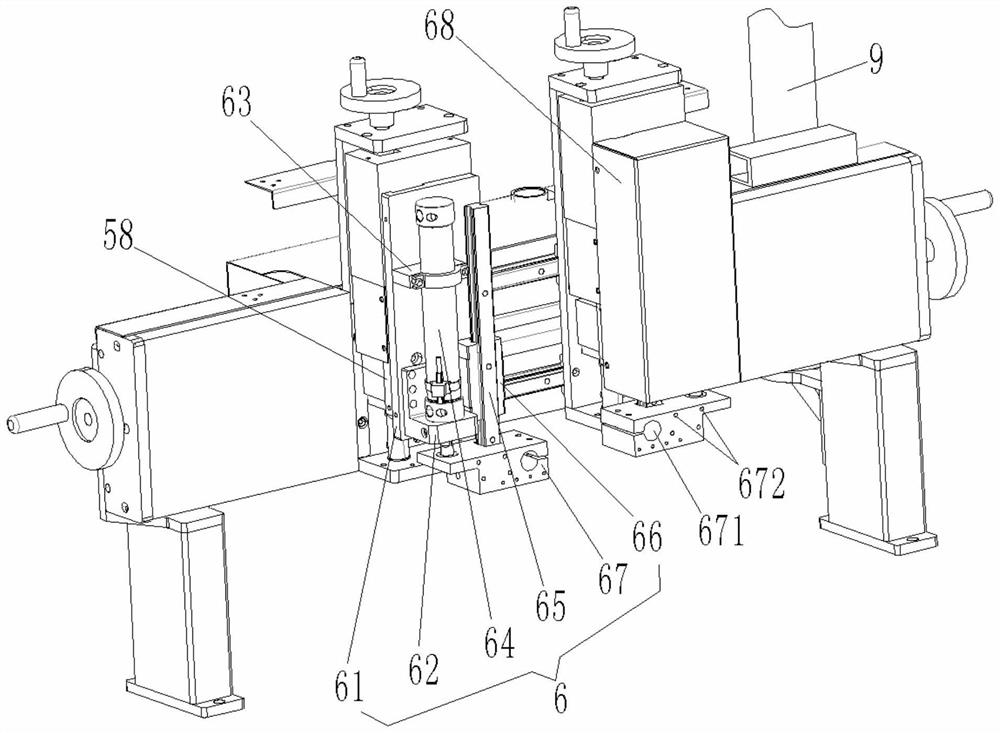

[0033] see Figure 1 to Figure 6 , the present invention provides an online follow-up intelligent gluing machine for gift boxes, which includes a case 1, a controller 7 for controlling the gluing process is provided on one side of the case 1, wherein a longitudinal belt conveyer is installed on the upper end of the case 1 machine 3, the top of the belt conveyor 3 is provided with a transverse beam 2, the transverse beam 2 is fixed on the cabinet 1 through vertical legs, and the front end of the transverse beam 2 is provided with two groups of first vertical mechanisms 5 capable of lateral movement, and the first A vertical mechanism 5 is provided with a second vertical mechanism 6 capable of vertical movement; the lower end of the second vertical mechanism 6 is provided with a vertically movable mounting plate 67, where the mounting plate 67 is provided with mounting holes A671 And installation hole B672, installation hole A671 is used for fixed installation of hot glue gun as...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com