Shroud ring linear cutting machining method

A processing method and wire cutting technology, applied in the direction of electric processing equipment, metal processing equipment, metal processing machinery parts, etc., can solve the problems of rough cutting surface, cumbersome processing, and adverse effects on the physical and chemical properties of metal materials, and achieve low processing cost, Fast positioning and less burr effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

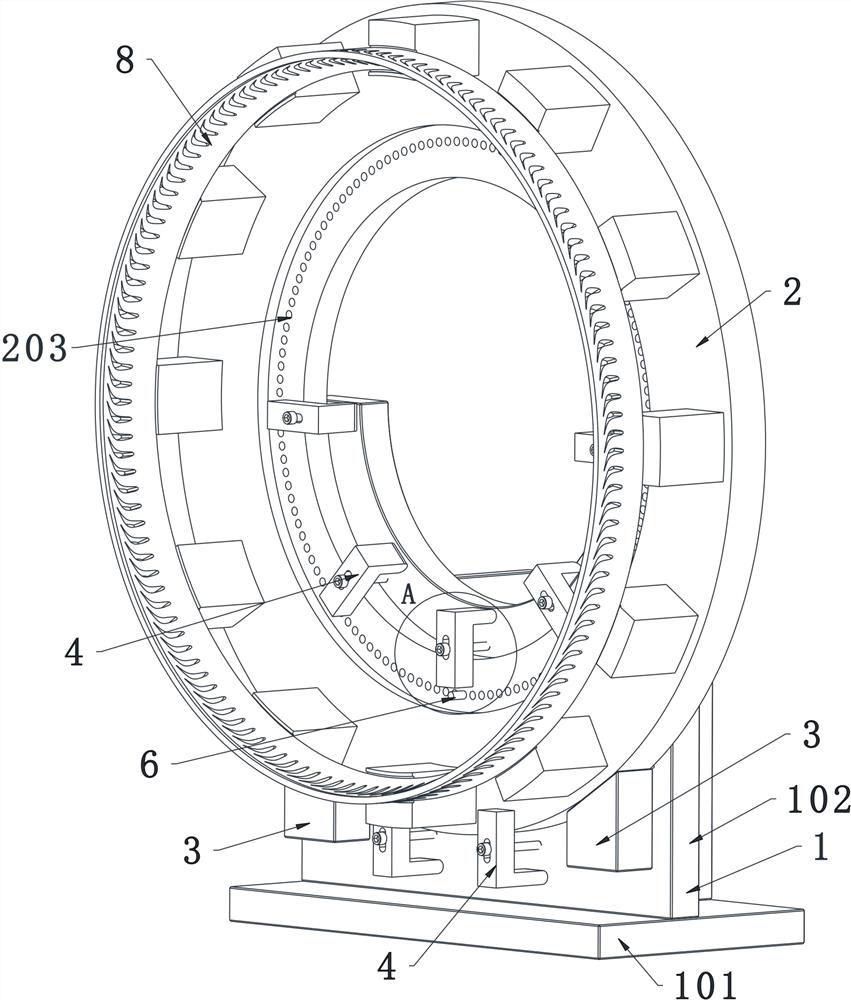

[0041] A kind of shroud line cutting processing method, it is carried out based on shroud processing positioning tooling, and its steps comprise:

[0042] S1, welding the shroud to be processed on the workpiece mounting ring 2 to form the workpiece mounting ring 2 as a whole;

[0043] S2 , drilling the indexing holes 203 and the shroud threading holes on the entire workpiece mounting ring 2 to obtain the whole pre-processed shroud fixed on the workpiece mounting ring 2 .

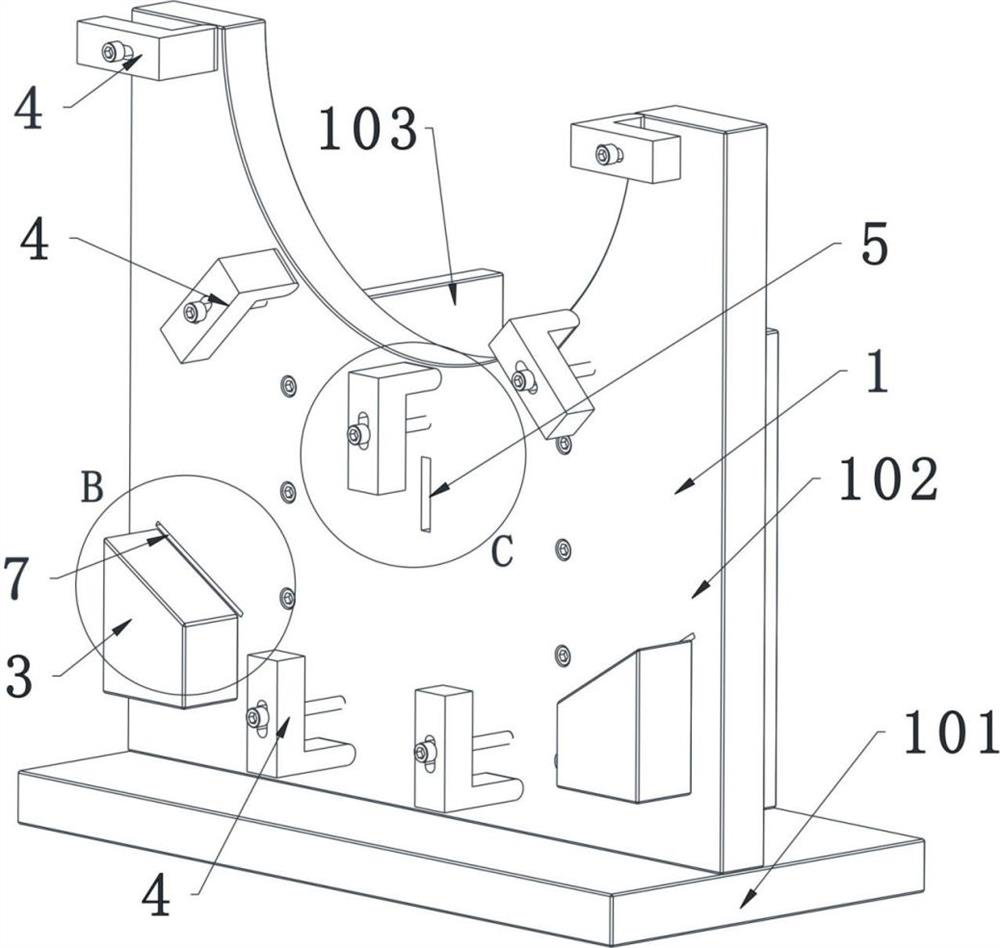

[0044] S3, cleaning the whole pre-processed shroud and the base 1 installed on the machine tool, and checking the state of the base 1;

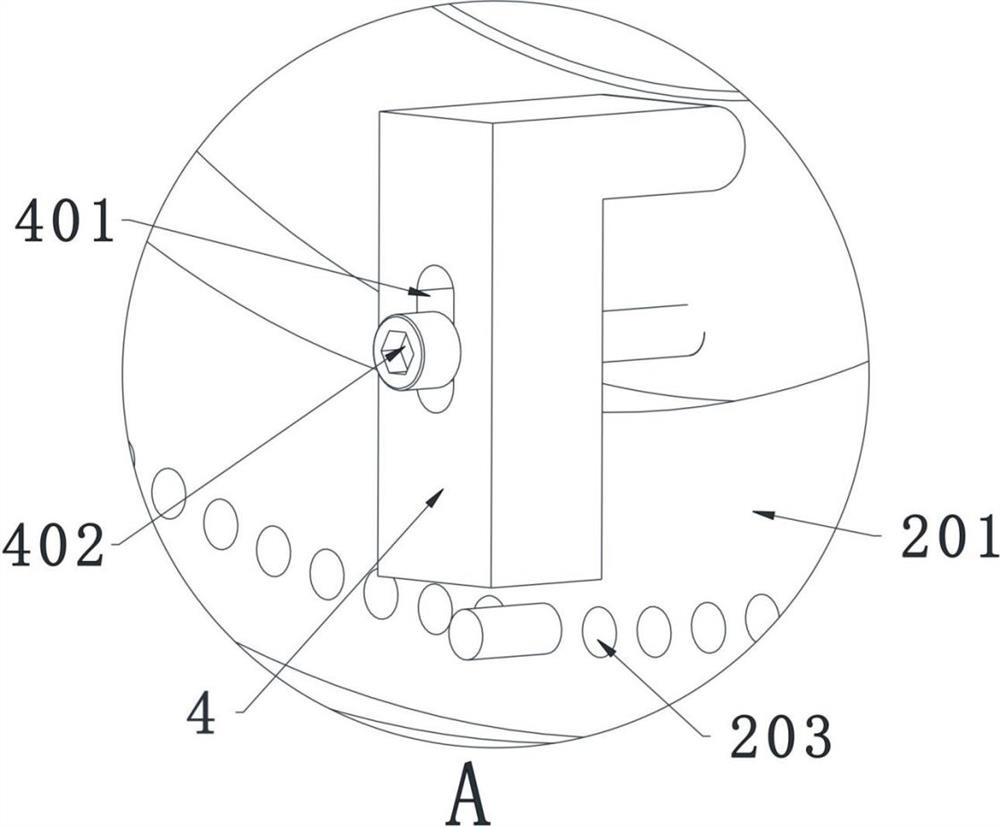

[0045] S4, place the pre-processed shroud as a whole on the receiving block 3, adjust the workpiece mounting ring 2 to make it closely contact with the slopes of the two receiving blocks 3, adjust the angle of the workpiece mounting ring 2 so that any indexing hole 203 is in line with the positioning groove 5 Alignment, and assist and check through positioning pin 6;

[0...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com