Cement stabilized macadam mixture and preparation process thereof

A cement-stabilized crushed stone and mixture technology, which is applied in the direction of sustainable waste treatment, solid waste management, and climate sustainability, can solve the problems of reduced overall structural strength, weak bending and tensile strength, and high cost, achieving remarkable results Economic benefits, prolonging service life and reducing project cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0023] A cement-stabilized gravel mixture, each component and its corresponding parts by weight are shown in Table 1, and its preparation method is as follows:

[0024] Step 1. Weigh the coarse aggregate, fine aggregate, Portland cement, and water of corresponding mass fractions, and place them separately;

[0025] Step 2. Mix the coarse aggregate and fine aggregate evenly, and add water to infiltrate for 1-2.5 hours;

[0026] Step 3, Portland cement and water are stirred separately for 10-30 minutes to mix evenly;

[0027] Step 4. Pour the infiltrated aggregate and mixed mortar into the mixer truck and stir for 5-20 minutes to make it evenly mixed;

[0028] Step 5, after stirring evenly, a cement-stabilized gravel mixture is obtained.

Embodiment 2-9

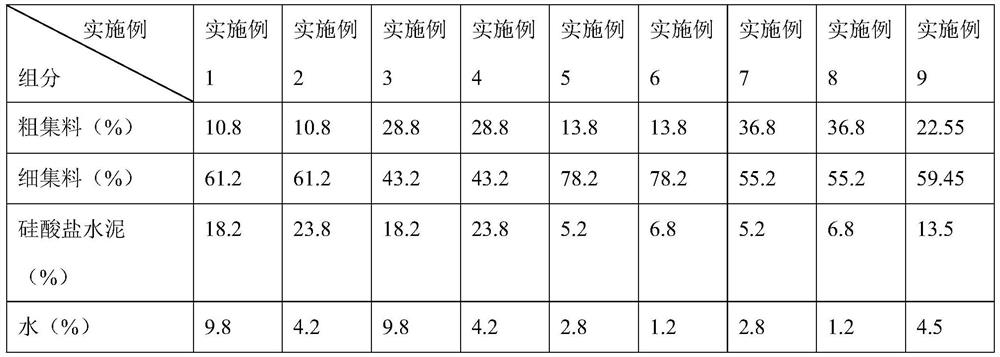

[0029] Embodiment 2-9: a cement-stabilized gravel mixture, the difference from embodiment 1 is that each component and its corresponding parts by weight are as shown in Table 1:

[0030] Table 1: Parts by weight of each component in Examples 1-9

[0031]

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com