Combined arch segment structure, bridge and construction method

A technology of combining arches and segments, which is applied in the field of segmental structure of combined arches, bridges and construction, can solve the problems of complex stress state of the structure, difficult stress concentration location, long half-span arch circle length, etc., and achieves convenient stress analysis. and post-maintenance, high-altitude operations and fewer procedures, ensuring the effect of construction quality and safety

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

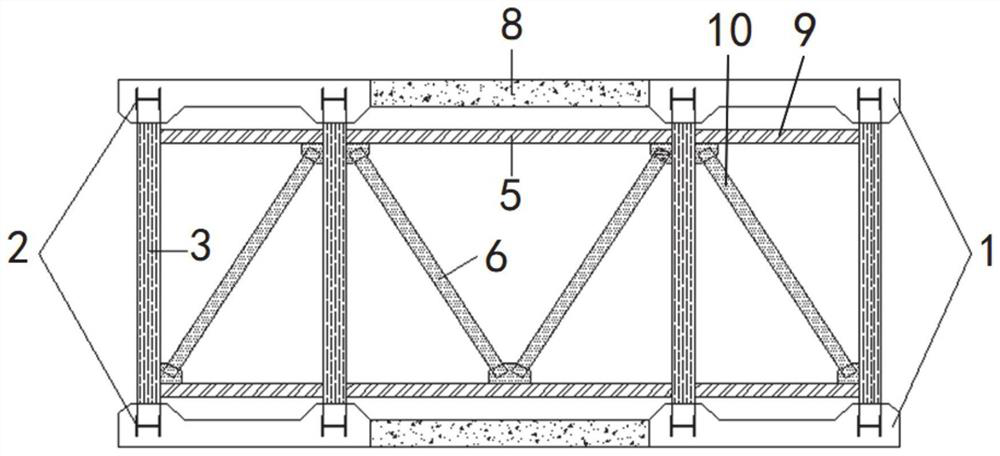

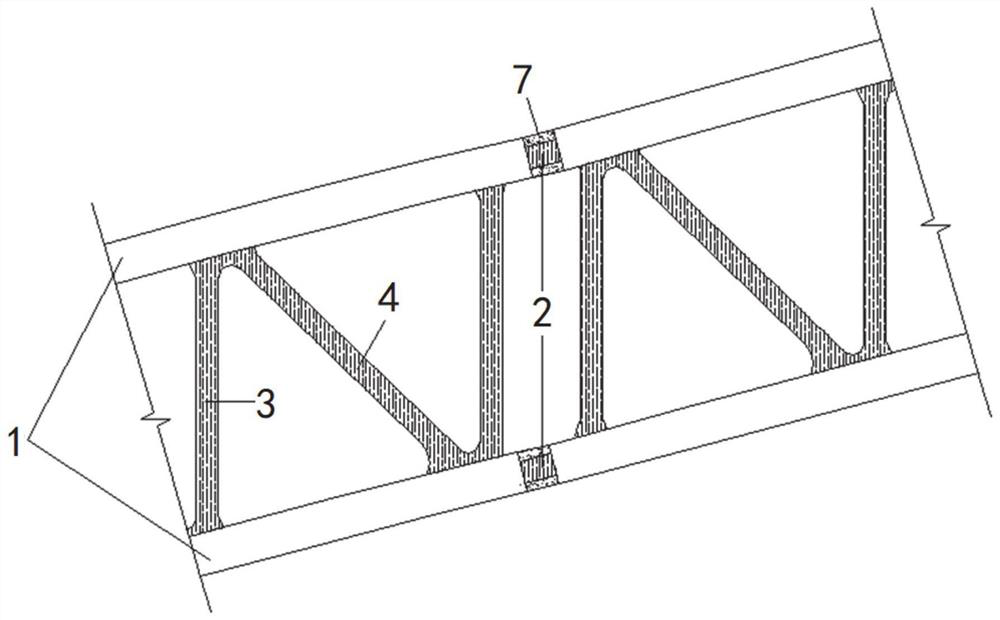

[0030] In a typical embodiment of the present disclosure, such as Figure 1-Figure 3 As shown, a composite arch segment structure is given.

[0031] Aiming at the problems that the current rigid skeleton arch bridge adopts the synergetic force of the concrete wrapped skeleton, the stress state of the overall structure is complex, and there is a risk of web cracking; a composite arch segment structure is provided, and the truss structure formed by steel web members is used to replace the concrete web , The force of the overall structure is clear, which is convenient for force analysis and later maintenance. And because the structural weight is reduced, it is possible to carry out prefabricated assembly construction of large sections.

[0032] The segmental structure of the combined arch mainly includes a middle box and a side box, and side boxes are respectively connected to both sides along the butt joint direction of the middle box, such as figure 1 As shown, from left to r...

Embodiment 2

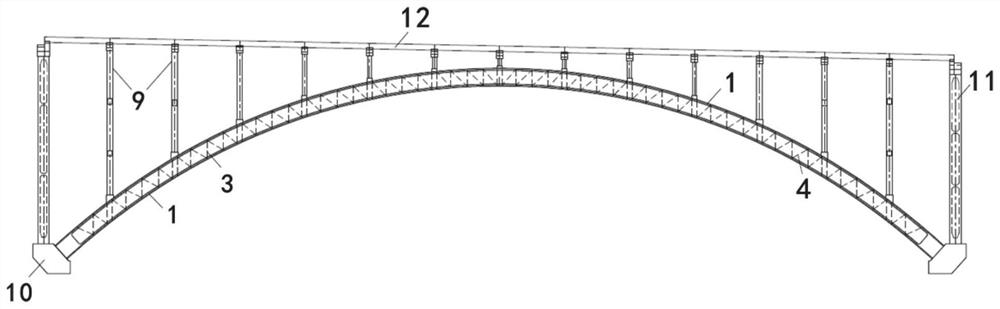

[0055] In another embodiment of the present disclosure, as Figure 1-Figure 3 As shown, a bridge constructed using composite arch segments as described in Example 1 is presented.

[0056] The arch structure of the bridge is sequentially spliced and formed by the multi-segment combined arch segment structure, and other structures can adopt the existing bridge structure.

[0057] For the detailed structure of the composite arch segment structure, please refer to the description in Embodiment 1, which will not be repeated here.

[0058] Compared with the traditional rigid frame outsourcing concrete arch bridge, steel webs are used instead of concrete webs, and only the steel webs need to be painted and maintained in the later maintenance, avoiding the cracking of concrete webs; using prefabricated assembly construction, only need to be prefabricated in the factory After completion, it is transported to the construction site for assembly, with fewer high-altitude operations and...

Embodiment 3

[0060] In yet another embodiment of the present disclosure, as Figure 1-Figure 2 As shown, a composite arch segment construction method is given.

[0061] Include the following steps:

[0062] The arch slab 1, chord 2 and web are prefabricated in the factory, the chord 2 is pre-embedded in the arch slab 1, the web is connected between the two arch slabs 1 arranged at intervals in parallel, and the end of the web is connected to the chord 2 to form Side boxes with webs as trusses and roofs as concrete;

[0063] The arch plates 1 of the two side boxes are connected through the middle plate 8, and the webs are connected through the first cross brace 5, forming a middle box with the web as a truss and the roof as a concrete between the two side boxes;

[0064] The side box and the middle box as a whole are used as a combined arch segment, which is sequentially connected with the joint dragon from bottom to top to form an arch ring, and other structures are built to form a bridg...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com