Directional oil throwing mechanism for compressor and refrigerator compressor

A compressor and oil throwing technology, which is applied to machines/engines, mechanical equipment, liquid variable volume machinery, etc., can solve problems such as poor lubrication effect, eccentric wear and stuck, piston eccentric wear, etc., to avoid lubricating oil mist. The effect of serious change, ensuring a reasonable height, ensuring stability and reliability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

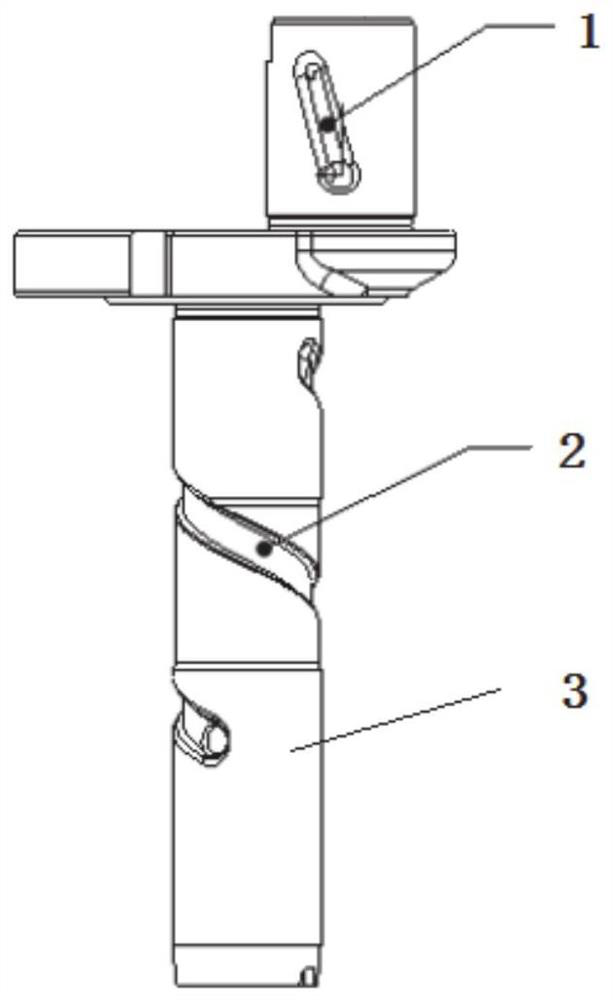

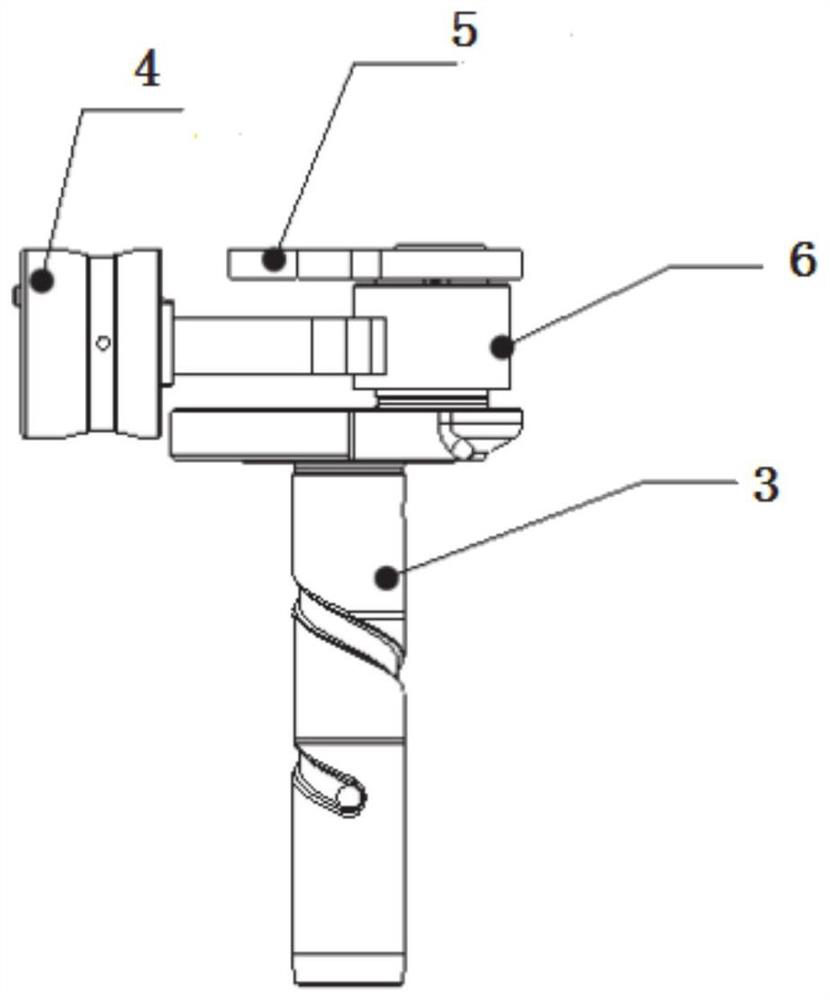

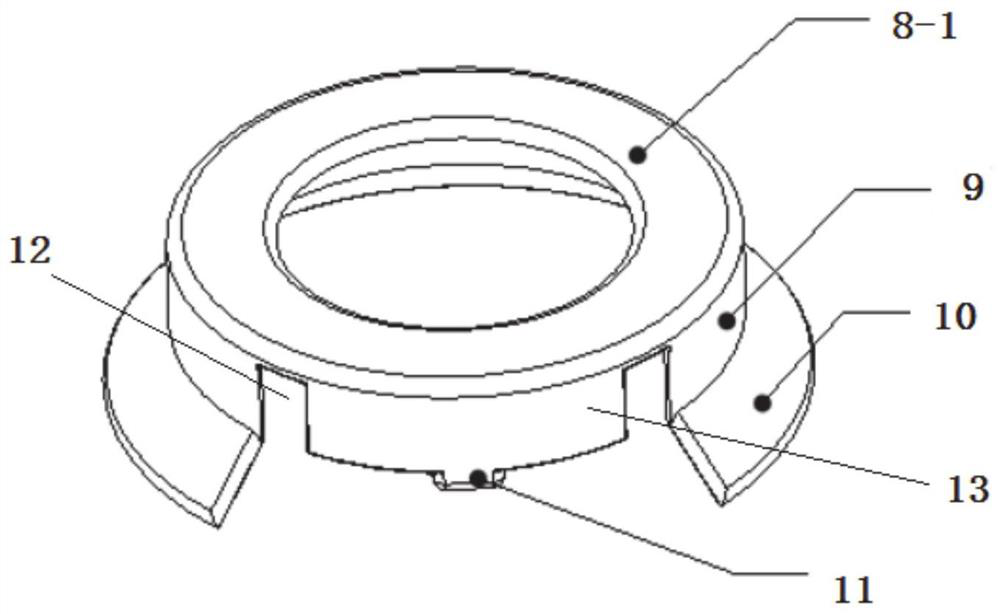

[0041] In a typical embodiment of the present invention, refer to Figure 5-Figure 6 As shown, a directional oil throwing mechanism for a compressor includes a directional cap 14. The directional cap 14 is installed on the side of the crankshaft balance weight opposite to the connecting rod 6, and is arranged opposite to the connecting rod 6. The directional cap 14 is the same as the crankshaft balance weight 5. Matched, the directional cap is connected with the crankshaft balance weight and arranged above the crankshaft balance weight, such as Figure 3-Figure 6 As shown, the side of the directional cap near the crankshaft balance weight 14 has a variable diameter section 10 to control the lubricating oil splash position of the crankshaft oil groove. The ring part 9 of the directional cap is matched with the outer circle of the crankshaft balance weight, and the matching method can be a clearance fit. One end of the ring part is provided with a support, and the support extend...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com