Tubular furnace emergency cut-off valve device with detection mechanism and method

A detection mechanism and valve device technology, applied in the direction of valve device, measuring device, furnace control device, etc., can solve the problems of cracking, flange flying out, unfavorable application and operation, lack of detection mechanism, etc., and achieve compact structure and practicality Strong, simple and convenient operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

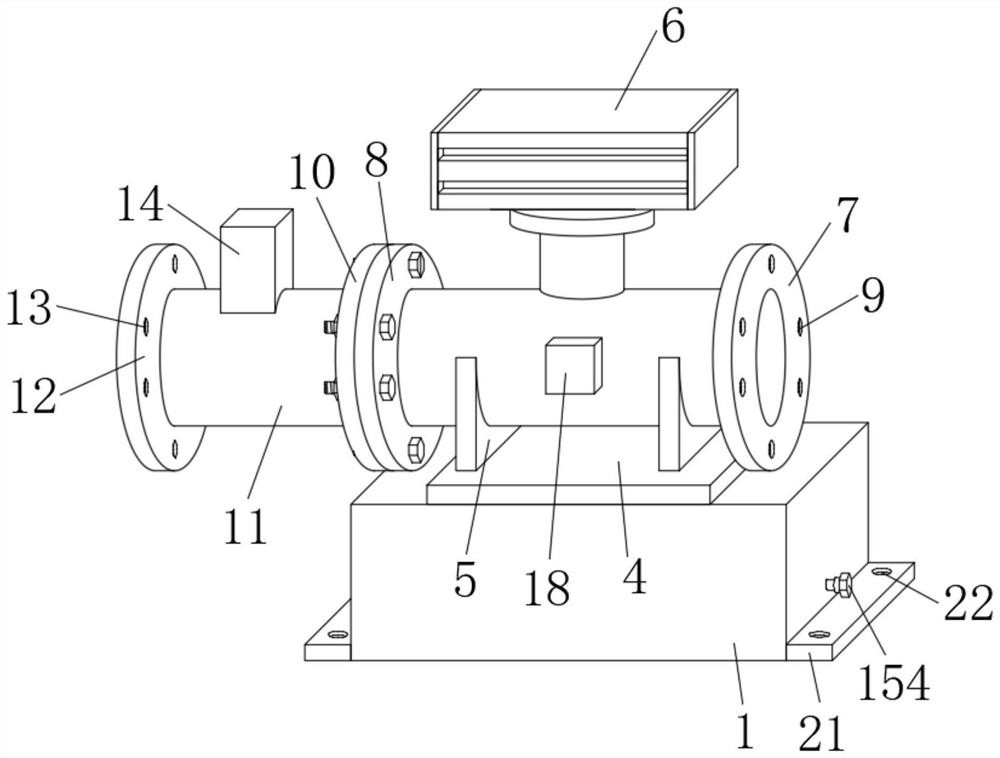

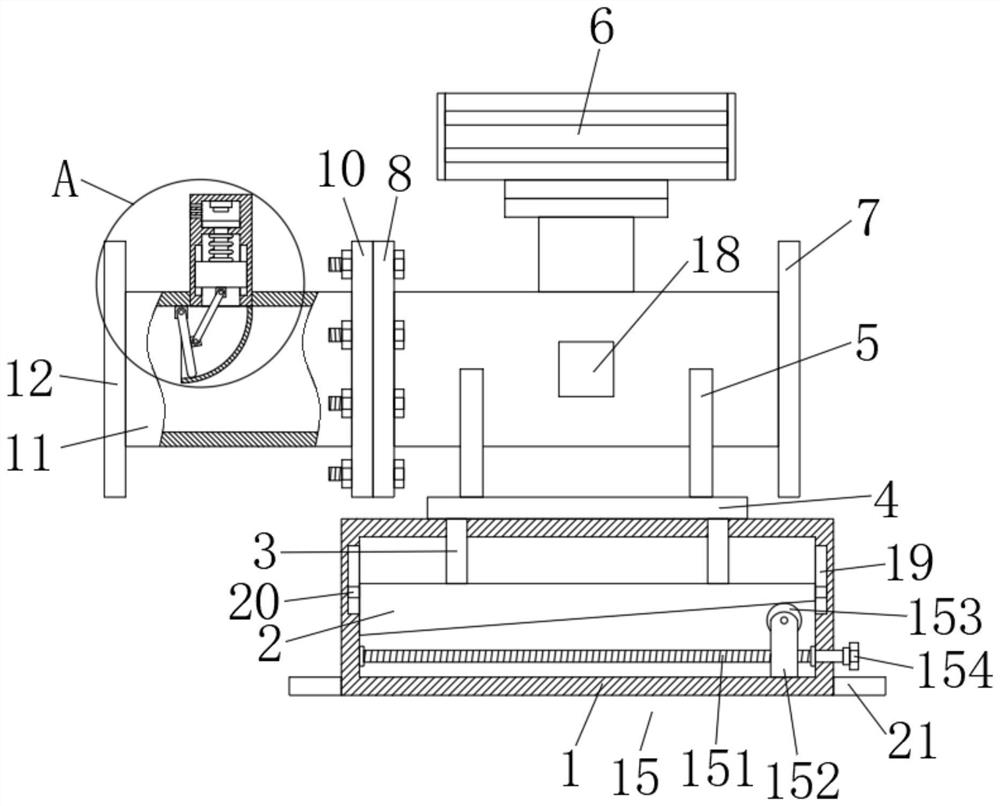

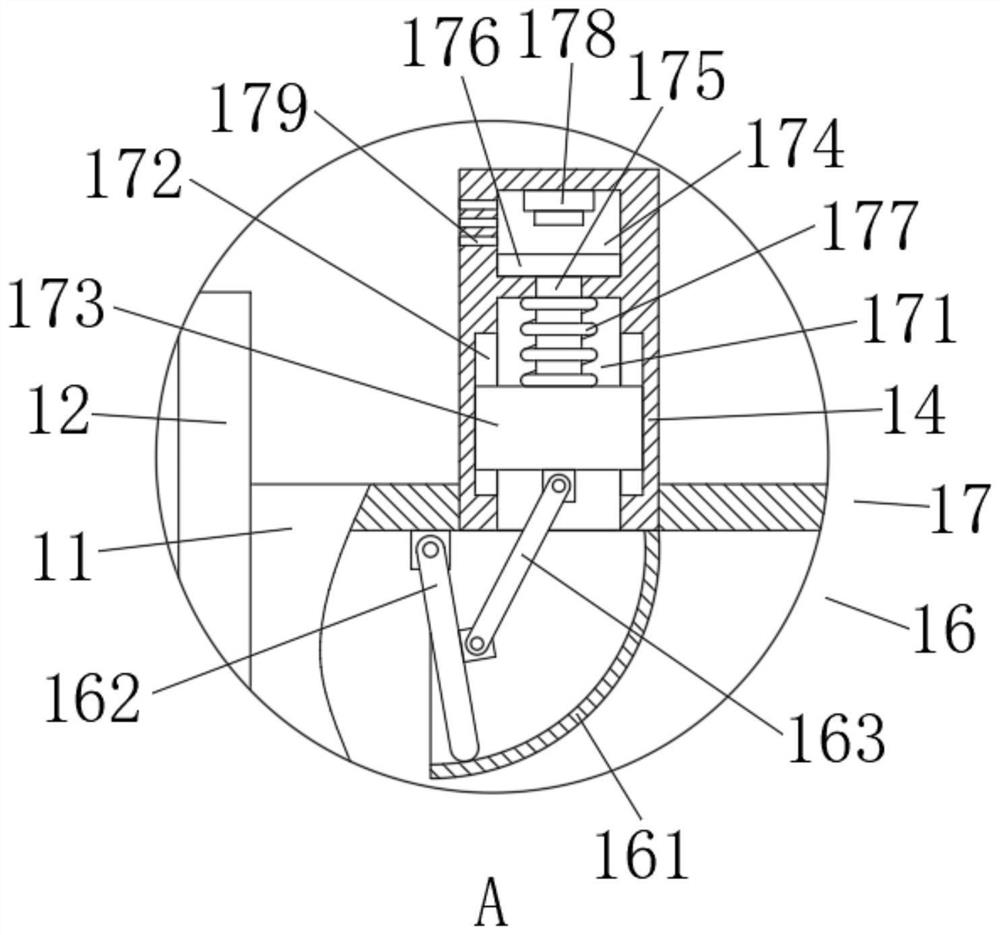

[0027] A tube furnace emergency cut-off valve device with a detection mechanism, comprising an installation box 1, a trapezoidal block 2 is slidably connected to the inside of the installation box 1, and a trapezoidal block 2 is provided inside the installation box 1 and below the trapezoidal block 2. Height adjustment mechanism 15, both ends of the top of the trapezoidal block 2 are fixedly connected with support rods 3, the tops of the support rods 3 all extend to the top of the installation box 1, and the tops of the two support rods 3 are fixed between A fixing plate 4 is connected, and the fixing plate 4 can be better installed on the top of the trapezoidal block 2 through the support rod 3; both ends of the top of the fixing plate 4 are fixedly connected with a vertical plate 5. A shut-off valve 6 is fixedly connected between the tops of the plates 5, and the shut-off valve 6 can be better installed and fixed through the vertical plate 5; the output end of the shut-off va...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com