Fault cause determination method and device, equipment and storage medium

A technology for failure causes and determination methods, applied in biological neural network models, other database retrieval, resources, etc., can solve problems such as low efficiency, lack of clear connections, and inconvenient intelligent decision-making, and achieve accurate and reliable analysis.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

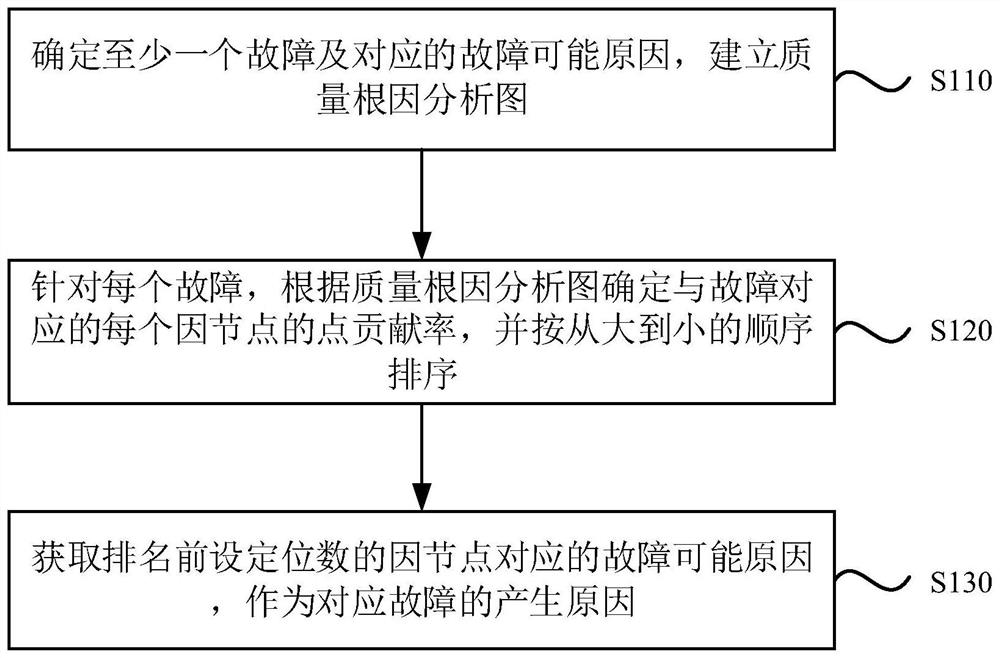

[0060] figure 1 It is a flow chart of a fault cause determination method provided by Embodiment 1 of the present invention. This embodiment is applicable to the situation of analyzing and determining the cause of a fault in an industrial process. This method can be executed by a fault cause determination device. The device can be composed of hardware and / or software, and can generally be integrated into a device with a function of determining the cause of a fault, and the device can be an electronic device such as a server or a server cluster.

[0061] Such as figure 1 As shown, it specifically includes the following steps:

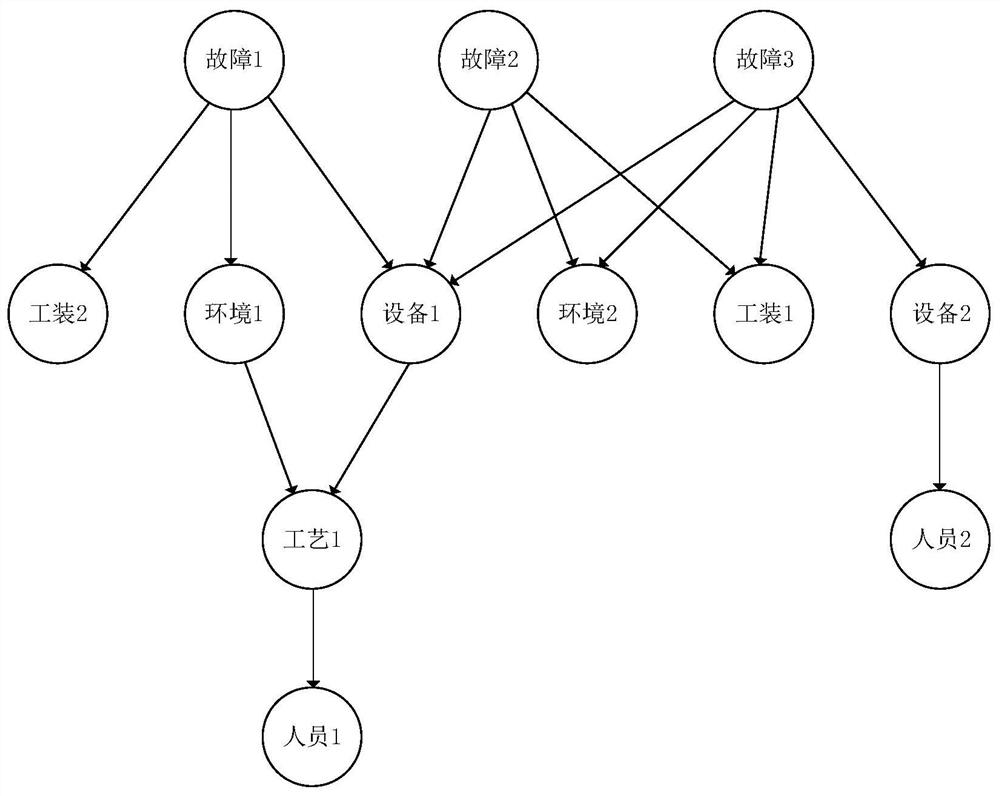

[0062] Step 110, determine at least one fault and the corresponding possible cause of the fault, and establish a quality root cause analysis diagram.

[0063] Among them, the fault can be an abnormal event that affects the production quality or production efficiency in the industrial production process. For traditional manufacturing enterprises, the wor...

Embodiment 2

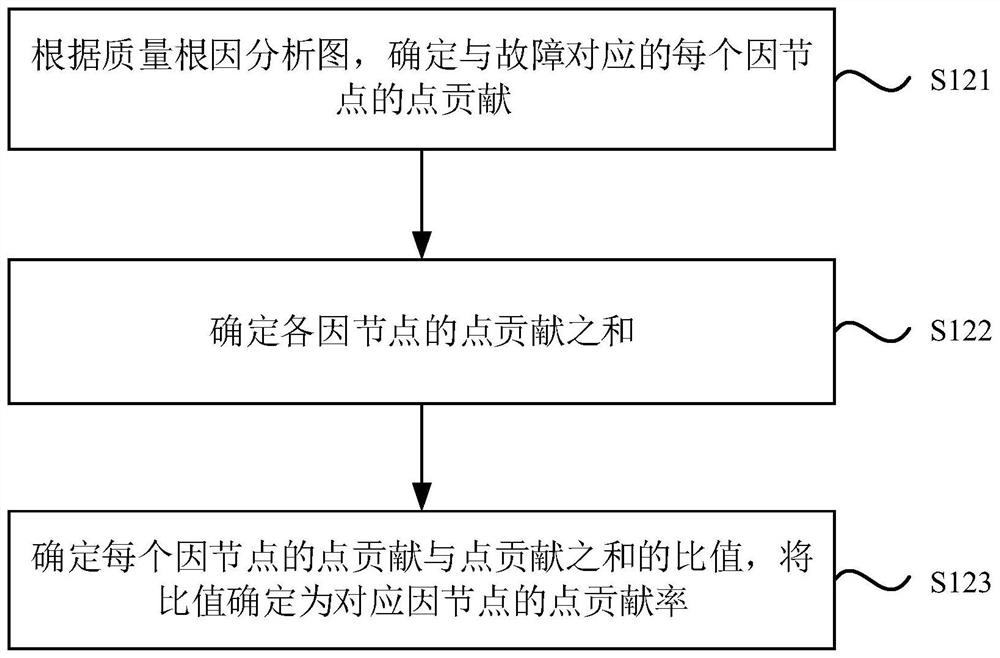

[0080] image 3 It is a flowchart of a method for determining a point contribution rate provided by Embodiment 2 of the present invention. This embodiment is applicable to the case of determining the contribution rate of each fault corresponding to a root-cause node in a quality root cause analysis graph.

[0081] Such as image 3 As shown, it specifically includes the following steps:

[0082] Step 121 , according to the quality root cause analysis diagram, determine the point contribution of each causal node corresponding to the fault.

[0083] In this embodiment, each fault may correspond to multiple causal nodes, and for each fault, the point contribution of each causal node may be calculated.

[0084] Optionally, according to the quality root cause analysis diagram, the method of determining the point contribution of each causal node corresponding to the fault may be: extracting the first-degree node, second-degree node and third-degree node corresponding to the fault i...

Embodiment 3

[0094] Figure 4 It is a structural schematic diagram of a device for determining the cause of a fault provided by Embodiment 3 of the present invention. Such as Figure 4 As shown, the device includes: a quality root cause analysis diagram establishment module 210 , a point contribution rate sorting module 220 , and a cause determination module 230 .

[0095] The quality root cause analysis diagram establishment module 210 is configured to determine at least one fault and the corresponding possible cause of the failure, and establish a quality root cause analysis diagram.

[0096] Optionally, the quality root cause analysis diagram establishment module 210 is also used for:

[0097] Obtain a fault file containing fault information, parse the fault file, and obtain at least one fault; determine a possible cause of the fault based on at least one fault and combined with production process information.

[0098] Optionally, the quality root cause analysis diagram establishment...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com