Object surface flaw detection and analysis method and device based on photometric stereo

A technology of object surface and photometric stereo, applied in image analysis, image data processing, instruments, etc., can solve problems such as poor universality, difficult algorithm design, and low detection accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0064] In the prior art, it is impossible to find flaws by analyzing different kinds of object surfaces through one image processing technology. The surface material, texture, and illumination of the object to be tested are quite different, and the types of defects are diverse. The design of traditional algorithms is difficult, the detection accuracy is low, and the universality is poor, such as scratches and dents on the surface of lithium batteries. It is not easy to be detected; using deep learning technology has high requirements on hardware and requires a large number of rich samples. The present invention discloses a method and device for detecting and analyzing object surface defects based on photometric stereo through the following embodiments.

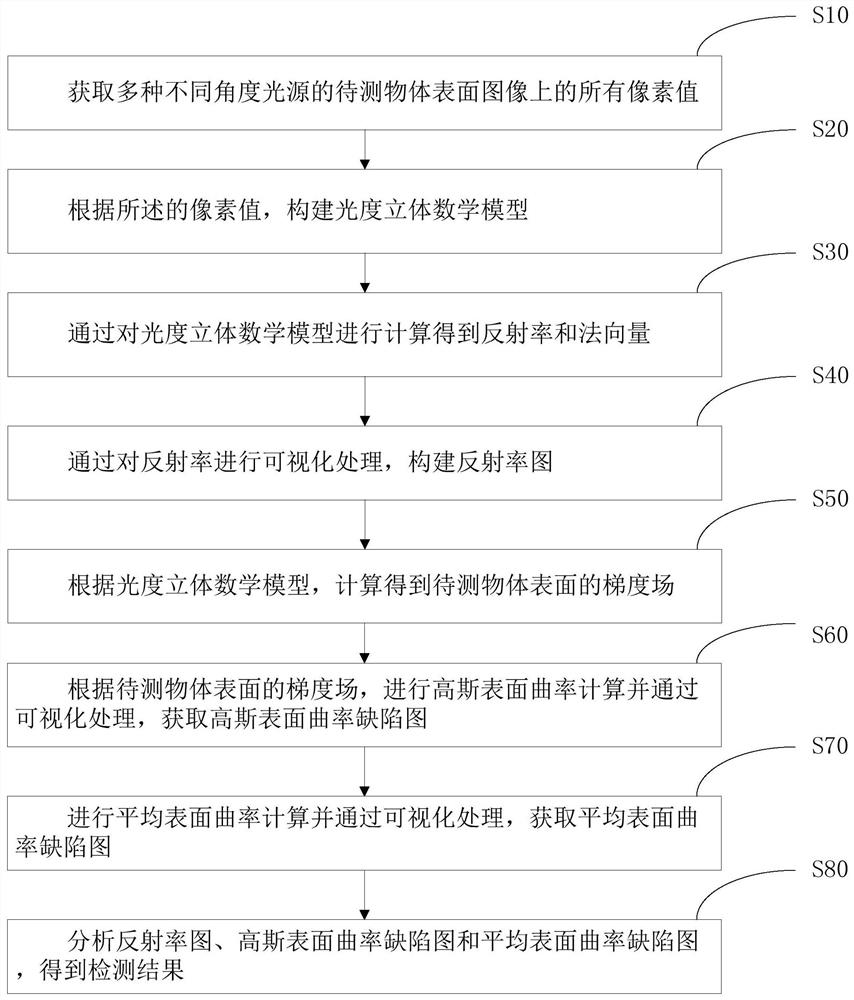

[0065] see figure 1 , is a flow chart of a method for detecting and analyzing object surface flaws based on photometric stereo provided in this application, which is applied to a corresponding device. Such as figure 1 shown...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com