Filter material for air filter

A technology of air filter and filter material, which is applied in the direction of filtration and separation, chemical instruments and methods, textiles and papermaking, etc., can solve the problems of warping and rolling up of laminated non-woven fabrics, and achieve the suppression of warping and rolling up , low pressure loss and sufficient bonding strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

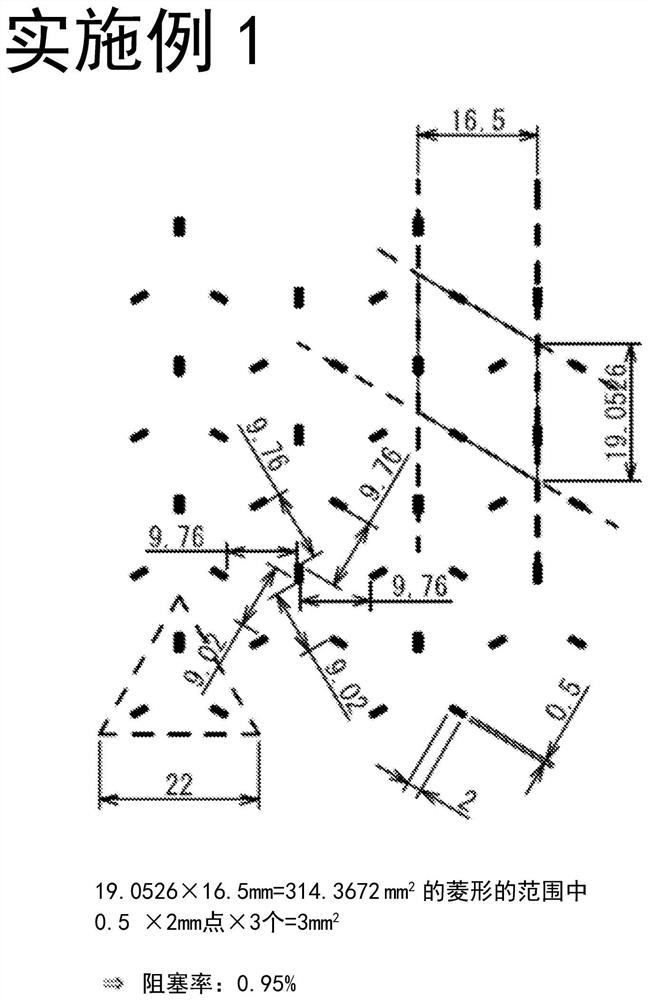

Embodiment 1

[0150] Use gram weight 70g / m 2 Polyester spunbonded nonwovens, and for a grammage of 25 g / m 2 Polypropylene melt-blown non-woven fabric with permanent electrification processing, 0.3-0.5μm counting method collection efficiency at 5.3cm / sec is 99.97% or more, and laminated non-woven fabric is bonded by ultrasonic heat welding , to make a filter material formed of this laminated non-woven fabric. At this time, the pattern as the welded part forms a repeated pattern, and a filter medium is obtained in which the pattern units constituting the pattern are arranged as follows.

[0151] [Explanation about the arrangement of pattern units in Embodiment 1]

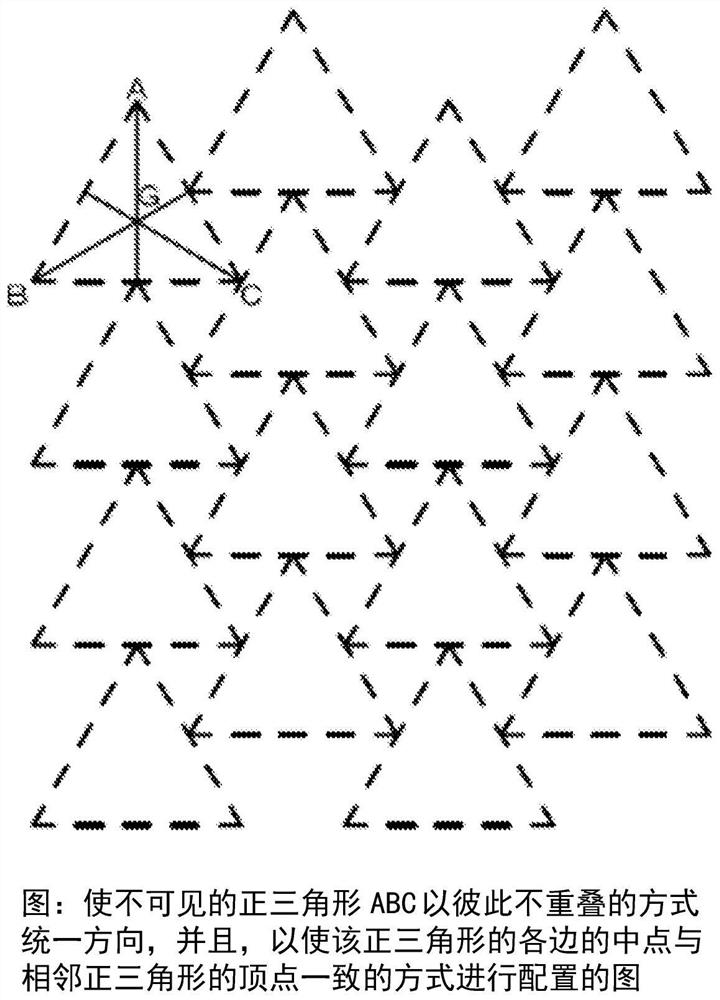

[0152] During the ultrasonic heat welding process, it is arranged in such a way that the directions of the invisible equilateral triangles ABC are kept uniform so that they do not overlap each other, and the midpoint of each side of the equilateral triangle ABC coincides with the vertices of the adjacent equilateral triangles. (...

Embodiment 2

[0153] Embodiment 2, comparative example 1

[0154] Obtain the filter material of embodiment 2 and comparative example 1, embodiment 2 is all the same as embodiment 1 except that the length on one side of the invisible equilateral triangle ABC is 20mm, comparative example 1 is except that the length on one side of the equilateral triangle ABC of invisible is Except for 25 mm, it is the same as in Example 1.

Embodiment 3

[0155] Embodiment 3, comparative example 2

[0156] Obtain the filter material of embodiment 3 and comparative example 2, embodiment 3 is all the same as embodiment 2 except that the size of pattern unit is 1mm * 3mm, comparative example 2 is all the same as that except that the size of pattern unit is 0.5mm * 1mm Example 2 is the same.

PUM

| Property | Measurement | Unit |

|---|---|---|

| softening point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com