Elastic waistline manufacturing device

A technology for manufacturing devices and elastic waistlines, which is applied in the fields of medical science, absorbent pads, bandages, etc., to achieve the effects of good stability, good distribution effect, and high molding accuracy.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0027] The present invention will be further described in conjunction with the accompanying drawings and specific embodiments.

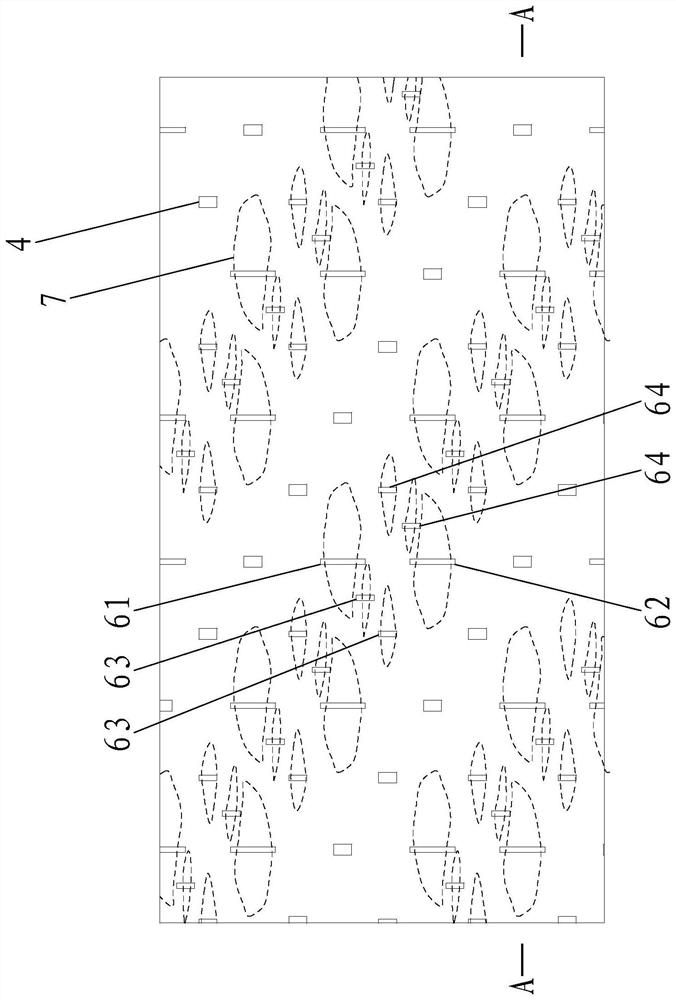

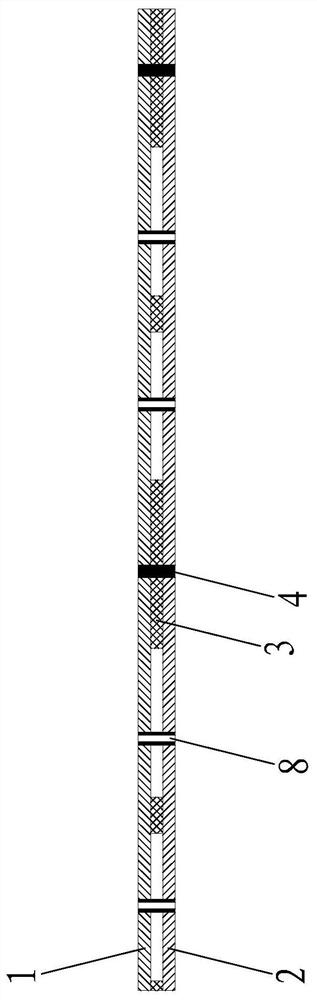

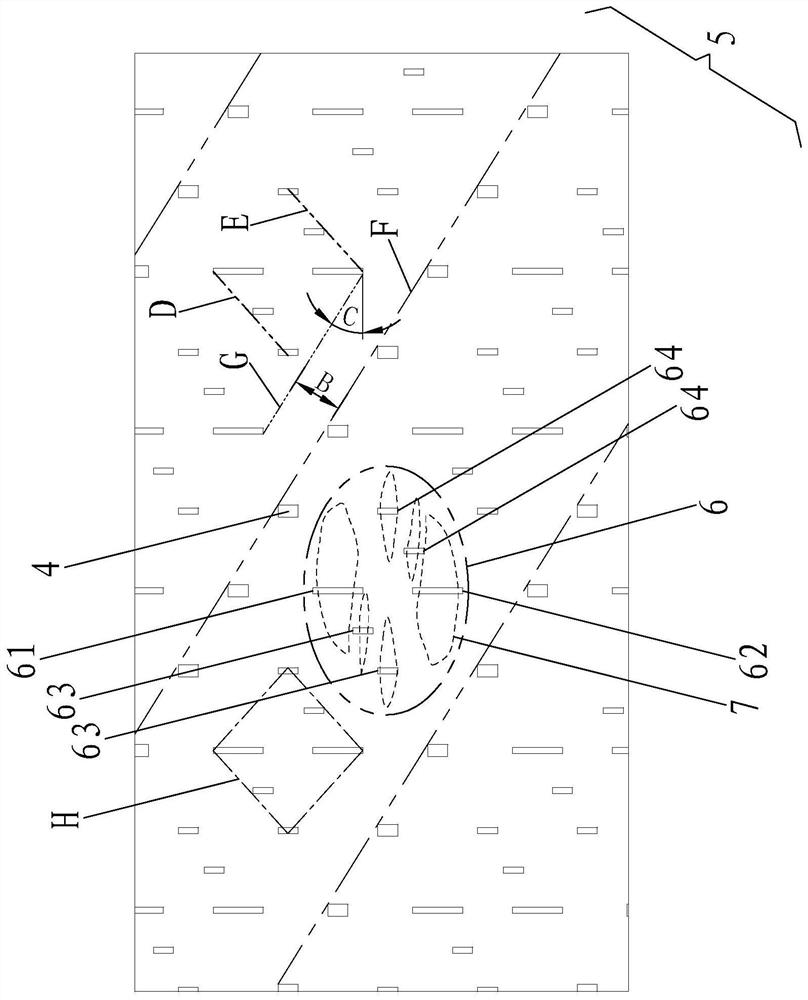

[0028] refer to Figure 1 to Figure 4, the present embodiment provides an elastic waist, comprising an upper non-woven fabric 1, a lower non-woven fabric 2 and an elastic film 3 sandwiched between the upper non-woven fabric 1 and the lower non-woven fabric 2, the upper non-woven fabric 1. The lower non-woven fabric 2 is an air-permeable sheet material, and the non-woven fabric material is selected in this scheme. The upper non-woven fabric 1, the elastic film 3, and the lower non-woven fabric 2 are fixed through a plurality of connecting parts to form fastening points 4, and each fastening point 4 is distributed to form a plurality of partition lines F, and each partition line F is along the Horizontally spaced, two adjacent partition lines F form a partition area 5, there is at least one cutting unit 6 in the adjacent two partition lines, and each ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com